An important element for connecting high-pressure hoses, which is responsible for branches and building up additional new fragments of the pipeline, is a connecting fitting. But the scope of their application is not limited to this. Often this is the only way to connect the WFD to hydraulic cylinders, manometers or pumps. The market offers these parts in different designs to fit all kinds of hoses and flexible pipes, not only in living quarters, but also in outdoor bends.

The fitting is a connecting part that allows you to quickly connect a sleeve or hose to the system, create an additional branch, connect various devices

GOST for various types of connection fittings

The name "fitting" is not familiar to everyone, although many have seen the part itself. This is a word of German origin, from stutzen, which in translation means "layering, process or branch pipe". This is a common module for joining or branching pipeline sections. The connecting unit is structurally simple - the fitting itself and the clamping sleeve. They are also used separately to join pipes and hoses. In the integrated method, the fitting and the sleeve constitute one part.

When connecting equipment to communications, for example, a gas stove to the pipeline, integrity and safety violations are unacceptable.

Any poor-quality connection of the pipeline is a danger to users, unjustified costs and a high probability of equipment loss. To prevent such situations, there are special devices, such as fittings, which are responsible for high-quality installation. Nodal connection is made by different methods, and this is the main advantage of this important spare part.

The reliability of the connection of the parts of communications and branches is calculated and described in the state standardization system for each type of combination of parts of the system:

- threaded fitting for welding with one-way connection and on the thread on the reverse side - GOST 24092-80;

- through passage for welding, on threads from the opposite end - GOST 24092-80;

- checkpoint with threaded connection on both sides - GOST 21856-78;

- direct soldering for axial mounting - GOST 26337-84;

- transitional with transfer to a larger or smaller diameter with thread on both ends - GOST 21857-78;

- screwed under the cutting ring, on the threaded connection on the reverse side - GOST 24504-80.

Note! In each description of standardization, the basic parameters for the application of this part, the joint points for each type of hose, hose or flexible pipe are regulated.

Varieties of fittings

Main classification:

- Connecting fitting for high pressure hose (joint of sleeves with a common diameter).

- Transition fitting (for joining sleeves of different sections).

- Swivel element.

Typology of connections:

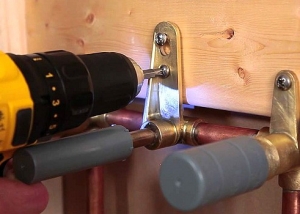

- welding method (joining with a metal pipe on a thread on the reverse side);

- threaded method (internal or external along the edges of the part);

- clamping method (the nozzle is supposed to have a specially treated surface for greater tightness).

Our fittings are widely used in plumbing and gas industry - when connecting taps and valves, branches, hoses and installing pressure gauges. Through them, a connection to equipment of different functionalities is made. The thread on the nozzle may be missing or on one side.

This item is produced from different materials:

- stainless steel;

- brass;

- LDPE, PVC and other polymers.

The “fitting” polymer part is suitable for joining flexible types of pipelines, watering hoses and connecting high-pressure braided pipes used for gas equipment.

Reliability of articulation using a fitting for a high pressure hose affects the life of the pipeline. Fast and high-quality installation depends on how correctly the variety of the connecting module is selected.

From several solutions for extension and branching of hoses or pipes, choose the appropriate type of this connecting element and the most rational method of fastening. In many cases, only the nipple joint enables effective and high-quality coupling of communication areas, ensuring long-term and flawless operation.