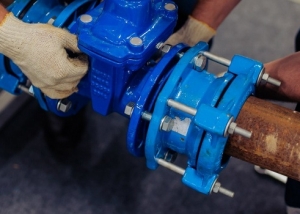

Repair clutch - a special metal or polymer compound that is used to quickly eliminate leaks in various kinds of pipelines. Large or small leaks can occur in piping systems due to mechanical damage, caused by corrosion or freezing of the working fluid. The use of special joints during repair allows reliable sealing of the damaged area.

Content

Classification of repair couplings

Repair couplings are simple but extremely useful devices that can be used to quickly eliminate leaks in a pipeline system. In addition, they are widely used as connecting fittings, ensuring the laying of pipes of the same diameter.

There are several different classifications of these fixtures for repairing piping systems.

By the type of compounds, they can be:

- threaded;

- with rubber o-ring;

- on glue. The tight connection is ensured by the use of special glue, the coupling is not provided with either a thread or a rubber seal;

- welded. It is generally accepted that this type of connection allows you to achieve the highest level of tightness. But, unlike other types of couplings, welded ones require the use of special equipment. They are unlikely to be suitable for those who carry out repairs on their own, with their own hands.

According to the type of construction of the coupling, there are:

- Sliding. The device is put on the free end of the pipe and moved along it to the desired section. As usual, they are used during repair work of the pipeline system, when it was decided to replace a certain section.

- Collapsible (two-part and three-part).

Benefits of Using Repair Couplings

Repair fittings do not require special equipment for installation. By installing a simple fixture, you can avoid replacing the entire pipe. Savings are achieved not only due to a significant difference in the cost of structures. It takes much less time, it is not necessary to suspend for a long time the functioning of the whole section of the pipeline. You do not need to attract specialists and special equipment.

In addition to these factors, the use of a coupling for repair has some more advantages associated with such advantages of a simple device, such as:

- speed of installation, taking no more than a few minutes, without the use of special tools;

- tightness of the installed connection, which will be reliable and durable;

- universality. Can be installed on pipes that are made of different materials, regardless of the nature of the working environment of the pipeline;

- durability of work. In view of the high requirements for repair fittings, it is customary to select high quality materials for its manufacture. Moreover, the design provides for the possibility of repeated use. The only part that needs to be replaced if the product is reused is the seal.

Materials for the manufacture.Advantages of polymer couplings

The materials used for the manufacture of couplings for repair can be divided into two groups:

- Metals and alloys: brass, copper, steel. Cast iron.

- Polymers: polyvinyl chloride, polypropylene, polypropylene.

Repair polymer couplings are widespread due to the general popularity of polymer designs. Their undoubted advantages include:

- ease of mounting, consisting in a dense insert of the part;

- insignificance of weight. Such fittings are easy to deliver, assemble and secure;

- non-susceptibility to destructive corrosion phenomena, the effects of ultraviolet radiation, the influence of an aggressive working environment. Neither water, nor temperature differences, nor overgrowing affect the reliability of the work. Polymeric products are guaranteed to operate for four to five decades.

It is customary to strengthen polymer repair couplings during installation with the help of synthetic sealants. The latter generally gained wide popularity and are used almost everywhere. But synthetic sealants have an unpleasant feature for repair: they can be squeezed out under strong pressure of the working medium.

Repair metal couplings

For pipe repair, when the highest reliability of the installed joints is required, it is preferable to use cast iron or steel joints. Their application allows to eliminate such problems in the operation of the pipeline as the appearance of fistulas, cracks and cracking of pipes, cast-iron and steel, asbestos-cement and reinforced concrete.

Cast iron and steel couplings are also successfully used to eliminate leaks of polymer pipes of all types caused by various reasons:

- mechanical damage;

- breakdowns;

- the formation of longitudinal cracks;

- non-compliance with the technology of welding joints.

The use of cast-iron joints in the repair of a polymer pipeline eliminates sagging pipes, axial displacement and the possibility of a break at the site of damage. Neither limited space nor adverse environmental conditions will prevent the implementation of repairs, which, moreover, will not require a suspension of the pipeline.

It is customary to use steel hydraulic convoluted couplings when it is impossible to avoid sagging or deflection of pipes. Their use ensures that even in such conditions the tightness of the joint is achieved. Metal screw couplings quickly eliminate large leaks. When increased strength and reliability is required, especially when repairing gas pipelines and oil pipelines, it is desirable to use steel welded couplings.

If you encounter problems in the operation of the pipeline system, do not rush to replace the whole area where damage is detected. If you use a repair coupling for pipes, then the result will be achieved with little effort. Repair does not require much time and the involvement of third-party specialists.