Every year, plastic pipes are gaining a greater niche in the world market. Therefore, the question of choosing elements for their reliable docking comes to the fore. The best solution is to use compression fittings for polyethylene pipes for this purpose. With the help of such parts, parts of a pipeline system consisting of pipes of different diameters and turns, as well as those pipelines that need quick installation / disassembly, are connected.

Content

- 1 Types and Features

- 2 Execution PND coupling compression

- 3 Installation of compression couplings for polyethylene pipes and the advantages of such joints

- 4 Technical characteristics of compression fittings for polyethylene pipelines

- 5 Leading manufacturers of compression fittings for connecting polyethylene pipes

Types and Features

For pipe connections one diameter straight lines are used fitting, and for segments of pipelines that differ in the value of this parameter ˗ transitional. That is, the use of such products makes it possible to increase the length of polyethylene water supply systems when the need arises.

In general, for the manufacture of parts of this type is used:

- cast iron;

- steel;

- brass;

- copper.

As for the connection of pipeline elements made of low-pressure polyethylene (HDPE), in this case compression fittings are used, the polypropylene copolymer being the raw material for their manufacture.

Important! The term "transition fitting" may have another interpretation. Professionals call the element connecting pipe segments on one side with thread and welding on the other. In this case, the transition from polyethylene to metal is implied.

The diameter range of compression fittings for HDPE pipes ranges from 16 ... 110 mm. These parts can withstand pressures of up to 16 atmospheres. They are produced in the most diverse form and can have both internal and external threads.

Compression fittings are of the following types:

- bends;

- couplings;

- stubs;

- saddle compression bends;

- tees.

Using a compression fitting for polyethylene pipes, installation and repair of water supply pipe segments made of polymer grades PE80 and PE100 is carried out.

It is also possible to use these parts in other systems, the working environment of which does not lead to the destruction of polyethylene. Owners of country cottages and summer residents are especially in demand. Indeed, the use of compression couplings for HDPE pipes allows you to create a branched irrigation system for a personal plot. And without using a welding machine

Execution PND coupling compression

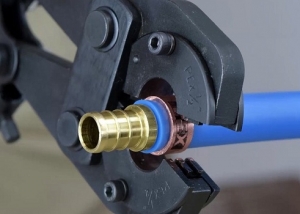

The design of this product consists of:

- corps. As mentioned above, it is made from a copolymer of polypropylene. In addition to the external thread, there is a latch on the case. This element limits the distance that the pipe is introduced into the sleeve;

- o-ring. It is located at the junction. As a raw material for the production of o-rings, nitrile rubber is used. This solution provides absolute tightness of the joints of the coupling with the HDPE pipe;

- clamping ring. It protects the connection from mechanical damage. Clamping rings are made of polyoxymethylene.This material, being harder and stronger than polyethylene, performs additional fixation of the joint so that the joint does not loosen in an unforeseen situation;

- bushings. This element compresses and also holds the o-ring. The sleeve eliminates the possibility of damage to the pipeline with an excessive increase in pressure in the system;

- two nuts. They are made in the form of covers. The connection facilitates the presence of an internal thread. The nuts are designed to close the junction.

This design provides strength and tightness of the connection, but it is very easy to install.

Installation of compression couplings for polyethylene pipes and the advantages of such joints

Compression couplings are fully prepared for installation.

Important! Using these connecting elements, one can not only branch PND pipes, but also change their section.

Do-it-yourself installation of such a part involves the following actions:

- Disassemble the coupling.

- Clean the PND pipe from contamination and make a chamfer on its edge. To do this, it is recommended to use a chamfer. If it is not at hand, a sharp knife is allowed.

- Mark the depth of the pipe entry into the coupling with a marker.

- Moisten the surface of the pipe with liquid soap. Then insert it into the fitting hole. This must be done by applying a small force, since the rubber seal located inside the coupling will provide resistance.

- Tighten the lock nut.

As you can see, the installation of compression couplings for PND pipes is not difficult. But this is not the only advantage of using these products. The masters of household chores give them preference also because such fittings:

- easy to repair. Changing any part in the compression sleeve is easy;

- allowed to be used repeatedly. You can install them more than 10 times;

- characterized by increased resistance to corrosion;

- can be connected with metal elements of the system.

In addition, such products are not high in cost, so their replacement is quite affordable.

Technical characteristics of compression fittings for polyethylene pipelines

Modern industry produces a very wide range of such products. In order for the connection to be leakproof, when purchasing them, you need to know the diameter of the connected HDPE pipes and compare the value of this indicator with the corresponding parameters of the fittings. It will not be superfluous to find out whether their technical characteristics are suitable for the expected operating conditions (for example, the pressure of the working medium). You will find the relevant data in the operating instructions for these parts.

You will find out information about the diameters of the most common compression fittings by examining the table below. The unit is millimeters and inches.

Table 1

| Male thread coupling | Transitional coupling | 90 degree bend | Coupling with inner carving |

PND tee with a female thread | Male thread tee | Threaded nipple |

| 32.0x1.1 / 4 ″ | 110×90 | 110×110 | 110×4″ | 63×2″63 | 63×2″63 | 63×1/2″ |

| 32,0×1″ | 90×75 | 90×90 | 63 × 2 ″ x63 | 50 × 1 1/2 ″ x50 | 50 × 1 1/2 ″ x50 | 50×1″ |

| 32,0×3/4″ | 75×63 | 75×75 | 1/2 ″ x50 50 × 1 ″ | 40 × 1 1/4 ″ x40 | 40 × 1 1/4 ″ x40 | 50×1/2″ |

| 25,0×1″ | 63×50 | 63×63 | 32 × 1 ″ x32 | 32.0 × 1 ″ x32 | 32 × 3/4 ″ x32 | 40×1″ |

| 25,0×3/4″ | 50×40 | 50×50 | 25×1″25 | 32 × 3/4 ″ x32 | 25 × 1 ″ x25 | 40×1/2″ |

| 25,0×1/2″ | 40×32 | 40×40 | 25 × 1/2 ″ x25 | 25 × 1 ″ x25 | 25.0 × 1/2 ″ x25 | 32×1″ |

| 20,0×3/4″ | 32×25 | 32×32 | 20 × 3/4 ″ x20 | 25x, 0x1 / 2 ″ x25 | 20,0×3/4×20 | 32×1/2″ |

| 20,0×1/2″ | 25×20 | 20×20 | 20 × 1/2 ″ x20 | 20.0 × 1/2 ″ x20 | 20.0 × 1/2 ″ x20 | 25×1/2″ |

Helpful advice! Sometimes there may be a lack of pipeline segments. To prevent leaks, it is recommended to purchase parts manufactured by one firm.

Leading manufacturers of compression fittings for connecting polyethylene pipes

In our country, products of Unidelta (Italy) are widely represented. These fittings are completely disassembled. The rubber retaining ring has a snap.There are 4 pointed teeth on the collet ring, which ensure reliable fastening of the pipes in the fitting.

If your system is equipped with cross-linked polyethylene pipes, products from the Rehau brand (Germany) will be the best choice. Equally popular are products from companies such as Irritec (Italy), Astore (Italy), Plasson (Israel) and George Fischer (Switzerland).

The practice of using compression connectors for polyethylene structures has shown a very reliable and high efficiency of their work. Such parts are able to withstand the effects of a variety of chemical compounds and sharp fluctuations in temperature.