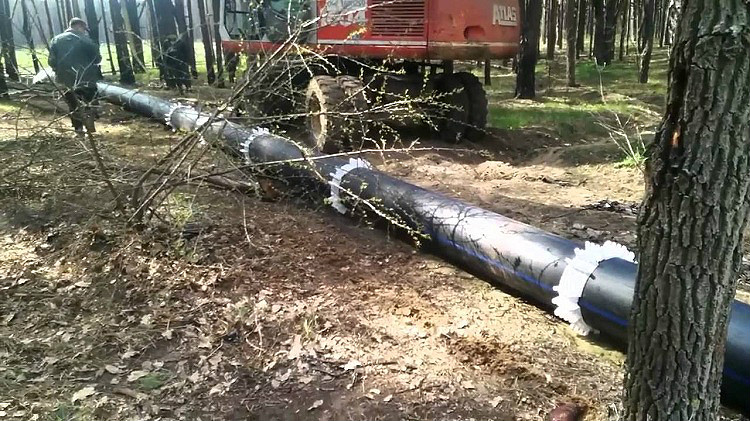

Support guide rings (ONK) or supports for laying a pipe in a protective case are devices that allow you to pull through a protective case (casing) pipes of various materials: steel, cast iron, polyvinyl chloride (PVC), polyethylene (PE), etc. They center the pipe in the casing by sealing the annular space. Installation of pipes in a case is carried out under various engineering objects: highways, railways.

Content

Features of support and guide products

Conventional supports for pipeline communications perform a number of functions. Their main “duty” is fixing the structure. In addition, thanks to the sliding bearings, linear expansion of the pipeline has no consequences. And the support-guide rings allow pulling the inner pipeline through the outer communication part (case) without causing any harm to it.

Based on this, we can distinguish several basic functions that are carried out thanks to just such a support:

- protection of the pipeline from various damages;

- protection of coupling joints and welds;

- simple and quick pulling of the pipeline through the case;

- support for the supply pipe;

- cathodic protection against corrosive influences (thanks to such a detail, the possibility of contact between the metal frames of two pipes is excluded).

Note! The use of such rings allows pulling various pipelines that differ in material, diameter, etc. These supports contribute to maintaining the integrity of the communications during pulling, and subsequent operation.

The installation of these rings is carried out at the assembly stage of the pipeline itself. Their installation does not require the use of special equipment, since the fixing of the support ring is carried out using electric arc welding. The most common materials for such supports are high-quality polypropylene, steel.

The advantages of support rings

Support rings, like any other product, have their own advantages. The main advantages of this device include:

- friction indicators, when using these polymer devices, are reduced to a minimum, therefore they are considered very reliable;

- thanks to the first point, the protective coating of the pipeline is not damaged in the process of pulling it through the case;

- the speed of installation is high enough, which reduces the cost of building the highway;

- such supports can extend the life of the communication as a whole, since contact between the pipes is eliminated and the corrosive effect is reduced;

- the supply pipe can be removed if the need arises;

- the transverse ribs that make up this support may vary in size. This allows internal communication in the center of the protective case of any diameter;

- polypropylene is a reliable insulating material and provides reliable cathodic protection of the pipeline.

Types of supports

The supports for laying the pipeline in the case are differentiated into types depending on the design features. There are three main types of such supports:

1. Support-guide ring equipped with sliding supports made of polyimiad. The latter take the load, which is formed due to the movement of the pipe through the case. Pulling steel pipes into the case using this support significantly reduces friction.

2. Support-guide ring, which incorporates rolling bearings or, as they are sometimes called, rollers. The number of clips varies depending on several factors:

- length of protective cover;

- weight of the drawn pipe;

- allowable pressure indicator on anticorrosive coating.

3. Combined PMCs, which include both types of supports: sliding and rolling. This type is quite popular when laying pipelines of small diameter (up to 30 mm) over long distances - from two thousand meters or more.

In addition to the support rings, there are other special devices that are used when pulling the pipeline through the case. These products include:

- rubber sealing cuff;

- protective cover for the cuff.

The rubber sleeve is used for sealing the annular space, as well as in the repair of communications in a protective case. The protective cover is made of fiberglass and is used to protect the rubber cuff from mechanical stress.

Specifications

PMC is characterized by strength characteristics. The materials used in the manufacture of such support rings are able to withstand pressure indicators of at least 120 kg / cm². The rollers that are used in some types of support products are also very strong and reliable and can withstand loads from 200 to 300 kg.

Support guide rings (ONK) are used for mounting transitions with section sizes up to 1420 mm. Laying pipes in cases can be made in different climatic conditions. The temperatures at which installation work is permitted vary, from region to region, from –40 to +50 ° C.

Helpful information! Such rings are firmly fixed on the pipes and are not displaced during installation and operation of the structure.

The diameter and width of the support depend on the cross section of the pipeline for which it will be used. This pattern is described in the table below.

Table 1

| Du pipeline, mm | Diameter of a ring, mm | Ring width mm |

| 1420 | 1642 | 250 |

| 1220 | 1336 | 210 |

| 1020 | 1136 | |

| 820 | 936 | 174 |

| 720 | 856 | |

| 630 | 766 | |

| 530 | 936 | |

| 426 | 542 | 154 |

| 377 | 493 | 130 |

| 325 | 481 | |

| 273 | 420 | |

| 219 | 377 | 100 |

| 168 | 286 | 85 |

| 159 | 277 | |

| 133 | 251 | |

| 114 | 232 | |

| 108 | 236 |

The weight of the product largely depends on the diameter of the product, the data are presented in table No. 2.

table 2

| Du pipeline, mm | Ring weight kg |

| 1420 | 36 |

| 1220 | 30 |

| 1020 | 24 |

| 900 | 18,3 |

| 820 | 17 |

| 720 | 15 |

| 530 | 10 |

| 426 | 9 |

| 377 | 7 |

| 325 | 6 |

| 273 | 5,5 |

| 219 | 5,2 |

| 159 | 4,3 |

| 108 | 3 |

The service life of such a support can reach 30 years (in some cases, more).

Installation of supports

The installation of the support rings is carried out in the following sequence:

- The pipeline, which is supposed to be pulled into the protective case, is mounted on supports. During installation, it is necessary to take into account the fact that the lower part of the pipeline must be free to install the supporting half ring.

- A protective gasket is installed on the pipe. A support half-ring is mounted on top of it.

- From the bottom, in the same way, the second support half-ring is mounted.

- Both halves are bolted into a single structure.

- At the end of the drawn pipe, a double guide support ring and a special head are mounted, which is equipped with a cable holder.

The supports are mounted at regular intervals from each other, the distance depends on the type of line, the diameter of the pipes and other factors

Thus, the pipeline is prepared for laying inside the protective case. The distance between the supporting elements is determined taking into account various conditions: the pressure exerted on the pipeline, the deflection of the communication between the supports, etc. The optimal distance recommended by specialists is 3 m.

In addition, for water pipelines, the distance between the supports may differ depending on the temperature of the medium. Cases for water pipes, as a rule, are represented by steel pipes with anti-corrosion coating. After the supports are installed, the protective tubes for the cables are installed.

Features of laying pipes in a case

The installation of pipelines under the motorways, as well as the railway surface, is always carried out using a case that acts as a protective capsule for internal communication.

Important! The obligatory rule that must be observed during such work is that the pipe acting as a case must necessarily have higher strength characteristics than the internal one.

The most common pipe case option today is steel products. The popularity of pipe laying in steel cases is due to the phenomenal strength of this material. Depending on the specific case and operating conditions for the cases, the following steel pipe options can be used:

- new ones;

- stale;

- restored;

- used pipes.

The protective case, depending on the situation, can be represented by the following types of pipes:

- welded spiral suture;

- straight-seam;

- Seamless hot rolled.

Seamless steel parts, as a rule, are used to equip protective cases that have a cross section of up to 273 mm. If the cross-sectional dimensions exceed this figure, then welded spiral-seam or straight-seam products are used.

In addition, steel parts for cases are often equipped with a protective anti-corrosion layer. The protective layer can be represented by the following anti-corrosion coatings:

- sand cement;

- asphalt-cement-bitumen;

- asbestos cement;

- epoxy;

- polymer.

Cases for water pipes are typically processed with extruded polyethylene. A popular solution for the case are pipes that were previously used in gas pipelines.

Methods for laying pipes in a case

When laying pipelines by the trenchless method, first the arrangement of the case is required, and only after that the inner pipe is dragged through it. The length of the case depends on the width of the obstacle to be overcome.

The choice of method for mounting the case depends on the following conditions:

- diameter of communication;

- communication length;

- hydrogeological conditions (soil moisture level);

- physical and mechanical properties of the soil (whether the soil is mobile or not);

- the capabilities of the company that carries out the laying (the availability of special equipment).

Depending on the above conditions, choose one of the following options for laying the pipe in a protective case:

- puncture;

- punching;

- horizontal directional drilling;

- water hammer.

For the construction of tunnels or collector communications, popular methods are:

- underground shield penetration;

- adit underground tunneling.

Trenchless pipe installation in a steel case is a safe way to conduct communication under any engineering facility. In addition, this method is cost-effective and safer than laying pipes in the soil. For densely built cities, this option of wiring communications is considered the most appropriate.

Important! Under the railway coating, steel pipes are used in the cases for trenchless pipe laying.

The most common way to lay pipes in a steel case is by using a pneumatic punch or a hydraulic jack. The pneumatic punch allows installation work on laying a protective case for pipelines in conditions of homogeneous soil, not more than 50 meters. Hydrojacks are also a popular equipment for these purposes and allow punctures to be performed even in unstable soils.