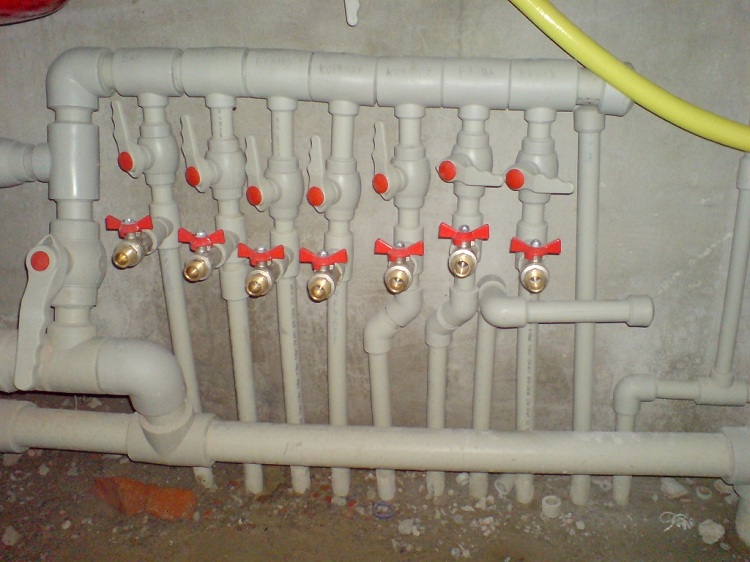

Polypropylene pipelines are very popular in today's market. This is due to the fact that they have a number of undeniable advantages, in comparison with metal counterparts. During the installation of polypropylene communication, you can not do without special fittings - ball valves, which are used to shut off the flow of the working medium in the pipeline.

Content

Features of polypropylene ball valves

Polypropylene ball valve for pipes performs the function of blocking the flow of water in communication. Ball valves are used for the following piping systems:

- cold water supply;

- hot water supply;

- heating communications.

This device is called a ball because its locking element has the shape of a ball. In this ball, as a rule, there is a through hole. Such a ball is made of stainless steel, resistant to the corrosive effects, therefore it can be used in aqueous media.

The ball valve body is made of modern polymeric material - polypropylene. Due to this, the installation of these products is carried out in the same way as the joining of PP pipes to each other. Such a device is characterized in that it has high throughput rates and does not require maintenance.

Another design element of this device is a special lever, through which the position of the locking element is adjusted. To open or close the flow of the working fluid, the ball is rotated with a lever around its axis. This rotation is within 90 ° C.

Polypropylene cranes have many positive qualities that allow you to operate them for a long time without maintenance

Important! Ball valves are not designed to control the flow of the medium. The locking mechanism has two positions: open and closed. If the tap is not fully open or closed, the risk of its rapid wear and breakage increases.

Consider, as an example, the technical specifications of a common ball valve model (PPRC PN20). The operating temperature for such a device is in the range from 0 to +95 ° C. The cross-sectional index of such a device is 20.63 mm, and the service life reaches 50 years (for pipelines transporting cold water) and at least 25 years for hot water pipes. The pressure such a valve can withstand is 20 bar.

Advantages and disadvantages of ball PP valves

Ball PP products are governed by the relevant regulatory documentation, namely, GOST (52134-2003). Like any other product, ball valves have several advantages:

- presentable appearance;

- due to the fact that such products are made of polypropylene, the risk of rust is eliminated;

- resistance to aggressive chemical influences;

- quite a small mass;

- ease of installation.If desired, the installation of the ball valve from the PP can be done with your own hands, however, this requires the presence of special equipment (welding machine);

- affordable cost, since polypropylene is a fairly cheap material;

- long service life (up to 50 years under normal use).

Polypropylene crane is most often a non-separable structure, which in case of breakage will need to be changed

Among the minuses of this product can be identified:

- the inability to adjust the flow rate of the working medium with such a device;

- The ball valve in most cases is a non-separable device. In the event of a breakdown of the ball valve, it cannot be repaired. Defective products must be replaced.

Varieties of ball valves made of PP

First of all, polypropylene ball valves are classified according to their purpose. Such products are used, both in communications that transport cold water, and in hot water supply and heating systems. To begin, consider what ball valves can be, depending on the design:

- collapsible;

- detachable.

Ball-type split polypropylene valves are usually installed in cases where they can be undocked from the system. The connector can be located both on one side of the product, and on both sides.

For the installation of a collapsible ball-type polypropylene valve, special union nuts are used that allow for quick installation of this device. PP folding valves can be of two types:

- direct;

- angular.

Corner products differ from direct ones in that they can be joined with pipes without the use of special transition fittings - couplings. This ability of corner collapsible devices greatly facilitates installation.

Note! Polypropylene ball valves can be used in pipelines not only for economic purposes, but also for technical ones.

Ball valves can have various sizes. The dimensions of these locking devices are selected depending on the specific case. When choosing them, you need to focus on the size of the communication on which they will be installed. The most common sizes of polypropylene ball valves are presented in tables.

Table 1

| Mm | Length mm |

| 50 | 114,5 |

| 40 | 100 |

| 32 | 85 |

| 25 | 71 |

| 20 | 65,5 |

Ball valves can have different colors. It depends on the company that produces them. At the production stage, each such device is necessarily equipped with a marking that can tell about the purpose of the product. For example, the blue strip on the case tells that this device should only be used in communications transporting cold water.

PP ball valve design

Polypropylene ball valve is a type of shutoff valves, which is used mainly in household communications transporting hot and cold water. If you compare the PP taps with brass counterparts, then you can not fail to notice some differences in the constructive plan. In ball valves, there are no internal sealing elements on the stem. Rubber seals in such devices are located outside the cross section of the through hole.

The locking mechanism of such a device itself is equipped with two limiters. These structural elements are rings made of a polymeric material. The main task of these limiters is to fix the node in the right position. The most high-quality models of these products are carried out by means of casting and differ in a monolithic, reliable design.

As mentioned above, the ball, which is located inside such a device, is made in most cases of stainless steel. However, there are models in which this locking element is made of brass. To increase resistance to the harmful effects of corrosion, brass balls are coated with a special anti-corrosion layer of chromium.

Some companies involved in the production of these products may grind the ball at the bottom. This is done in order to save metal raw materials in the production process. Such locking devices are problematic in operation, as they are often clogged.

In addition, the handle of this device can have two options:

- lever arm;

- butterfly.

Cranes are available with different types of handles, you can choose the most convenient depending on the location of the pipes

The lever is fixed on the rod by means of a hexagonal joint and a special rivet.

Tips for choosing a polypropylene ball valve

First of all, before purchasing this product, it is recommended to conduct a thorough inspection. This is a necessary measure, since the surface of the ball valve may contain various deformation signs, which indicates poor-quality products. It is worth paying special attention to how the handle of the crane rotates (rotation should be done with little effort).

Experts do not recommend purchasing ball polypropylene valves in the markets, since there the reject rate is an order of magnitude higher than in specialized stores. Savings in this case are inappropriate, since the acquisition of low-quality products can cost much more after its breakdown.

Helpful information! When buying a ball PP valve, it is also recommended to pay attention to the fact that the internal indicator of the cross-section of the device is the same as the internal diameter of the communication on which the installation will be performed.

Let's look at a few more useful tips that will help you get a high-quality ball valve made of polypropylene:

- It is strongly not recommended to buy used products, as this increases the risk of leakage in communication. In the case of a breakthrough of such a crane, flooding of neighbors from below is almost inevitable;

- It is worth paying attention to the company of the manufacturer. Products from well-known brands are more expensive, but in this case, the risk of buying low-quality products is significantly reduced;

- for the installation of a ball polypropylene valve, it is advisable to use the services of a specialist, since installation is carried out using special welding equipment.

Installation of ball valve made of polypropylene

Installation of a ball valve made of PP is carried out in the same way as the installation of polypropylene fittings. Such a process is not complicated, however, it is carried out by means of special welding equipment, therefore it is advisable to have skills in working with it.

Polypropylene ball valves for water supply and heating are mounted in stages. Consider in more detail the installation process of such a product:

- First you need to prepare the welding equipment for work. To do this, turn on the soldering tool and wait a while until it warms up to operating temperature. Soldering equipment will be ready to work when the green indicator lights up.

- During the heating up of the soldering equipment, you can do the cleaning of the edges of the pipes. The edges are cleaned if the pipe is reinforced. The edges of the pipes should be smooth and free of burrs, and you should also wipe them from dust and dirt.

- A valve and a pipe are inserted into a special nozzle, which contains a soldering iron. This operation must be carried out quickly and as accurately as possible, since the reliability of the future connection depends on it.

- After the faucet and pipe are located in the tip of the soldering iron, you need to wait a while. This is necessary so that the polymer surfaces of the tap and pipe are warmed up to the desired temperature. The heating time is determined according to the instructions that are attached to the soldering equipment.

- Further, the parts warmed up to the required temperature are removed from the nozzle and joined together. It is very important at this stage to firmly hold the mating parts in order to prevent displacement.

- The opposite side of the valve is connected in the same way. If all of the above points were performed correctly, then a reliable locking unit is obtained.

Advice! If you do not have practical skills in joining polypropylene parts, then it is recommended to practice this in advance on the scraps of pipeline communication.

In this way, the installation of a ball valve made of polypropylene is carried out. Mounting threaded connections is also quite simple (using union nuts).