Sleeves (hoses) are used for pumping liquids, mixtures and solid materials (cement, fertilizers, sand). They are used both on stationary objects (in industrial premises, sewer and drainage systems, pumps and pumps), and on mobile, moving technical means. They are distinguished by elasticity, resistance to damage, ease of use.

Suction hoses are universal products used in systems for drainage, supply and pumping of various liquids, fire fighting

Content

Sleeve Properties

The rubber suction sleeve has a relatively rigid structure, provided by the presence of a frame, in most cases a textile one. Find application in cases where it is necessary to ensure the supply of fluid directly from the source. Given that the base of such a hose is made of textile, it is not recommended that the sleeve comes in contact with hard surfaces. This will avoid unwanted mechanical damage that can significantly reduce the life of the product.

Suction hoses made of polymer materials are becoming increasingly common. Polyvinyl chloride (PVC) hoses are valued for their lightness, sufficient strength and ease of use and storage.

In the production of pressure hoses, a technological process is used that allows you to achieve a combination of two qualities that are most important for these products:

- flexibility;

- durability.

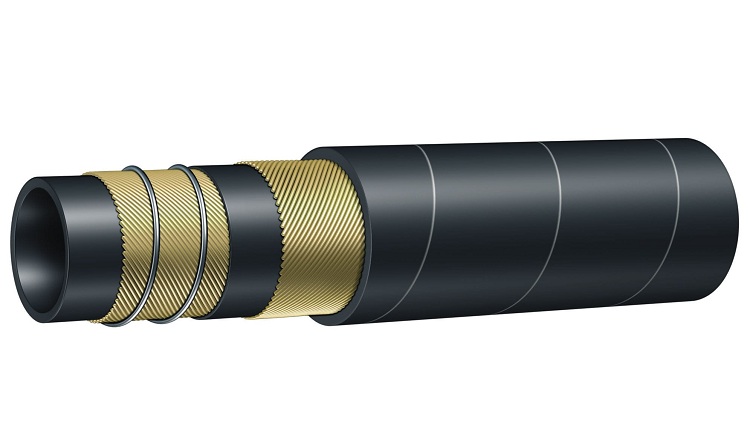

High pressure hoses are pumped through pressure hoses to provide powerful discharge head. The frame is composed of synthetic yarns, and the outer shell is formed from high strength vulcanized rubber.

Such products are distinguished by a multilayer structure, which gives them special strength and flexibility.

Good to know! Pressure-suction hoses combine the properties of suction and pressure hoses. Thanks to this, they found application in various fields of human activity.

Sleeves technical pressure head soaking up: classification

The production of pressure-suction hoses is regulated by GOST 1976 (5398-76). They are made on a textile frame, reinforced with a metal spiral (corrugation) along the entire length of the hose. At the ends of the corrugated pressure-suction hoses, soft cuffs are installed, allowing connection to the valve. These hoses are made smooth or corrugated. Their length does not exceed 10 m.

Based on a parameter such as operating pressure, the pressure-suction hoses are divided into two groups:

- I - with a working vacuum of 0.08 MPa;

- II - designed for a working pressure of 0.3 MPa or 0.5 MPa, or 1 MPa.

Another basis for the classification is the working environment, for the transportation of which the pressure-suction hoses of the following classes are intended:

- automobile and aviation gasolines, kerosene, fuel, including diesel and for jet engines, fuel oil, oil-based oils - B;

- process water - B;

- nitrogen, air, carbon dioxide, inert gases - G;

- inorganic acid solutions, alkali solutions, the concentration of which does not reach 20% - KSh;

- drinking water, food (alcoholic drinks, alcohol, milk, slightly acidic solutions of substances of organic and inorganic origin) - P.

Hoses of all classes belonging to group I are able to maintain tightness at a hydraulic pressure level of 2 atm (with an internal diameter of more than 75 mm) or 3 atm (with an internal diameter of up to 75 mm). Sleeves of class G are produced with a five-fold safety factor (5P), for products of classes B, V, KShch and P, a three-fold safety factor (3P) is provided.

Corrugated hoses are also marked depending on the temperature and climatic conditions of use. Marking U (intended for use in a temperate climate) is applied to products that remain operational at temperatures ranging from -35º С to + 90º С. -50º C to + 70º C. Marking T (application in the tropics) implies the performance of the product when the temperature drops to - 10º C.

The production of MBS pressure-suction hoses (oil and petrol resistant) is regulated by TU 38 105373-91. Unlike others, these products are endowed with the property not to accumulate static electricity. This feature allows the use on vehicles designed for the transport of various flammable liquids. (The marking indicating the working environment is Ba, i.e., oil and petrol resistant antistatic).

Design features of pressure head suction hoses

The suction and pressure hose is designed so that it can withstand the effects of excess pressure and vacuum. Strength characteristics are provided by a steel wire spiral (corrugation) and a textile frame of two inner layers and one outer layer. Elasticity and tightness are set by the intermediate rubber layer and the inner rubber chamber.

Depending on the design and purpose, the sleeve may have different types of connecting elements for connecting to the source of the working environment

The corrugation extends along the entire sleeve, excluding the soft cuffs located at the ends with a length of 120 mm or 160 mm, depending on the diameter. Cuffs are used to bring (tightening the sleeve) to the connecting suction heads. They are fixed with galvanized wire or clamps. It is on the cuffs that a marking is applied containing data on:

- name of the manufacturer;

- a group;

- standard number;

- length

- working pressure;

- production date.

An important element of the pressure head suction hoses is the suction net. It is intended so that when using a hose to collect water from an open reservoir, it does not happen:

- hit of random objects in a sleeve;

- spontaneous emptying of the product.

The design of the suction grid includes:

- housing;

- fitting fastening to the connecting head of the sleeve;

- check valve;

- special lever that opens the valve;

- filter grate.

The mechanism of action of the suction mesh is as follows. When creating a vacuum (vacuum), the next time you turn on the pump (pump) inside the pressure-suction hose, the check valve opens under the pressure of water filling the sleeve and cavity of the pump (pump). Turning off the pump will open the check valve and keep the entire line in a state filled with water.

Water intake (for example, for fire fighting) with the help of a sleeve can be made both from a special hydrant and from any open reservoir

Important! When the need for water injection from an open reservoir disappears, the pressure-suction hose must be removed. Then use the attached rope, with which, turning the lever, open the check valve.Water flows out, releasing the sleeve.

The use of rubber suction hoses

Elastic rubber pressure-suction hoses are used where flexible piping is required. When completing fire fighting equipment and special-purpose vehicles, they use two types of rubber hoses:

Suction. They are needed to take water from open reservoirs and to carry out the reverse operation - discharge. They are also used as a flexible insert during the operation of dredging (sludge) shells, when the dredging mechanism is immersed or lifted. The operation of the suction pipelines (hoses) occurs under vacuum, so their design is provided with radial stiffness and stability. Reach the required performance by reinforcing hoses. Steel or galvanized wire used for reinforcement turns into the main structural element. It has a load, it is designed to prevent, as much as possible, wrinkling of the hose.

Pressure-suction. They are in demand for supplying water for fire fighting equipment. Suction fire hoses can supply water both from an open reservoir and from a hydrant, under pressure. In addition to fire fighting equipment, pressure-suction hoses are equipped with special-purpose vehicles. These are tankers that transport various liquids or mixtures, such as fuel trucks, water carriers, milk tankers, cement trucks, etc. It is impossible without pressure-suction hoses to use various municipal equipment: sewage (vacuum), sludge and canal washing machines.

Rules for the operation and storage of pressure-suction hoses

Hoses can be used for their intended purpose long enough if you take as a rule certain measures during operation and storage:

- avoid contact of products with acids, alkalis and oil products (if they are not intended for the transportation of these working fluids);

- avoid laying sleeves at steep angles. If it is impossible to avoid this, you should use an unloading rope;

- if necessary, use cushioning tapes;

- Do not drag on a hard surface and do not drop onto a hard surface. This will prevent leakage due to mechanical damage, tears and cracks;

- when laying (building up) the line for the intake (supply) of liquids, avoid ingress of solid particles (soil, sand, etc.) into the joints. Preserving the tightness, it will be possible to prevent a partial or complete pressure drop in the system;

- when taking water in the winter, you should take care to maintain a constant circulation so that the liquid does not freeze inside the hoses;

- sleeves used in the cold should be thawed (and in case of contamination - soaked) and washed;

- washed sleeves should be dried outdoors (in the warmer months) or in a dryer. When drying in the open air, direct exposure to sunlight should be avoided, since ultraviolet radiation negatively affects the hose material.

Repair of the pressure head soaking-up sleeves

Even with the most careful use of any design, damage cannot be avoided. Observing the rules of operation and storage of hoses, you should pay attention to emerging defects: abrasions, cracks, punctures, etc.

When examining, do not limit yourself to just checking the condition of the outer side of the sleeves. It is also important to pay attention in time to the emerging detachment on the inside. Eliminating the effects of external damage, leakage, two methods are used:

- Vulcanization using crude rubber.

- Applying patches on the outside of the surface with adhesives.

If damage to the connecting suction heads is detected, they are replaced. New connection heads are secured with galvanized wire or clamps.

Important! Repaired products should be tested before operation.

Externally unpretentious suction hoses play a very prominent role in economic activity and life. They are familiar, trivial like any element of everyday life, almost never attract idle attention. Unless something extraordinary happens that disrupts the usual course of events (fire, gust of sewage, dredging in a pond that has not been cleaned for a long time). At the same time, they relate to those things without which the normal life activity of modern society seems unimaginable.