Solenoid valves for water are devices with which you can remotely shut off or open the flow of water, gas and any other medium in the pipeline. These devices are called electromagnetic, because they use an electromagnetic coil (solenoid) for their work. There are several types of such devices and each has its own characteristics and differences in the principles of operation.

The electromagnetic valve is a type of shutoff valves installed on various pipelines, including domestic

Content

The main elements of the solenoid valve and principle of operation

The electromagnetic valve for water and other environments includes such components:

- housing;

- cap;

- membrane and seal;

- plunger;

- stock;

- electric coil.

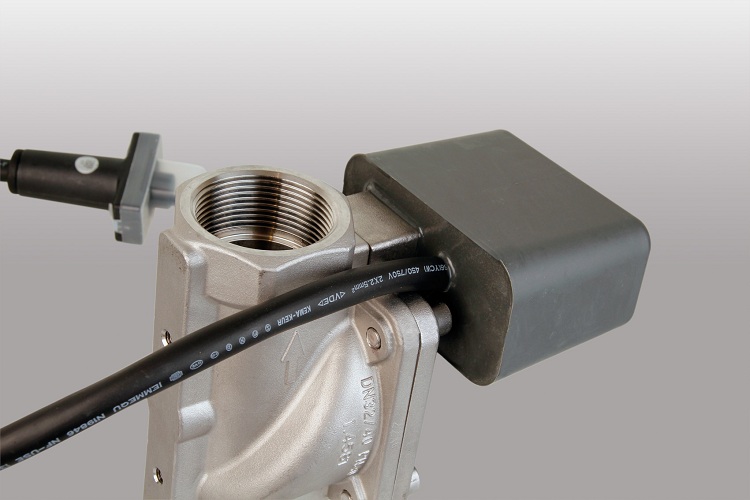

The case of devices, as a rule, is made of brass, stainless steel (to improve anti-corrosion properties) and cast iron. Plastic solenoid valves for water are very popular.

For the manufacture of plungers and rods, materials are used that have magnetic properties. Electromagnetic coils are available in a special protective case, which has high leakage rates. The coil winding consists mainly of copper wire or enamelled wire. The operation of such devices is carried out by applying voltage to the coil.

Membranes of products are made from polymeric materials that have high elasticity.

Such materials include:

- EPDM, NBR, FKM membranes.

- PTFE or TEFLON seals.

The thermal properties of membranes and seals are summarized in table No. 1.

Table 1

| Title | Material | Temperature (min), ° С | Temperature (max), ° С |

| EPDM | Ethylene Propylene Rubbers | –40 | +140 |

| NBR | Nitrile butadiene rubbers | –30 | +100 |

| Fkm | Fluoroelastomer | –30 | +150 |

| PTFE | Polytetrafluoroethylene | –50 | +200 |

| Teflon | Polytetrafluoroethylene | –50 | +250 |

The principle of operation of the solenoid valve for water

If there is a need to shut off the flow of the transported medium, then a pulse is supplied from the control apparatus to the electromagnetic coil. As a result of this signal, the center of the device lowers or rises (it depends on the type of product) and blocks the water. After the voltage disappears, the center returns and the medium resumes movement.

Important! Valves are used in different environments, which have individual indicators of pressure and temperature. The choice of model should correspond to the characteristics of the environment, otherwise the device will not last long.

Application area

The electromagnetic valve is a rather useful device and is used in various fields. Basically, the scope is determined by focusing on the material of which the valve is made.Such products are used in washing machines, sewer systems, in irrigation structures, for monitoring hydraulic systems, in heating systems, etc.

In addition, solenoidal models are used to control and regulate the transportation of a variety of aggressive environments in production. Production devices can have a huge diameter. It is strictly forbidden to use brass products in aggressive environments, such as: acid, diesel fuel.

Benefits of Solenoid Valves for Water

The main advantage of the solenoid valve for water is that its use allows for quick regulation of the transported medium in the water supply system or any other. In order for the product to fulfill its function, only 2-3 seconds are enough. Due to this, the solenoidal model is an indispensable device in the water supply systems of apartments and private houses. It will allow you to control the temperature in the system due to the regulation of water supply.

An electromagnetic product allows you to evenly distribute the temperature in the system and this prevents its contamination. This affects the extension of the service life of the entire heating structure. Due to these characteristics, solenoidal models occupy a leading position in the market of stop valves.

Due to the lack of mechanical parts in the design that quickly wear out and fail, the solenoid device is considered more reliable. It can be installed in systems with different pressure indicators, because this parameter does not affect its operation.

Types and characteristics of solenoid valves

The electromagnetic valve (its types) can be divided into two main categories, which differ by the principle of operation of the on and off mechanism:

- direct action.

- pilot action.

In addition, they are divided into several main types that have functional features. Devices can be:

- normally closed (open). If there is no voltage supply to the coil, it will be constantly located in the closed position. When voltage arrives, it opens the device. A normally open valve acts the other way around - without voltage it does not interfere with the movement of the medium;

- bistable. When voltage is applied, the operating positions are switched.

By the type of coils of the device are divided into:

- DC - the coil of such devices is characterized by a small electromagnetic field strength.

- alternating current - the strength of the electromagnetic field of such a coil is quite large.

Helpful information! There is a special type of device called shutoff. Shut-off models perform the function of instantly shutting down the pipeline or blocking one of the pipes in an emergency.

In addition, the unit, depending on the nature of the operation, is divided into:

- one-way;

- two-way;

- three-way.

One-way ones have one nozzle and do not combine different fluid flows. Two-way have two nozzles (input and output). The principle of operation of one-way and two-way devices is based on the functioning of a cone or ball used for closure.

Three-way solenoid valves for water - have three nozzles and operate by mixing fluid flows. Three-way solenoid valves can also control and regulate temperatures by mixing water flows. In addition, there are explosion-proof models that are used in explosive atmospheres. Such valves are made of durable, refractory materials. There are also vacuum valves.

Electromagnetic coils

An electromagnetic or induction coil converts electricity into translational motion. Most often, there are coils with copper winding on the cylinder. The cylinder includes a magnetic plunger. When a pulse is applied to the coil, a magnetic field arises. As a result of the magnetic field, the center is drawn into the coil.

Some tips for choosing the right device

There are several important parameters that you should pay attention to when choosing a solenoid valve. One of the main indicators is the size of the inlet and outlet. The range of electromagnetic products is very wide. They may have distinctive features in the design. But, as a rule, this does not affect performance. Very popular are one-inch solenoid devices, which have their own throughput rate - up to 40 l / min.

An important role is played by the size of the outlet of the valve, the throughput of the device depends on it

Important! Before you purchase a valve, it is recommended to pay attention to the mechanical regulator, which is built into the device. It can have a different number of modes. The more of them, the more accurately control will be implemented in the system.

If you need a valve with the highest possible throughput, you can purchase an SVR series device. The normally closed valve of this series has a liquid throughput of up to 100 l / min. Prices for different valves differ and are determined by their quality characteristics.

DIY installation of a solenoid valve for water

By the type of connection with the pipeline there are:

- flange valves;

- threaded valves.

When installing and using solenoid valves, you need to remember these important points:

- Before starting the installation of a solenoidal device for water with your own hands, it is recommended to carry out preparatory work. They include pipe cleaning and marking.

- The place for mounting the valve must be in a conspicuous place so that it is freely accessible. The compact dimensions of the solenoid valves simplify this task.

- It is strictly forbidden to install the device if the electromagnetic coil acts as a lever.

- Installation and dismantling of the device is carried out in a de-energized state.

- It is advisable that the water supply system be equipped with a mud filter. This will prevent foreign particles from clogging the product.

- The solenoid valve must not be subjected to stress due to the weight of the pipes.

- There are special arrows on the valve surface that indicate the direction of movement of the medium. Installation is made on them.

- If the installation is carried out in an open area, the device should be protected with special insulating materials.

- For sealing the connection of the valve and the pipe, it is recommended to use FUM tape.

- Connect the device to the mains by using a cable. It must be flexible and have a cross section of at least 1 mm.

Shut-off and control valves should be selected and installed according to the calculations made in advance. One or another type of valve must be used depending on the type of pipeline and the medium transported through it.