Comfort in the house is an important task in its arrangement, and warmth in winter plays a paramount role. In the last 2-3 decades, several alternative options have appeared on the market of heating equipment, replacing old cast-iron "accordions". Many homeowners opt for aluminum radiators that outperform their predecessors in many ways. But it is important to know their features and important characteristics so as not to make a mistake with the choice.

Content

- 1 General familiarity with aluminum heating equipment

- 2 Important technical specifications for aluminum heating equipment

- 3 The main advantages of aluminum radiators

- 4 Features of aluminum heating equipment

- 5 Important requirements for using aluminum batteries

- 6 Expert advice on choosing aluminum radiators

General familiarity with aluminum heating equipment

About 3 decades ago, there was an active search for lighter materials and new technologies to replace old-style heating during repairs. The ideal metal was never found, but new proposals entered the market in the form of bimetallic, steel and aluminum radiators. So the niche of technology for heating the private sector was replenished with innovative heating equipment.

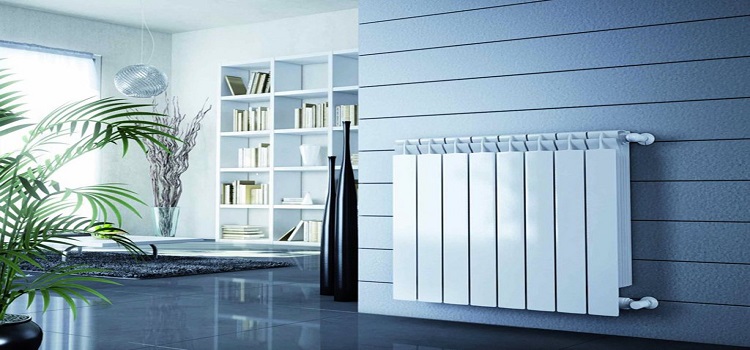

Heating devices made of the lightest metal gave an attractive appearance, so that they began to fit seamlessly into any interior design. The rapid pace of new appliances for space heating began to fill the departments of supermarkets for the sale of coolants, gaining new supporters and adherents.

The novelty was in great demand, mainly due to its low weight, as old cast-iron radiators gradually loosened the brackets in weak walls. However, the heating devices of the new sample turned out to be not without flaws, so they began to refuse them in citywide schemes.

Light radiators - this is the ability to install heating equipment on lightweight walls when building with innovative materials:

- foam block;

- aerated concrete;

- arbolite;

- gas silicate;

- polystyrene foam concrete.

Helpful advice! When installing even a lightweight radiator on drywall, it is necessary to install a metal crate in place of the intended hanging in order to fix the brackets well.

Although aluminum is known for its low specific gravity and high thermal conductivity, it is inferior to other metals in strength, especially in compounds. In addition, he aluminum radiators are subject to deformation due to the increased pressure, which often happens during water hammer tests in urban heating systems at the beginning of each season. However, in the private sector there is no reason to abandon such innovative equipment.

Important technical specifications for aluminum heating equipment

When deciding which metal to choose heating equipment for a country house from, they often prefer light and attractive aluminum-based models.

It is interesting! Judging by statistics, aluminum building heating units are often offered to customers by small construction companies.Usually they are used in the development of the private sector and the replacement of old equipment in summer cooperatives.

Most customers, who did not even hear that there are aluminum radiators, were satisfied. In particular, many are satisfied with the feature of sectional devices for increasing length. This is applicable when it is necessary to increase the thermal efficiency of the equipment, when combining the usable area of adjacent rooms, and also if the efficiency of the boiler or all the thermal equipment is not quite satisfactory.

But if we examine in more detail the properties of aluminum, then it is worth recalling its ability to destroy from various factors:

- the acidic medium of the coolant is able to corrode the surface of radiators, therefore, during their production, internal processing remains one of the most important conditions. If there is no coating inside, then such a battery will fail very quickly;

- this metal is incompatible with copper, which is present in the heat exchangers of boilers, mainly operating on gas, although if pipes and adapters made of other materials are used when installing the radiator, direct contact can be avoided;

- under the maximum pressure specified in the technical documentation for the batteries, heating equipment made of relatively soft and ductile metal can deform at the joints with the pipes, causing a leak.

Everything else is a great option, especially for a private home. Aluminum batteries are usually available in colored form, as the metal has good adhesion and needs additional surface protection. This does not reduce the high thermal conductivity - with such heating equipment, cold winters are not terrible.

The main advantages of aluminum radiators

Each sample of heating equipment has its own excellent properties and shortcomings. Among the obvious advantages of aluminum heating radiators, experts note:

- excellent performance in terms of heat transfer - one of the highest rates among analogues;

- high efficiency not only due to the rapid heating of the metal, but also due to the modern shape of the radiators, which provides convection with additional thermal radiation;

- light weight simplifies transportation of ribbed batteries;

- relatively low cost relative to heating appliances made of other non-ferrous metals, while they do not lose to analogues in all quality indicators;

- compliance with processing and molding - the ability to create streamlined surfaces, which makes it possible to use this thermal equipment in children's rooms and preschool institutions;

- a high level of design and a smooth coating with painting and the possibility of repainting in any color allows you to adapt them to any interior;

- sectional layout simplifies the extension of batteries to the desired length and the choice of model according to the level of heat transfer; aesthetic appearance of aluminum radiators, which look more presentable than the old "accordions" made of cast iron;

- compatibility with temperature controllers and other optional equipment that does not contain copper;

- smooth inner surface with processing is less prone to clogging (organic sludge from the coolant, rust from pipes, calcium scale);

- These batteries have a long life, which can be increased if used correctly, according to the recommendations in the technical description.

Aluminum radiators are a relatively new proposal in the domestic market of thermal equipment. Making a choice in their favor, one cannot ignore the weaknesses mentioned above. These room heating units are made of relatively soft metal - this is their drawback.

Important! Recall the main disadvantage of aluminum - electrochemical incompatibility with boiler equipment containing copper in heat exchangers, which turns metal into powder. Caution is also necessary with heat carriers such as acid-based antifreeze, which loosen the structure of aluminum radiators from the inside.

Features of aluminum heating equipment

Although aluminum radiators are not the most common variety, their popularity among relatively new heating devices is growing markedly. Many buyers are attracted by a good price-quality ratio, as well as the modern design of heating devices.

One can not ignore the features of aluminum, for example, its susceptibility to corrosion from an acidic environment. But this factor is not significant in the area where very soft water is taken, for example, directly from the Neva.

Note! Presumably, the contents of any coolant should be carefully filtered and neutralized from alkalis and acids with special reagents. But this can only be hoped for when connecting heating equipment abroad; we do not always comply with this requirement.

One of the special properties of aluminum batteries is a sufficiently large passage area for the coolant in the collector tubes. The close distance between the sections provides sufficient circulation rates - a guarantee of high heat transfer of a closed loop. But this is achievable if there is a correspondence of the area of the passage section and the diameter of the heating pipes.

If you do not install them on the upper floors of city skyscrapers with a maximum pressure above 10-16 atmospheres, then they will provide heat for more than a dozen years.

Important requirements for using aluminum batteries

The design of these radiators is characterized by a large number of mating sections, their number can be increased. Most often, 10-14 sections are enough to heat a standard living room.

Helpful advice! It is possible to more accurately calculate the power and format of thermal equipment using special programs and formulas using the parameters specified in the technical description of the product.

A battery that is too long, as a rule, does not add power - the heat carrier, which passes all its way, gives off a significant part of the heat. The same can be said about the choice of the largest format for height, when they are purchased not for installation in the window sill, but along the walls - for heating a room with glazed balcony doors.

High thermal conductivity and low inertia of light metal - this is quick heating and slow cooling. This, coupled with a special form of aluminum batteries, gives an additional convection effect to increase their power. High thermal conductivity is due to the transfer of half the heat through direct heating and another 50% from convection of heat waves.

Attention! Despite all the advantages of innovative equipment made of aluminum, the most important requirement remains installation with precise observance of the vertical and horizontal.

Correct connection significantly reduces the likelihood of airing and clogging of sections. But at the same time, it is recommended to install a Mayevsky crane or a bypass air valve to let air out of the last upper manifold. The weakest point is the threaded joints of the radiator sections, where it can leak if aluminum has been exposed to destructive factors for a long period. This only happens if the acidity of the coolant is above an acceptable threshold.

Expert advice on choosing aluminum radiators

In the market of thermal equipment in a large assortment of batteries are European, Chinese and domestic manufacturers. To an inexperienced buyer, all aluminum heating radiators seem approximately the same, only the sizes differ. For those who are accustomed to looking only at the price tags where the country of origin is indicated, it is worth familiarizing themselves with the parameters that determine their cost.

Each buyer chooses the product according to their preferences, of course, the radiator should be suitable for different parameters:

- battery quality, which is determined by the strength of the articulation of sections;

- the dimensions of the thermal block must correspond to the window sill in which they will be installed (if provided);

- the design of the device heating the room fits organically into the interior or will be completely hidden behind furniture and curtains;

- the heat output of the radiator should be enough to heat the room even in a very cold winter;

- the presence of protective spraying on the inner wall, which protects aluminum from destruction (noticeable if you look inside through the collectors).

Price tags are also influenced by brand authority and the country of origin. Although the products of domestic enterprises are the most affordable, no one can vouch for its durability. Rather, it is a summer budget option. For a cottage or a large country house in specialized retail outlets, Italian radiators are usually asked.

If this is an inexpensive model, also look at the weight of the radiator section indicated in the technical description for the model (passport, certificate). The thicker the aluminum wall, the longer the battery should last. The strength of the paint is an important factor, there should be no sagging, cracks and chips. Sometimes the budget price is justified by savings by changing the depth of the sections, less aluminum and paint are used. The standard is 95-100 mm, the economy version is 80 mm, respectively, the heat transfer area is much smaller.

Some popular models and their cost are presented in the table.

Table 1

| Mark | Manufacturer | Features | Section price, rub |

| Global Iseo 500 | Italy | Compact, dual surface coating | From 540 |

| Rifar Alum 500 | Russia | Lightweight alloy, special sectional shape of sectional channels | From 575 |

| Lammin Eco AL-500-80 | Finland | Wide collector, excellent coating quality | From 399 |

| Royal Thermo DreamLiner 500 | Russia | High power, enhanced shock protection | From 378 |

| Global VOX R 500 | Italy | High heat dissipation, ergonomic design | From 596 |

| Rommer Profi 500 | Russia | High quality, suitable for autonomous heating | From 390 |

| Maxterm 500

|

China | Compact, easy to install | From 570 |

Full equipment also adds to the cost of goods. It is recommended that you check for fittings and couplings, taps and jumpers, brackets and plugs. The missing parts will have to be purchased at a retail price, and not the fact that everything will be suitable for the cross-section and type of connection. Obviously, aluminum batteries are a great option for private home ownership. Typically, in a closed circuit, a clean coolant without impurities is used, sharp pressure drops and air admixture are not provided. The only thing that is recommended is to make sure that there is no copper heating element in the boiler with which aluminum is incompatible.