Plumbing fittings are fittings that are used to join individual elements of pipeline structures related to plumbing. Each communication requires the organization of transitions between pipes with different cross-sectional indicators, the implementation of branches and turns. The pipelines used for the installation of plumbing are made from different materials. Such pipes fit plumbing fittings, the family of which is represented by a large assortment of products.

Plumbing fittings are connecting, transitional, locking and other parts used in the installation of pipelines

Content

- 1 Purpose and features

- 2 Functional classification

- 3 Plumbing fittings for plumbing and heating communications

- 4 Fittings for steel plumbing and heating systems

- 5 Fittings for copper plumbing and heating systems

- 6 Fittings for metal-plastic communications

- 7 Fittings for polypropylene water pipes and heating systems

- 8 Fittings for plumbing and heating systems made of polyethylene

- 9 Fittings for sewer systems

Purpose and features

Plumbing fittings are used in the installation of pipelines, which include:

- water pipes;

- heating communication;

- sewer system.

Previously, conventional welding (electric or gas) was used to articulate individual elements of the pipeline structure. This method is considered reliable, however, it is not functional.

Helpful information! It will not be possible to dismantle the welded pipes without harming them, therefore, with the development of industry, the ways of connecting the communications improved, which led to the appearance of a wide range of fittings.

Connecting fittings perform various functions, however, all of them are aimed at assembling or modifying the pipeline structure. Consider the main functions of plumbing fittings:

- pipe joint;

- creation of deformation points. Strain points are places that are used to damp vibrations.;

- organization of shutoff valves;

- making transitions between pipes from one diameter to another.

Thus, it can be said that plumbing fittings are indispensable and very popular parts that are used everywhere and have an advantage over conventional welding.

Functional classification

Depending on the installation option, several varieties of plumbing fittings are distinguished. Consider these varieties:

- thread mounted;

- compression;

- mounted using welding equipment;

- crimp;

- installed with special glue;

- mating with pipes by capillary soldering.

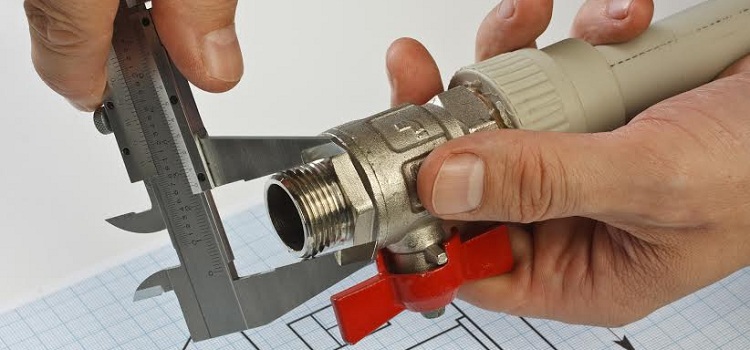

Threaded plumbing fittings are the easiest option. The cost of such products is the lowest. Their installation is carried out in the same way as the assembly of pipes equipped with threaded threads. Today, such parts are used extremely rarely, as they were replaced by more functional and easier to install compression models.

Compression plumbing fittings are similar in design to threaded ones, however, they are equipped with crimp nuts that do the basic job of fitting installation. They have special rubber seals that enhance the sealing performance of these fittings. Of the minuses, it can be noted that during operation, their thread weakens and sometimes you have to tighten the union nuts.

Welded plumbing fittings are mounted by electric or gas welding. For their installation, it is necessary to have welding equipment and possess knowledge and skills in this area.

Adhesive plumbing fittings are usually made of plastic elements and are used for plastic communications. To joint the fitting with the pipe, special glue is used, which has a special chemical structure for reliable bonding. The gluing process is quite simple: the adhesive melts the plastic of the pipe and fitting, after which it cools and a monolithic unit is obtained.

Crimp and press fittings for plumbing are the most popular. This is due to the simplicity of their installation and high performance. But for their installation requires special tools that are necessary in order to deform the crimp ring. Such equipment is expensive. There are crimp fittings without rings, however, they are only a modification of the compression type.

Plumbing fittings that connect to pipes through capillary soldering are considered the most advanced. Such products are equipped with a special element that heats and melts the fitting in the right place. Thus, a reliable connection is formed.

Water and heating systems are mounted from different materials, so fittings are often needed to combine different pipes

Plumbing fittings for plumbing and heating communications

Water and heating systems are mounted from different materials. Consider them:

- steel;

- copper;

- metal plastic;

- polypropylene (PP);

- polyethylene (PE);

Suitable materials are used for different materials. As a rule, for plastic pipes, connecting elements from the same materials are used.

Note! Copper pipes require fittings of the same material. This is due to the fact that with the combination of various metals (for example, copper and steel), an oxidation process occurs. As a result, the risk of leakage at the joints increases.

Today, polymer pipelines and shaped elements for them are very popular, as they differ in many advantages. Consider the main advantages of plastic communications and fittings:

- resistance to corrosion;

- smooth inner walls, which exclude the possibility of salt deposits and overgrowth of the lumen of the pipeline;

- affordable cost;

- light weight due to which they are easy to transport and assemble;

- long service life.

Fittings for steel plumbing and heating systems

Two types of pipes can be attributed to this category:

- galvanized (coated with a protective anti-corrosion layer of zinc);

- black steel pipes.

As a rule, individual elements of pipelines made of black steel and galvanized are joined together by welding, however, this does not always happen. For example, galvanized steel piping is recommended to be assembled using threaded connections. This is due to the fact that welding damages the protective anti-corrosion layer, and this is fraught with the appearance of rust at the joints of pipes.

To connect pipes made of black and galvanized steel, two types of connecting elements are used:

- threaded;

- compression.

Threaded. There are threaded fittings of various configurations: couplings, angles, tees, crosses, etc. Such connecting elements are made, as a rule, of brass or cast iron. Brass products are often subjected to chromium plating to improve their anti-corrosion performance. The main advantage of such parts is a high coefficient of mechanical strength, and of the minuses, it can be noted that the installation of such fittings is quite time-consuming.

Compression. The composition of such connecting devices includes a rubber or silicone gasket, which provides high sealing performance when tightening the nut. The cost of compression models is higher, but they provide a simple and quick installation in problematic areas of the pipeline structure. The main disadvantage of such devices is the low joint strength.

Fittings for copper plumbing and heating systems

Copper pipes are a more expensive option, however, and the quality of the copper pipe is much higher. Consider the advantages of using copper pipes for heating and water supply:

- good corrosion resistance;

- presentable appearance;

- wide operating temperature range;

- presentable appearance;

- long service life (up to 50 years or more).

The individual elements of the pipeline structure are connected using a gas burner. Such soldering involves the use of flux and solder. Among the plumbing fittings for copper pipes, the following products can be distinguished: crosspieces, tees, corners, solder bends.

Before starting the connection of pipes, one of them is rolled to obtain a sleeve that allows insertion of one pipe into another.

Fittings for metal-plastic communications

Metal-plastic pipelines are made of pipes, the structure of which resembles a pie. They consist of the following layers:

- inner polymer layer;

- the middle layer, which is represented by aluminum (in some cases, another metal);

- outer polymer layer.

Note! Such pipes are transported in bays. This eliminates the coalescence of short segments.

Consider two options for the connecting elements that are used to make a fork in the pipeline structure or to connect communication to plumbing equipment:

Compression. For metal-plastic systems, slightly different compression fittings are used than for steel counterparts. The aluminum layer of the pipe is highly plastic, so the installation process looks like this:

- A flare nut as well as a split ring must be fitted to the calibrated end of the pipe.

- Next, the fitting of the connecting element must be inserted into the pipe.

- Then the nut is tightened on the fitting and, thanks to the crimp ring, provides the necessary tightness of the connection.

The advantage of this installation is that it is easily done using simple tools that can be found in every home. It is very important to remember that such a joint is categorically not recommended for heating pipes or water pipes transporting hot water, since it will soon begin to flow.

Press fittings. To install a metal-plastic pipeline using press fittings, you need a special crimping tool. The pipe is fixed on the fitting with a sleeve, which provides high sealing performance both for cold pipelines and for hot ones.

Fittings for polypropylene water pipes and heating systems

Polypropylene is a modern polymeric material that has gained great popularity in the installation of plumbing systems. Fittings for polypropylene pipes, as a rule, consist of the same material. Consider the process of installing a fitting on a polypropylene pipe:

- The outer surface of the pipe and the inner are fused with a special low-temperature soldering iron. The soldering iron should have a nozzle of the appropriate diameter.

- Next, you need to connect the two above surfaces. The result is a monolithic joint.

Polypropylene pipes and connecting elements are of affordable price, however, they are recommended to be used only for systems transporting cold water. They can also be used to organize autonomous water supply and heating. In structures docked with a common riser, water hammer may occur, which in some cases leads to depressurization and leakage.

Fittings for plumbing and heating systems made of polyethylene

There are different options for polyethylene material. Regular polyethylene is used only for the installation of plumbing systems transporting cold water. Consider the fittings that are used in the installation of polyethylene pipes.

Compression. Such products are made from the same material as the pipes and are usually equipped with a rubber gasket. Their installation is quite simple. It does not require special tools and experience in this matter. In addition to polypropylene fittings, on sale you can find brass products that are used for pipes made of low pressure polyethylene (HDPE).

Electric welded. Equipped with a heating element, through which the connection with the pipes is performed. After the assembly of the pipeline, voltage is supplied to each pair of contact terminals, which allows a reliable connection.

Low temperature soldering. This method is not so popular, because it is not always possible to purchase a connecting element mounted in this way. The price of such fittings is quite low.

For water pipelines transporting hot water, another type of polyethylene is used - cross-linked polyethylene. The following properties distinguish it from ordinary material:

- high strength characteristics;

- excellent indicators of thermal stability.

The installation process of such communication is as follows:

- First of all, it is necessary to stretch the pipe and put it on the fitting.

- Further, there is a crimping, which is performed due to the effect of molecular memory.

- At the last stage, it is necessary to further secure the connection with the sleeve.

Fittings for sewer systems

Sewer communication is mounted from the following materials:

- cast iron;

- polyvinyl chloride;

- polyethylene;

Cast iron pipes have recently been globally replaced by polymer ones, since plastic is much cheaper and easier to install. In addition, polymer products have very smooth inner walls that increase system throughput. It is also worth noting the resistance of these products to corrosion.

The sewer systems themselves are classified according to the place of installation on:

- outdoor;

- internal.

Consider the options for fittings that are used for sewer systems of different materials.

Fittings for cast iron pipes. For the installation of cast-iron sewer communications, chasing is used. Consider this process in more detail:

- First, insert the end of the pipe into the socket of the connecting fitting.

- Next, the free space between the pipe and the connecting fitting is chased. Chasing is performed by a heel, which is an organic fiber, impregnated with oil.

- After that, cement mortar is applied to the junction.

It follows that the fittings for cast-iron sewer structures are a combination of outlet with the same cross-sectional indicators as for pipes.

Helpful information! Modern fittings for cast iron pipes are equipped with rubber sealing elements, for increased joint sealing.

Fittings for PVC and PE pipelines. The fittings for PVC and PE pipes are equipped, as in the previous case, with special sealing elements for tightness.

When joining pipes from these materials, it is recommended to remove the outer chamfer from the nozzle. Otherwise, the pipe will be very difficult to insert into the socket. Specialists also recommend the use of special sealants in order to enhance the tightness of polymer sewer pipes.