A piping network for any purpose is a serious engineering design in which each part carries a certain functional load, is responsible for the quality, safety, and uninterrupted operation of the network. But the highway does not consist of pipes alone, reinforcement is also needed. The structural solution of such parts in complexity, manufacturing material (steel, cast iron, brass, plastic), types and purpose are diverse. It is used for steel, metal-plastic, polyethylene, polypropylene systems. A wide range of these products is classified, which helps to understand the understanding of the issue of pipe fittings: what is it?

Content

Classification of pipe fittings

What is “pipe fittings”? This is a mechanism whose work consists in changing the cross-section of the conducting lumen of the pipeline with the aim of organizing the movement (adjustment, shutdown, mixing, discharge, distribution) of one or more flows of liquid, gaseous, powdery substances, according to the technical parameters of pressure, temperature, power, direction, and physic -chemical state of the working environment. The classification is quite extensive, such elements are divided according to different criteria.

1. According to the functions performed:

- locking - hermetically blocks the movement of matter in the line at the time of closure, also provides patency without resistance when opening the mechanism (valve, valve, shutter, gate valve). The need for this process arises periodically according to technical requirements. Closing element refers to the descent of the working medium from the tank or entering the instrumentation;

- Regulating - allows you to change the parameters of temperature, pressure, pressure, level, flow rate of the transported substance (valve, self-acting valve, steam trap, level regulator). Reducing or throttling valves of pipelines regulate pressure by means of hydraulic resistance;

- safety - automatically triggers to open the valve at a pressure exceeding the norm, during which the excess of conducted mass is discharged (safety valve, membrane fuse, bypass valve);

- protective - shuts down the equipment, the pipeline section during an emergency change in the parameters of the conducted substance or blocks the reverse current of the working medium, protecting the pipeline and equipment from emergency situations (non-return valve, pneumatic valves, shut-off valve);

- phase separation - it separates the conductive medium in different phases of the state (condensate removal, oil / gas / air separation);

- distribution and mixing - distributes the flow of substances in predetermined directions, or mixes the flows into a single (distribution tap / valve, mixer, three-way valves);

- control - determines the level, the movement of the conducted mass (level sensor, stopcock).

2. According to the control method:

- controlled - is driven by manual manipulation or by means of a mechanical (pneumatic, hydraulic, electric, electromagnetic) drive. Remote control can be carried out separately by a drive installed from the pipe fittings, connected by bearings, shafts, cable, gears. Most of the products, designed for pipes of Ø no more than 400 mm, are controlled by a manual drive, the process is slow and requires considerable effort.;

- automatic - it acts autonomously under the influence of the working environment or with the help of automatic triggers.

3. According to the method of connection to the pipeline:

- coupling - coupling with a thread inside, applicable to Ø no more than 80 mm and working pressure 10 atm, suitable for metal-plastic, polyethylene, polypropylene pipelines;

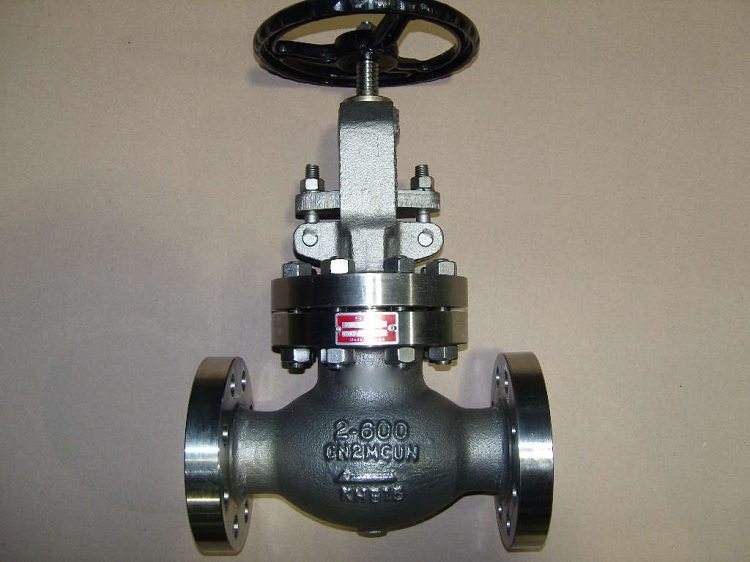

- flanged - a strong connection with a bolt coupler, flanged docking can be repeatedly disassembled and assembled for repair, cleaning of fittings. Periodic monitoring of the fasteners is necessary, as they can weaken;

- for welding - the parts are joined by a weld in the socket or butt, it is considered the most reliable and tight, it is used for the conductivity of hazardous substances. The connection can be supplemented with a washer ring to prevent misalignment of the parts, this method is used when laying pipelines for nuclear power plants;

- pinhole - a method of connecting small-sized elements operating under high pressure (instrumentation and automation) by means of connecting pipes with an external thread and a shoulder;

- nipple - used for fittings Ø not more than 15 mm in laboratory pipelines. The connection is threaded.

Flange connection refers to collapsible fasteners; fittings installed using this method are easy to maintain and replace

4. According to the method of sealing:

- stuffing box - achieved by sealing the contact of the rod and spindle with stuffing box packing (cords of asbestos or hemp fibers, impregnated with a sealing compound, PTFE packing);

- membrane - sealing due to the membrane (elastic elastic disk), which is clamped between the cover and the valve body;

- bellows - moving elements are sealed with a bellows assembly (corrugated tube);

- hose - an elastic hose is included in the valve design, which is pinched, hermetically cutting off the flow.

5. By area of application:

- special - made to order with certain requirements for specific tasks. Pipe fittings of this design are used in laboratory research, testing, defense, nuclear power plants;

- general purpose - serial production products that are widely used in industry, housing and communal services (plumbing, heating), and other manufacturing sectors. These include:

- steam and water - it is widely used in all areas where the pipeline works with water, designed for a different range of diameters and working pressure;

- gas - applicable to gas supply pipelines with requirements for a flammable, explosive atmosphere. Differs in strong, tight connection;

- oil - armature, steady against an aggressive environment, installed on the pipeline with an oil stream or oil products;

- chemical - is developed from oxidation-resistant materials for pipelines of the chemical industry with a very aggressive working environment;

- energy - a type of pipe fittings associated with the operation of power boilers, installations, turbines with high pressure (more than 300 atm) and steam temperature (more than 500aboutWITH);

- ship - is used in the Navy, shipbuilding, offshore structures in conditions of work with an unstable situation and severe marine climate

- reservoir - mounted on containers for dumping the filling medium (drainage fittings), has one connecting pipe.

10. By the type of movement of the working mechanism, these types of pipe fittings are distinguished:

- crane - a locking element having a body of revolution, moves, rotating around its axis with an arbitrary location relative to the direction of flow;

- gate valve - an element of adjustment or constipation moves perpendicular to the direction of flow, has extreme open positions. and close .;

- shutter (shutter, tight valve) - the disk-shaped shutter element rotates around its axis perpendicular or at an angle relative to the flow;

- valve (shut-off valve) - the locking and adjustment body is mounted on the spindle, moves parallel to the flow reciprocatingly, overlapping the cross section in the horizontal plane. It works with gaseous and liquid media, sometimes valve and ball.

7. Conditional pressure:

- vacuum - isolates part or all of the vacuum chamber from the pumping system to control the sequence of the pumping process;

- absolute pressure (up to 0.1 MPa) - applicable in equipment for measuring the absolute pressure of the pipeline environment;

- low pressure (up to 1.6 MPa) - household metal-plastic, polyethylene, polypropylene water pipes and steel systems;

- medium pressure (up to 10 MPa):

- high pressure (up to 100 MPa);

- ultra-high pressure (more than 100 MPa).

8. According to the working temperature:

- cryogenic (-150aboutC and below);

- refrigeration equipment (from -60aboutC to -150aboutWITH);

- low temperature (from -20aboutFrom to -60aboutWITH);

- medium temperature (up to 400aboutWITH);

- high temperature (up to 600aboutWITH);

- heat resistant (600aboutC and above).

Flanged fittings

Flanges complementing the reinforcing structure are fastening elements in the form of metal flat rings or disks with perimeter holes. Through holes, threaded bolts or studs are tightened, providing a reliable connection. Flanged fittings are a combination of different types of pipeline products with this type of connection, it is common in installations operating with a wide range of pressure and temperature.

The ability to disassemble the mount allows you to audit or repair valves and pipelines. The design, dimensions, requirements of reinforcing flanges comply with GOST. As part of the reinforcing body, the flanges are cast from cast iron (gray, malleable) or steel. A similar flange is welded to the pipes.

The limiting parameters of operation of fittings made of cast iron and steel of internal networks are given in table No. 1.

Table 1

| Limit value Ø, mm | Material | Working pressure, atm | Working temperature, aboutWITH |

| 200,0 | Gray cast iron | 2,4; 12,5 | Any; 300 |

| 300,0 | Gray cast iron | 7,8 | 300 |

| 400,0 | Gray cast iron | 12,5 | 200 |

| 500,0 | Gray cast iron | 4,8; 12,5 | 300; 150 |

| 600,0 | Gray cast iron | 7,8 | 150 |

| 80,0 | Malleable cast iron | 38,7 | 400 |

| 100,0 | Malleable cast iron | 24,2 | 300 |

| any | Steel | 62,0 | 450 |

Important! Installation of malleable iron fittings on an overhead installation pipeline is not permissible at a temperature of -30aboutC, and from gray cast iron -10aboutC, it is replaced by steel.

Flange fittings are used for pipes with a diameter of 50 mm and have impressive dimensions and weight. She is not afraid of pressure drops, the temperature of the working medium can reach 400aboutC, any position in space is suitable.

Pipeline fittings

During the installation of the pipeline, it becomes necessary to connect pipes of different materials (steel, metal-plastic, polyethylene, polypropylene) and diameter values between each other or a flange element must be built into the network at a site of special importance where an emergency is possible.In this case, connecting fittings are used - auxiliary parts of the docking (flange adapters, clamps, couplings, plugs, bends, crosspieces, tees) that do not have a shut-off-control mechanism in their design.

Steel connectors are suitable for all types of pipelines, as they are durable and able to withstand high loads

Such fittings allow quick, robust installation, replacement of parts, inspection and repair of the pipeline. The connection method is selected for each type of pipe as intended. Docking for metal-plastic pipes is preferable crimp, and for polypropylene pipes - welded. The joint is solid, tight, durable. The diameter of the connecting fittings varies from 25 to 2020 mm, the nominal pressure from 1 MPa to 4 MPand. Production material: cast iron, steel, plastic. Type of connection - threaded, flange, crimp.

Stainless steel pipe fittings are especially durable, resistant to aggressive environments, corrosion, temperature, wear, and therefore indispensable in the chemical, oil and gas, food, pharmaceutical industries, as well as nuclear power plants.

Stainless Pipe Fittings

The use of stainless steel made it possible to obtain a qualitatively different type of products that do not interact with the working environment (without changing its properties). In the food industry, such pipeline parts are indispensable; they are environmentally friendly, chemically inert, and stable in all respects.

High stainless steel fittings (flanged, connecting, taps, gates, valves, steam traps) are included in the stainless pipeline transporting drinking water, milk products, oils, alcohol with the possibility of cleaning the system after the production cycle. In the brewing and wine industries, stainless parts make up systems with temperature, pressure, distribution, and mixing controls.

Of course, stainless parts are applicable to domestic and industrial water supply systems, heating.

Stainless steel fittings suitable for use in the food industry, domestic plumbing and heating systems

Pipe fittings for nuclear power plants

The operation of a nuclear power plant (NPP) is a complex energy production of increased danger. All equipment should work exactly “like a clock”, the pipeline network is no exception. It contains a large number of fittings, units, instrumentation.

Requirements for installing pipe fittings at nuclear power plants:

- the movement of the working medium must correspond to the directional arrow on the body of the part;

- it is forbidden to use fittings for other purposes (shutoff as regulating);

- all types of parts should have free access;

- high temperature fittings should be closed by a removable, collapsible design with thermal insulation.

The connection of the parts of the system with medium and high pressure is welded (the ends of the fittings for nuclear power plants are welded) or flanged with the least risk of leaks. Production material - high-quality steel, resistant to aggressive environment, loads, wear.

Safety and protective fittings play an important role. In order to prevent overpressure and an emergency, two safety valves (pulse, lever, spring) are installed on the steam generators of the dual-circuit nuclear power plants - the main and auxiliary ones. Mandatory discharge of steam into the bubbler. Drainage from the NPP circuits is carried out by two valves installed in series: first, shut-off, then regulating. Locking opens completely. The number and installation locations of fittings are clearly calculated, and a sophisticated sealing system is used in areas of high radioactivity. After repair, valves for nuclear power plants undergo a series of pressure tests with a 25% excess of the working one.

Reinforcement for plastic pipes

Auxiliary parts for metal-plastic pipelines of internal laying are used to control the flow of water or coolant when distributing pipes to devices of water supply, water heating, heating, drains. These are taps, gates, gates, valves, gate valves, mixers, pressure regulators, check valves, designed to work with medium temperatures up to 95aboutWith and pressure of 16 atm.

The reinforcement of metal-plastic pipelines used in domestic conditions is small in size and aesthetically pleasing, has a threaded and press connection, legend, which greatly simplifies installation. Made of nickel-plated brass, resistant to corrosion. The most commonly used are various types of fittings and ball valves.

ATimportant! It is better to stop the choice of fittings for metal-plastic pipes at a trusted manufacturer, quality products have a long service life.

Fittings for polyethylene pipes

As in metal-plastic pipelines, fittings for polyethylene pipes are used in pressure and pressureless systems. The widest assortment of connectors for clamping, welding or flange connection. The welded connection of polyethylene products is considered the most reliable, tight, makes up a single cast body.

The movement of the medium flow of these pipelines is regulated using polyethylene (PND) or brass taps, valves, dampers, designed for pressures up to 16 atm and a flow temperature of 45 - 80aboutC (hot water), not subject to corrosion. Ball valves, made entirely of polyethylene, can undergo deformation if the temperature is not observed.

Fittings for polypropylene pipes

Shut-off and control pipe fittings, types of connecting fittings for polypropylene pipes are the same as for polyethylene pipes. Designed for pressure up to 20 atm, medium temperature up to 90aboutC. Many manufacturers now produce models of polypropylene elements with a holder made of nickel-plated brass hot pressed, which is a monolithic structure that is resistant to thermal deformation.

The presence of built-in brass threaded collapsible joints in polypropylene fittings allows equipping a plastic pipeline with metal fittings. The cost of polyethylene and polypropylene accessories is much lower than metal counterparts.

Symbols for valves

In order to choose the right fittings for steel, metal-plastic, polyethylene, polypropylene and not only pipelines, the following conventions are used - a summary of the technical parameters of the classification detail of the Central Design Bureau of Central Design (Central Design Bureau of Valve Engineering). The cipher contains a specific sequence of alphanumeric values. Two digits in front are the reinforcement type, followed by one, two letters are the product material, then one, two digits are the serial number of the reinforcement of this type in the catalog, the last two letters are the seal material or the inner surface of the product, the Roman numeral is the product design, Arabic numeral - design of various environments, mode.

Designation example: 15s979nzh - carbon steel shut-off valve with electric actuator, valve number (79) and stainless steel seal.

Also used are schematic (graphic) symbols for the specification and detailed design of the system developed by the Central Design Bureau. Designations constitute a single documentation system, fixed by GOST.

All varieties of pipeline valves are designed for specific operating conditions, they participate in the uninterrupted and safe operation of systems for various purposes in all areas of activity, making them more efficient.