To connect profile pipes, suitable fasteners are required, the number of types of which in the modern market is quite large. The finished design can be mobile or stationary. In the first case, the crab systems for profile pipes are considered the most effective. Such fasteners appeared on the market not so long ago, but very quickly gained relevance and popularity.

Content

Characterization and application of the crab system

Crab fasteners for profile pipes are widely used to create small-sized metal frame structures. They allow you to work with both square and rectangular products, as well as transform or mount any building from pipes according to your own design. The crab attachment system is considered universal, durable, very easy to use and affordable.

To install such elements, welding is not required, which requires the presence of specialized skills and specific equipment. Such a fastening for a profile pipe provides a strong and reliable connection, which is almost no worse than a welded one.

Crab systems are used to create:

- tent structures, peaks, canopies, transformers (summer cafes, exhibition halls, restaurants), arbors, car canopies;

- constructions for beach showers, locker rooms, fences, terraces, shelving, scaffolding, animal enclosures;

- winter gardens, lawn fences, vineyards, trade displays, greenhouses, modular partitions, etc.

When using crab systems, there is no need to erect a new structure, it is enough just to dismantle the old unnecessary structure and move it to another place, or build another one.

The main types of fastening

Crab fasteners for profile pipes are available in the form of special clamps, which are:

- T-shaped;

- L-shaped;

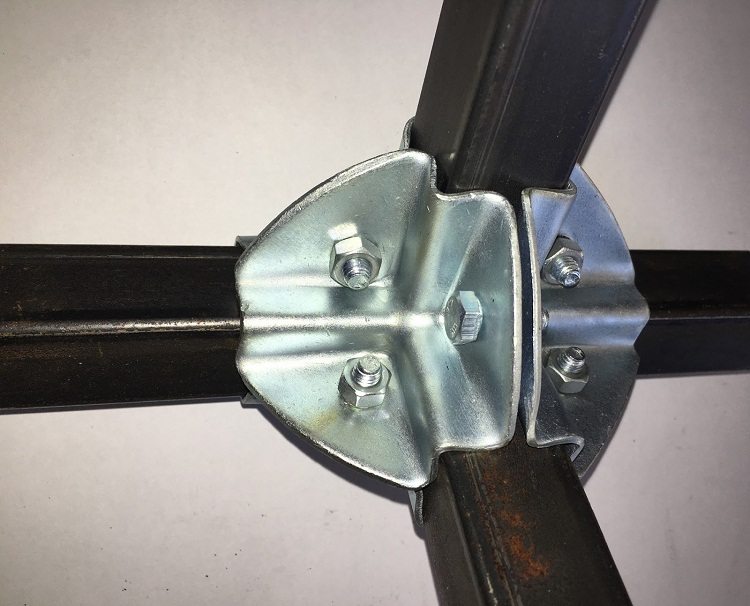

- X-shaped.

Each mount is able to connect a certain number of profile products and has its own installation location. The T-shaped system is designed to combine the three pipes used in pipelines with a small diameter, to greatly simplify the entire installation. L-shaped mount reliably connects two pipes in the corners of the created structures. Using the X-shaped fastener, you can effectively fasten 4 elements that are located in the middle of the structure being created.

Approximate product characteristics are given in the table.

Table 1

| Characteristic | unit of measurement | View of the crab system | ||

| T | G | X | ||

| Galvanized metal thickness | Mm | 1,2 | 1,2 | 1,2 |

| Shelf | Mm | 20 | 20 | 20 |

| Holes | Mm | 6,5 | 6,5 | 6,5 |

| Length | Mm | 55 | 55 | 92 |

| Width | Mm | 92 | 55 | 92 |

| Half weight | G | 45 | 30 | 70 |

Mounts are made of powder-coated or galvanized metal 1.5 mm thick.

Note! Uncoated and oxidized elements are also found.

Structurally, the system consists of two halves that are connected by nuts and bolts. The most popular is the size of products 95x65 or 95x95 mm.

Benefits of Crabs for a Profile Pipe

The crab pipe system has a number of advantages, including:

- the possibility of reusable and safe for the construction of mounting / dismantling;

- no need to call a welder or other specialist - the connection can be done independently;

- for dismantling the metal structure from the profile pipe, an additional tool is not required except an adjustable wrench;

- wide scope;

- load distribution throughout the frame;

- low cost of the resulting structures;

- providing additional strength and rigidity of the structure.

To perform the connection of profile products, the presence of such elements is required:

- wrenches of various diameters;

- directly crab for pipes with all the necessary details;

- bolts and nuts with M-8 thread, if you plan to work with a large number of profile products.

A similar fastening system for the pipe also has good durability.

Some disadvantages of the elements

Of the shortcomings of the crab fasteners emit:

- the ability to dock pipes only small sizes;

- docking exclusively at right angles;

- risk of tearing;

- the need for ongoing diagnosis;

- the possibility of violating the geometry of the frame;

- susceptibility to corrosion (if the appropriate treatment is not carried out).

In most cases, fasteners are suitable for pipes with a cross section of 20 × 20, 20x30, 40 × 40, 20x40 millimeters. Fixation of the connecting sticks takes place by the clamping method with the bolts being tightened not on the screed itself, but on the system. For this reason, the structure (for example, greenhouses) becomes weak at break. In some cases, the pipe can be easily pulled out of the fasteners without much difficulty.

Note! If the structure is located outside the premises, then it is constantly affected by wind, snow or temperature loads. Over time, the system may become loose, so periodic fastening of fasteners is necessary. If you do not keep track of this moment, then the design is able to skew and break accordingly.

With insufficient treatment of metal elements with an anti-corrosion composition, the pipe inside the fastener will quickly rust, since condensation and precipitation can accumulate in the crab fasteners.

The crab pipe fastening system is considered one of the most acceptable and reliable elements for creating convenient and mobile metal structures with your own hands. To work with them do not require special skills.