The bellows compensator is a device in the form of a flexible insertion element, which is used in various pipeline structures. This product performs a very important function - compensating for changes in the length of sections of a particular communication. Changing the length of the pipes occurs, as a rule, due to temperature effects or due to installation work.

In all types of pipelines in which there is a risk of thermal expansion, expansion joints are installed

Content

Bellows expansion joints - what is it?

To date, bellows expansion joints are operated in various fields of human activity. Among the main such industries can be noted:

- energy industry;

- metallurgical sphere;

- oil refining industries;

- as well as utilities.

Such devices are very important components of various communications and are used almost everywhere where it is necessary to compensate for the thermal expansion of the pipeline. Steel pipes have the lowest coefficient of thermal expansion, and polyethylene products the largest. Compensator for polyethylene pipes is a necessary measure to prevent deformation. It is worth noting that bellows expansion joints for polyethylene pipes are joined with communication through flanges. In addition to its main task, bellows expansion joints perform several more important functions:

- protection of the pipeline from mechanical damage that can lead to pipe deformation and their destruction;

- compensation for deficiencies that may have occurred during communication. As a rule, due to such installation errors, individual sections of the pipeline are not located on the same line with other sections of the communication;

Helpful information! Also, bellows expansion joints can act as a transitional connecting element. In this case, with their help, the pipes are docked with different cross-sectional indicators.

- damping vibrations that occur in communication when moving the working environment through it. It is also worth noting that vibrations in the system are generated not only from the movement of the medium through the pipes, but also from the operation of various equipment;

- providing the desired tightness indicator in transport pipeline structures.

Bellows expansion technology

The most important part of the design of such a device is the bellows. The bellows corrugated tube is usually made of stainless steel.

Stainless steel is a reliable material that has improved strength characteristics, as well as the following advantages:

- resistance to harmful corrosive effects;

- resistance to aggressive chemicals;

- resistance to temperature changes;

- environmental friendliness;

- aesthetics (does not require additional paint treatment);

- durability.

The process of manufacturing a bellows corrugated pipe is carried out in two main stages:

- Thin-walled steel sheets are joined longitudinally by welding equipment, resulting in a cylinder.

- A ribbed surface is formed on the resulting cylinder. Thus, corrugation is performed.

To achieve maximum flexibility of the bellows tube, the bellows walls are laminated. Thanks to such manipulations, the finished product is characterized by high resistance to pressure, but at the same time remains quite flexible.

All auxiliary parts of bellows expansion joints are made of high-strength carbon steel and are characterized by high technical characteristics.

The principle of operation of the bellows expansion joint

In order to understand exactly how the bellows compensator works, you need to learn one important point. The temperature of the transported medium in communication, as a rule, has a clearly defined indicator, while the ambient temperature cannot be stable.

Important! At low ambient temperatures, the pipeline consisting of metal is compressed and shortened, and at high temperature, on the contrary, it expands.

Compression and expansion processes adversely affect communication. Ultimately, a change in the length of the pipeline structure can lead to a loss of the necessary sealing indicators at the joints of the pipes. To avoid such negative consequences, special bellows expansion joints are used that neutralize the deformation effects and prevent the pipeline from losing its performance.

The principle of operation of this device is based on the fact that all additional efforts that appear during the expansion or contraction of other sections of communication are not transmitted further through the pipeline. The bellows compensator takes on this extra effort. Due to this, deformation can affect only certain areas and are not transmitted further through the system. The same can be said about vibrations inside the system. Such products have high elasticity. To date, several modifications of bellows expansion joints are being made.

With the temperature expansion of the pipes, the compensator takes all the load on itself, preventing deformation and destruction of the pipeline

With increasing ambient temperature, the pipeline expands in two planes: horizontal and vertical. Therefore, during installation, it is necessary to correctly fix the sliding and static sections of the system.

Varieties of bellows expansion joints

Today on sale you can find several modifications of this device. The desired type of bellows compensator is selected depending on the operating conditions, namely, the type of load that will need to be stabilized. Consider the main varieties of bellows models:

- weld axial bellows expansion joint (CSR);

- bellows flange compensator (KSF);

- angular;

- gimbal.

- shear.

- starting.

Axial. It is mounted on a direct section of communication between two static supports. Such supports can be of two types:

- intermediate;

- end.

Such a compensator is used to stabilize the deformation effects in the axial direction. It is worth noting that such welded models, in addition to flexibility, are characterized by high strength characteristics.

Consider common errors when installing an axial compensator for welding:

- first of all, an unsuccessful installation may be due to non-compliance with the instructions for its installation;

- the use of a bellows axial compensator for welding in conditions where two pipes are in a state of misalignment with respect to each other;

- the ingress of foreign elements into the interfacial space;

- guide bearings made of low-quality material that contribute to soil subsidence, resulting in axial shifts between the pipes;

- use of CSR in communication transporting a medium with a high content of chlorides. This leads to corrosion of the bellows shell.

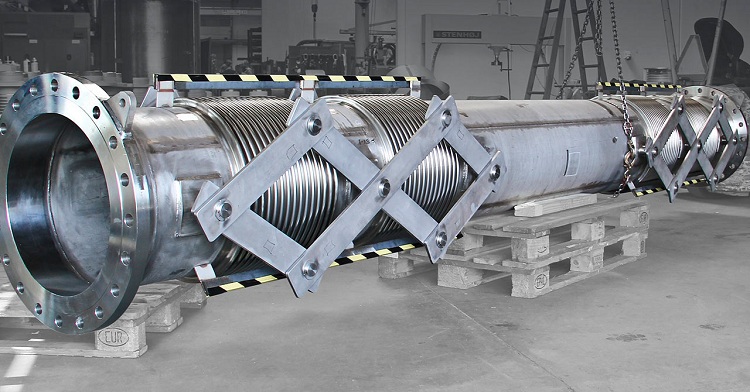

Compensators are available with various types of fastening to pipes, one of the main models is axial, mounted by welding

If you take into account all of the above rules, then the axial bellows (inter-bearing) compensator will last quite a long time, effectively coping with the tasks assigned to it.

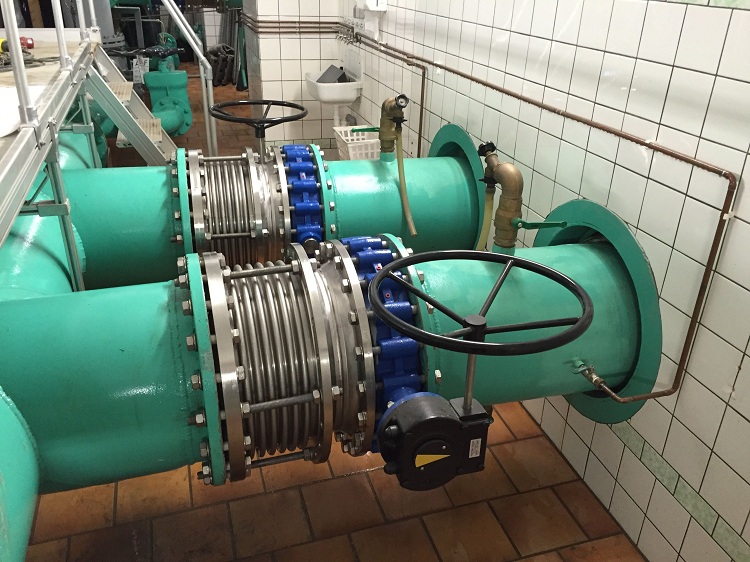

Flanged. This model is one of the most common. It is used everywhere and differs in that for docking with a pipe it has special docking elements - flanges. CSF is used to stabilize axial loads.

Helpful information! It is worth noting that such compensators are distinguished by excellent thermal stability and can be mounted on communications whose ambient temperature reaches 250 ° C.

Compensator bellows axial flange. It is a reliable product that protects pipes from static as well as dynamic loads. CSF is a tensile compound that stabilizes thermal changes in communication length.

Angular. Such models are used to connect communication on the corners. Such a connection can be carried out at different angles. Angular rotary compensators are designed to stabilize the forces arising from the bends of the pipeline structure.

These models are usually equipped with a special hinge element that determines the nature of the movement of the device. An angular model can only move in one plane, excluding axial movements. Thanks to the hinged element, the bellows is also protected from twisting.

Cardan. Unlike the previous model, this device can carry out movement in any plane. It is also worth noting that the cardan model is equipped with two hinged parts. This design allows it to bend in the axial direction.

Shear. Such a compensator is mounted at the points of communication, where a force can arise, which will entail a mutual shift of individual segments of the pipeline structure. One of the most common use cases for such a model is to install it at the entry point of communication into the building. In this case, when the building settles, the compensator will protect the pipe from deformation and prevent an emergency. In addition, the shear device is used to stabilize the shortcomings made when laying communication. Shear models, as a rule, have two bellows, therefore they are also called two-section bellows expansion joints.

Compensator starting bellows. According to its design, it is classified as an axial model, however, it has one difference - it is made with a protective casing, which consists of two parts.

Bellows Compensating Device (SKU)

SKU bellows compensator is made of stainless steel and can be of two types, depending on the design features:

- single section;

- two-section.

Bellows compensating devices are equipped with a special protective case that protects the bellows from mechanical deformation, and also contributes to the alignment of the device.

Such a device, as a rule, is insulated with a special material - polyurethane foam (PPU).Polyurethane insulation is a reliable and modern version of insulation. It is also worth noting that in addition to thermal insulation, SKU is equipped with waterproofing. There are two options for waterproofing a bellows compensating device:

- waterproofing with polyethylene;

- waterproofing with galvanized steel.

Note! Models with galvanized waterproofing are used in communications laid in an open way (on the surface of the earth). And compensating devices with waterproofing made of polyethylene are operated with closed installation of communications (underground).

Consider the main advantages of using SKU:

- such a device does not require routine examinations;

- such products, as a rule, have the same service life as the communication in thermal insulation PPU;

- SKU is allowed to be installed at almost any point of communication, however, it is worth noting that when choosing the location of such a device, it is desirable to provide for the possibility of shifting the protective case over its entire length.

With open installation of SKU, it is mandatory to install a protective box that will protect the compensator from unauthorized access, as well as protect the device from atmospheric precipitation.