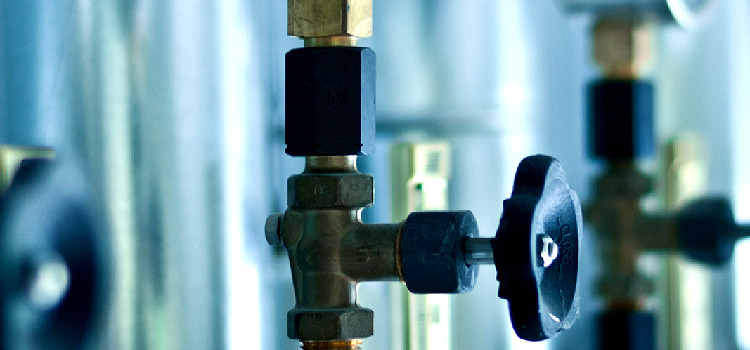

A three-way valve is a device that is mounted on a pipe in front of the pressure gauge and performs several functions at once. Thanks to this device, a purge, preventive check or complete shutdown of the measuring pressure gauge is performed. Such valves are used in communications that transport cold water, as well as hot water and steam.

The three-way valve can be installed on any device, fixture or line, where pressure gauge monitoring is required

Content

What is a three-way valve for?

Thanks to this valve, it becomes possible to check the measuring device. The pressure gauge is checked by connecting a control pressure gauge to it. Consider three more basic functions that a three-way gauge valve performs:

- this product allows pressure relief in front of the pressure gauge, which prevents sticking of the arrow of the device;

- thanks to such a device, it is possible to disconnect the manometer from communication;

- A three-way pressure gauge valve also allows purging the outlet. The elimination of contaminants affects the accuracy of the pressure gauge;

Note! For economic purposes, instead of a three-way valve, a check valve of the coupling type is often used. It is ideal for communications with low pressure readings.

Installation of this device is a prerequisite for production. This is necessary in order to carry out checks of the measuring device. If you neglect this paragraph of building codes and regulations (SNiP), the pressure gauge may fail, which will entail the inability to measure pressure on this section of the communication. In such cases, there is a high risk of an emergency and damage to the pipeline.

Advantages of three-way valves

Like any other product, a three-way pressure gauge valve has a number of advantages that are worth paying attention to:

- installation of such a crane does not require much effort;

- the device does not need individual control;

- This element of communication is easy to operate and maintain. If necessary, repair or replacement of such a device will not be difficult;

- long operational period;

- high sealing performance, which is achieved through special Teflon seals;

- low coefficient of hydraulic resistance;

- and also such a device is characterized in that there are no zones of fluid stagnation.

Three-way valves are indispensable devices in various industries. Their high performance indicators allow you to effectively cope with the tasks assigned to them.

Types of three-way cranes

To date, there are several varieties of this device. Three-way gauge valves are classified depending on the mounting method, as well as on the basis of design differences.

Consider the main types of this product:

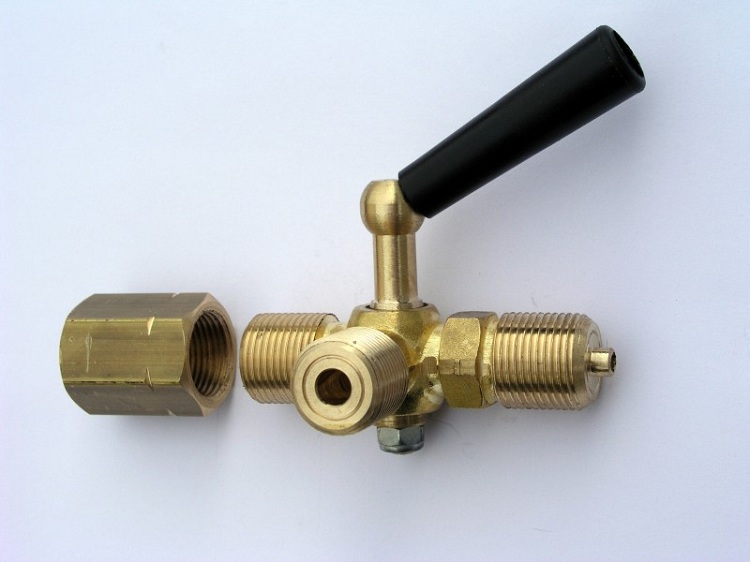

Three-way tension pith crane for pressure gauge. Such a product has a tension version of sealing (hence the name). There are 4 main varieties of cork pull valves. Consider them:

- A device in which the bore hole has pipe or metric threads on both sides. The third outlet in this case acts as a drainage.

- A device that has pipe threads on one side of the hole and metric on the other. As in the previous case, the third outlet is adapted for drainage.

- The third device is, in fact, a modification of the first and second and is equipped with a locking device. As a locking device, a handle in the form of a lever or butterfly acts.

- A device that is threaded on both sides of the hole, and on the third has a special flange for docking with the measuring device.

Such three-way valves are made of brass. Brass is a fairly lightweight and ductile material. It is worth noting that such products have two drawbacks:

- such cranes need a lot of effort to start the locking or switching mechanism;

- due to the fact that the brass alloy has low strength, there is a risk of breakage of the plug tail when tightening the nut.

Three-way ball valve with drainage for pressure gauge. A modern fixture, which is the most popular option of all three-way gauge valves.

Consider the main operational advantages of a ball valve for a manometer:

- simple and convenient design;

- high sealing performance;

- practicality (small size);

- ease of installation and ease of operation;

- no debris accumulates in flow zones;

- Three-way ball valves can be used in viscous or stagnant zones.

Helpful information! Inside the three-way ball valves there is a special ball that has a slot in the form of the letter "G" or "T". Varieties of ball valves are similar to modifications of the cork device, with one difference - the ball valve, regardless of the particular use, always has a locking handle.

Sleeve ball valve. This valve is not a three-way valve as such, but can be used to perform the same functions. Such taps are made of brass, which has a protective layer of chromium. A drainage or control gauge can be connected to the coupling output to check the main measuring device.

Three-way push-button crane for pressure gauge. This is a modern device, which has one big difference from the above devices - thanks to this valve, the constant influence of the pressure of the medium on the measuring mechanism of the device is eliminated. Measurement of pressure is carried out as follows: a button is pressed and pressure is applied to the measuring device for measuring. After releasing the button, the load on the measuring pressure gauge disappears automatically.

Features of operation of a ball three-way valve

The three-way valve is characterized in that it can be in several positions of the switch. Namely:

Regulation No. 1. The connected measuring device is connected to the communication, in which pressure indicators of the working medium are measured.

Position No. 2. In this position, the measuring device does not have access to communication, but, on the contrary, is connected to an external air environment. In this position, the gauge should always be zero.

Regulation No. 3. In the third position, the manometer has no access to either the working medium in communication or to the airspace, however, the device interacts with the external environment (when purging).

Regulation No. 4.This position of the three-way pressure gauge is used when it is necessary to connect the test pressure gauge to the main measuring device.