The slide gate is one of the types of control and shutoff valves. This device is usually installed on highways transporting suspended technical mixtures (sewage, sludge), gas and air media, bulk materials. Cope with data streams of types of standard valve is not possible. The reason is that particles of the substance being moved fall between the valve seat and the locking device, preventing the pipe lumen from completely overlapping.

Slide gate valve is a type of shutoff valves, which is characterized by high tightness when working with any type of medium

Content

Gate valve design. Varieties

The main difference between the gate valve from other types of valves is its ability to tightly shut off the pipeline, regardless of the structure of the material. The role of the locking element in this device is played by a flat or wedge-shaped knife. Moving perpendicular to the flow, this accessory gate valve cuts it and ultimately the section is blocked. It is customary to subdivide this type of reinforcement according to the shape of the locking element. In accordance with this criterion, there is a knife gate valve and a wedge-shaped valve.

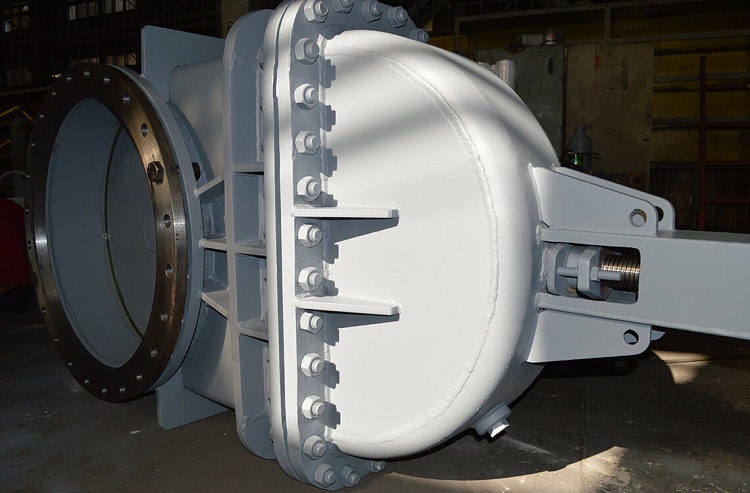

Wedge type device. The wedge gate valve is able to operate at increased pressure of the working medium, due to which it is installed when it is necessary to most reliably shut off the flow. In accordance with the name, its locking element has the shape of a wedge. The same shape is characteristic of saddles with seals. Most often, this device is used as a slide gate valve for sewage.

The locking wedge moves perpendicular to the direction of movement of the working medium under the influence of the force that is created when the spindle rotates. Maximum sealing is ensured by the fact that when the lumen is completely closed, the wedge from the applied force is deformed within the elasticity inherent in the material.

Among the shortcomings of the wedge gate valve device, experts distinguish:

- with intensive use of this device, seals fail quite often;

- the need for a time-consuming procedure for fitting the saddle and wedge in such a slide gate valve;

- if the surface of the wedge is damaged (deep scratches, scratches, corrosion), the sealing will be broken. In addition, such damage can cause jamming of the mechanism;

- when transporting a medium with a high temperature, the wedge of this gate valve expands. This factor makes it impossible to adjust the flow, which can lead to emergency situations.

Knife gate valve. The locking element of such reinforcement is characterized by a relatively small thickness and works like an ordinary knife.

On a note! For this reason, the scope of knife gate valves is practically unlimited, they can be seen on pipelines of any purpose.

Highways are equipped with them:

- mining industry;

- pulp and paper mills;

- oil refining industry;

- sewage and ventilation systems.

It should be especially noted that the knife gate valve can be used even on branches operating during rarefaction. In this case, we are talking about vacuum technology.

Case material and drive types

For the production of shutter gate knife and wedge most often used steel, including stainless steel or cast iron. When choosing a specific modification, consider that a device made of cast iron is more sensitive to the conditions of use. Steel products should be preferred if operation is expected at low temperatures. In addition, a cast-iron slide gate valve does not tolerate impulse loads, that is, it is possible to break its body with a simple blow.

Sliding devices, like other types of valves, are actuated in various ways:

- with the help of a lever or a steering wheel - with a manual drive;

- electric drive;

- hydraulic drive;

- pneumatic drive.

Considered shutoff valves can be mounted on pipelines by various methods. So, on highways along which sludge, drains, oil are transported, most often a flanged slide valve is installed. The differences of this model are the simplicity of mounting / disassembling due to the fastening with bolted detachable joints.

Design features of valves of various types

All considered devices are also subdivided according to the direction of action and the design of the locking working element. The requirements for the level of sealing can be used to interrupt the flow of valves with one or two knives (gates).

The one-knife gate crane is characterized by greater rigidity. It can be installed in pipelines through which the medium is transported under high pressure. Its design is quite simple. The gate moves due to the rotation of the rod, which can be non-extendable or extendable. Thanks to the removal of the kinetic pair of the stem – running nut outside the device’s casing, a tight shut-off of the flow is ensured and the seal glands are prevented from contacting the medium.

Gate valves with two knives seal the pipeline more reliably, but they cost much more and therefore such devices have not been widely used. Users take into account the fact that many cheaper similar devices manufactured by modern industry block the flow no less efficiently.

Helpful information! Often, a double-knife valve with an electric actuator is used as a component of an automated control system on oil trunk pipelines.

If we take the criterion "direction of action" as a basis, the slide valve can be one- or two-sided. Gate valves of the first type are used on branches transporting most known liquids, including aggressive ones, some types of bulk materials, and suspended mixtures. Such a device can be installed on household communications - sewers, water supply, etc.

The installation of a double-sided gate valve is somewhat more complicated. Without going into his description, it will suffice to say that the locking-regulating element of this type is used on special highways. Experts include pipelines designed for such an environment, when changing the direction of movement of which, even in the small range of capabilities of a standard valve, it will not be enough to completely cover the lumen. A double-sided knife gate valve is installed in the gate valves of highways at the enterprises of the food and chemical industries.

Application of knife gate valves with electric drive. Varieties

The scope of the valve with an electric actuator (diameter DN 50) is a water supply system. The electropneumatic slide valve BB32 is mounted in pumps, sewer systems and in mixers. The shut-off electric drive device ДУ100 is widely used in highways transporting drinking water and wastewater treatment systems. Control of the input voltage parameters, as well as the operation of the gate element, is carried out by the control cabinet.

The installation of a slide gate with an electric drive is carried out when it is necessary to realize full automation of the submersible pump. Correct functioning of the valves is ensured by the fact that the control cabinet produces extremely accurate signals.

Rack-and-pinion electric drives, used constantly, also carry out the adjustment of the amount of water consumed. Installation of a remote column on a gate valve with an electric drive provides the ability to control the flow of the working medium.

The model 30s941nzh wedge steel gate valve in fire extinguishing or irrigation systems with high accuracy controls the volume of fluid supply in accordance with the originally set mode. It can also be used in gas transportation systems - steam, gas, oil and oil products. It is allowed to operate a wedge gate valve with an electric actuator in pipelines through which the working medium with a temperature of up to +425 ۫ С.

The conversation about locking elements will be incomplete without mentioning the fact that modern industry also produces a knife gate valve with pneumatic actuator.

Important! The use of compressed gas is indispensable where it is required to completely and reliably exclude contact of the drive mechanism with the transported stream.

According to the criterion of "principle of action" such devices are divided into inkjet and piston. The design of shut-off elements of this type includes a low-inertia jet turbine. Such an implementation of a pneumatic gate valve assumes that this device will perform its functions perfectly due to:

- exclusion of rubbing seals;

- irreversibility of movement;

- smooth running at any pressure of the control gas and at any load;

- fast reverse drive shaft.

The main advantage of a pneumatic shutter is the possibility of remote control.

And in conclusion, it is worth saying that when choosing gate valves, their technical characteristics should be carefully studied. Only then will problems arise with flow control.