Profile pipe farms are widespread in the household and industrial sectors. On the basis of such a frame, you can build any structure: from a residential building to a hangar, a warehouse or even a stadium. The types and sizes of such metal structures are very diverse: trusses can even serve as a frame for chimneys. The basis of any building will be a drawing, so special attention should be paid to the correctness of its preparation.

Content

- 1 The list of types of farms from a profile pipe

- 2 Calculation of a truss from a steel profile pipe

- 3 Calculation of an arch truss from a profile pipe

- 4 Requirements for the calculation of the profile pipe for the construction of the farm

- 5 Recommendation for the calculation of a metal truss from a profile pipe

The list of types of farms from a profile pipe

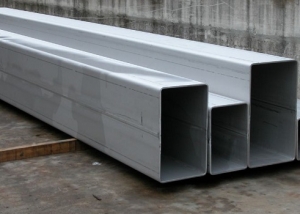

Metal trusses from a profile pipe for a canopy are constructed from a profile, most often steel. A profile can have various section shapes: oval, square, and the most popular - rectangular.

Types of farms have divisions into two categories: farms, where all the elements are mounted together in the same plane and structures with a suspended structure (includes the upper and lower zones).

Structures are divided according to the following characteristics: the necessary load on the profile, the slope of the system, the type of location of the floors, the span and degree of inclination. Depending on these factors, farms can be as follows:

1. Structures with a slope of 22-30 degrees. The stability requirements for farms of this kind say that their height should not exceed 1/5 of the entire length. Typically, the calculation of the height is carried out precisely according to this principle, dividing the planned length of the hangar by 5. Such a slope is chosen when they want to achieve the relative ease of the system.

If the length of the entire structure exceeds 14 meters, then the braces should be placed in the direction from top to bottom. At the same time, a panel with a length of 150-250 cm is placed on the upper tier. Ultimately, a structure with two belts is obtained, the number of panels will also be even.

The shape of the farms and their number depends on the type and size of the structure, as well as on the estimated load on its roof

Helpful advice! If you plan to build a farm with a span of more than 20 meters, you need to install truss elements, which will be supported by additional columns.

Another frequently used variety of this type will be the so-called Polonso trusses - triangular structures with a connection in the form of a puff. A truss from a Polonso profile pipe is considered very lightweight, since during its construction it is possible to avoid too long braces.

2. Farms with a nominal slope of the roof in the limit of 15-22 degrees. This option is considered for structures that will not eventually have a span of more than 20 meters. Types of farms with such a bias have a height of 1/7 of the total length. If it is necessary to increase the height, the lower belt should be composed of broken segments.

3. Designs with the smallest slope not exceeding 15 degrees. With a planned truss angle of up to 15 degrees, trapezoidal designs are the best option. The calculation of the height is carried out for individual reasons, it all depends on the specific angle of the roof and the purpose of the hangar. The height can be in the range from 1/7 to 1/12 of the length.

For trapezoidal trusses, the optimal length of metal panels should be 1.5-2.5 m. If the drawing does not include a suspended ceiling, the braces can be replaced by a triangular lattice.

When it comes to the shape of the structure, trusses from a profile pipe are of the following type:

- single slope;

- gable;

- direct;

- arched.

The last variety - arched type trusses - are the most common. They are strong enough, they can be sheathed with polycarbonate sheets. The calculation of the canopy of the arch structure must be very accurate so that the weight is distributed evenly over the profile. Arched trusses are built from ordinary profile pipes, and from welded together.

Calculation of a truss from a steel profile pipe

The mechanism for calculating and creating a farm drawing from a profile pipe is carried out in several important stages:

- The initial stage is the calculation of the length of the hangar (garage, barn - premises, the construction of which is planned). The height of the metal structure will depend on this indicator. In turn, the length of the structure directly depends on the angle of the roof.

- Next, the contours of the profile belts are selected. The choice will be affected by the type of purpose of the hangar, the type of roof overlap and the angle of its inclination.

- Now that all the dimensions of the metal structure are known, it should be decided whether it will be possible to transport the farm to the object if the construction is carried out at the construction site.

- It is necessary to provide for the presence of a building lifting of the roof if the length of the hangar is in the range of 12-36 m.

- Calculate the dimensions of the panels. The calculation is based on an indicator of loads constantly or periodically affecting the structure. If the truss is triangular in shape, the nominal angle of inclination will be 45 degrees.

- The distances between all nodes are determined, a farm drawing is made of a profile pipe based on the measurements and calculations.

Helpful advice! For more accurate calculations of the construction of an arch hangar from a profile pipe, it is recommended to use a construction calculator. In general, carrying out such calculations manually now is a rarity, claiming accuracy of calculations can be obtained using special programs for architects and builders on a PC.

Calculation of an arch truss from a profile pipe

Consider a specific calculation example for an arched canopy. The parameters of the proposed structure will be as follows: the farms are located in increments of 1.05 m, the loads will be concentrated in the nodal areas. The height of the arch in our case should not exceed 3 meters. The recommended truss height will be 1.5 m - this parameter is considered more attractive both from an aesthetic point of view and for reasons of strength. Between the supports, a span of 6 m (L) is taken, an arrow of the lower level is 1.3 m (f). The circle in the lower tier will have a radius of 4.1 m (r). The angle between the radii will be α = 105.9776 °.

The length of the profile from the lower zone is calculated by the formula:

mn = π * Ra / 180.

In it: mn is the profile value of the lower zone; R is the radius of the circle; A is the angle between the radii; π is a constant.

Eventually:

mn = 3.14 x 4.1 x 106/180 = 7.58 (m).

The step between the nodes of the structure in the sections of the lower zone should be 55.1 cm, while the steps between the extreme sections are calculated individually. To simplify installation, the indicator can be rounded to 55 cm, but you should not increase the step.

The calculation of the canopy of small dimensions allows the number of spans in the region of 8-16. For the minimum number, the length of the rods will be 95.1 cm with a step between the belts in the region of 87-90 cm. For the maximum number of spans, the step will be 40-45 cm.

Requirements for the calculation of the profile pipe for the construction of the farm

When choosing products of profile hire, especially for large-sized canopies, it is worth following the data provided by SNiP:

- 07-85 - data on the interaction of snow loads and the weight of the remaining structural parts of the structure;

- P-23-81 - algorithm for working with profiled steel products.

The wall canopy also carries loads, and its design also needs to be done taking into account the snow cover in winter

The data from the presented provisions will help you quickly navigate in choosing the type of truss, the angle of the roof and the section, the size of the profile pipe for the racks of the building.

Important! The choice will also be the location of the region, the amount of precipitation during the winter period.

Consider the following example: it is planned to build a wall canopy with dimensions of 4.7x9 meters. Its front edge rests on the racks, and the back is attached to the outer wall of the house. The construction will be erected in the southern region, for example, in the Krasnodar Territory. Information on the snow load for each region can be found on the Internet, in our case it will be 84 kg / m2. The optimal angle of inclination of the roof for a canopy of this size will be only 8 degrees.

One stand 2.2 meters high has a weight of 150 kg, and its vertical load will approach 1.1 tons. Profile pipes of round (oval) cross section for these purposes will not work, the minimum indicators for profile square pipe - cross section 45 mm and wall thickness 4 mm. But if you slightly upgrade the design by introducing two parallel belts with an oblique grating into it, you can take a profile with a cross section of 25 mm and a wall thickness of 3 mm for them. With a truss height of 40 cm from the profile pipe, square profiled pipes with indicators of 35 mm and 4 mm, respectively, should be used for belts.

For simplicity of calculating the truss from a profile pipe for a canopy, you can use the table of correspondence of the section and wall thicknesses from GOST 30245.

Table 1

| Lock about fil straight ug. sections |

Lock about fil quadr. sections |

Wall thickness indicators | |||||||||||||||||

| 1 | 1,5 | 1,8 | 2 | 2,5 | 3 | 3,5 | 4 | 5 | 5,5 | 7 | 8 | 9 | 10 | 12 | 12,5 | 14 | 16 | ||

| — | 15 | + | |||||||||||||||||

| — | 20 | + | + | + | |||||||||||||||

| 40x20 | 25 30 |

+ | + | ||||||||||||||||

| 40x25 | — | + | + | + | |||||||||||||||

| 60x30 and 60x40 | 40 50 |

+ | + | + | + | ||||||||||||||

| 80x40 | — | + | + | + | |||||||||||||||

| — | 60 | + | + | + | + | + | + | + | |||||||||||

| — | 80 | + | + | + | + | + | |||||||||||||

| 120x80 | 90 | + | + | + | + | + | + | ||||||||||||

| 140x120 150x100 | 100 120 |

+ | + | + | + | + | + | + | + | ||||||||||

| 160x140 180x120 180x140 240x120 | 140 150 160 180 |

+ | + | + | + | + | + | + | |||||||||||

| 150x130, 160x120, 180x100 | — | + | + | + | + | + | + | + | + | ||||||||||

| 240x150 250x140 | 200 220 |

+ | + | + | + | + | + | ||||||||||||

| 300x100 | — | + | + | + | + | + | + | + | + | + | + | ||||||||

| 260x240 300x200 | 250 300 |

+ | + | + | + | + | + | + | + | ||||||||||

So that the structure does not collapse under the influence of corrosion, for its foundation, it is necessary to choose pipes made of alloy steel

Metal pipes for the construction of an arch canopy should be purchased high quality, preferably from alloy steel. The alloy must have a large amount of carbon - this creates sufficient protection for the metal from the effects of natural factors and the environment.

Recommendation for the calculation of a metal truss from a profile pipe

There are some subtleties in farm design:

- To forcefully lighten the weight of the structure, it is possible to build a hangar with additional gratings (in that case, there is a minimum roof slope);

- to facilitate the roof with a medium slope, broken lower belts are used;

- the distance between the individual farms does not exceed 175 cm.

When manufacturing and welding metal trusses from a profile pipe, the following rules should be followed:

- The connection of the elements of the hangar is carried out using tacks and twin corners.

- Details of the lower belt are welded by equilateral corners.

- The truss frame in the upper zones is connected by I-beams. Their sides should have different lengths, and the joint is made on the smaller side.

- To distribute the loads, channel channels of the paired type and patch plates welded together are used. This joining method is used if necessary to increase the length of the canopy.

- During the work, the quality of each weld is strictly controlled. At the end of the welding process, each seam should be cleaned.

- If necessary, the canopy can be painted with anti-corrosion paint. Alloy steels do not require additional painting.

Trusses from a profile pipe are the optimal basis for household and commercial purposes.Calculation of the hangar is time-consuming, it must be done by a specialist, only in this case it is possible to obtain a reliable scheme of the future design.