Laying the cable in pipes underground is a more time-consuming undertaking than air (open method), however, the reliability of this design in terms of safety is much higher. Especially popular is such a method of laying a cable in summer cottages, where there is a possibility that it can be "borrowed". Cable installation in pipes is carried out in accordance with the standards prescribed in the rules for the installation of electrical installations (PUE).

Content

- 1 The advantages of laying in the soil

- 2 What cables are allowed to use?

- 3 What pipes are used for laying cables in the soil?

- 4 Corrugated pipes for laying cables in the ground

- 5 Features of laying cable in metal pipes

- 6 Features of laying cable in plastic pipes

- 7 Trenching

- 8 Cable routing under the road

- 9 How to lay the cable in the ground?

The advantages of laying in the soil

Cable installation in the soil is carried out using various types of pipes: metal, metal-plastic, low-pressure polyethylene (HDPE). This gasket has several advantages over the air method:

- laying the cable in the pipe ensures its protection from adverse weather conditions, and also reduces the likelihood of mechanical damage;

Puseful information! The cable laid underground is very easy to replace if necessary. To do this, you just need to dig out the communication and remove the old cable from the line, replacing it with a new one.

- this method eliminates the possibility of fire, which is a very important advantage, especially for houses made of flammable materials (such as wood);

- additional protection of the wiring in the form of a pipe eliminates the possibility of damage to the cable by rodents;

- such communication (unlike air) is not visible, and does not spoil the aesthetics of the site;

- in most cases, the cost of such cable laying is lower than with open installation.

What cables are allowed to use?

According to GOST, underground is allowed to lay cable wiring, which has certain technical characteristics. A desirable parameter for cable routing in a trench without using pipes is the presence of so-called armor. Armored cables, among other things, must also have high waterproofing rates. The laying of such cables can be carried out without protective pipes, however, the cost for them is higher than for budget options that are mounted in pipe communication.

Consider the main types of cables that are allowed to be carried out in the soil without protective pipes:

- AVBBSHV. Armored cable, inside of which are made of aluminum conductors. The armor is represented by two layers of galvanized steel, coated on top with an insulating layer;

- VBBSHV. Such a cable differs from the previous one only in the material from which the wires are made - it has a copper filling. According to other technical characteristics, VBBSHV is similar to AVBBSHV. Both of these types are recommended for use for wiring electricity in summer cottages. Also, their properties make it possible to exclude the use of protective pipes.

- PvBShv.Such a cable is also an armored version, however, unlike the previous two types, the insulating material of the product is cross-linked polyethylene. This material has high strength characteristics, so it is ideal for laying underground, but its cost is higher. PvBShv is often operated in severe climatic conditions.

In addition, other product variants are suitable for underground wiring: AAShp, AAShv, AAB2l, etc. Such models of cable products are allowed to be used in soil that has normal acidity.

The following cable models are perfect for soil, which contains active chemicals of various nature (salt marshes, swamps): AABl, AAShv, AAB2l, ASB, AAPl, ASPl, AAP2l, AAShp, AVBbshv, AVBbshp, APvBbshv, etc.

Together with protective pipes, armored cables provide high reliability of communication and have a long service life. But not every owner will have enough funds to equip such a wiring. And even more so, the least profitable option is the use of armored cables and pipes. In this case, use cheaper cable products laid in the pipes.

The cable used for installation in pipes underground, as a rule, has a special marking - SIP (self-supporting insulated wire). A similar kind of cable is allowed to be used when laying in a trench method only in conjunction with a protective pipe.

What pipes are used for laying cables in the soil?

Laying the cable underground is safer than the aerial wiring method. Pipes that perform the function of a protective casing for cables can be made of different materials. Consider the main materials of such pipes and their features:

Metal. A metal pipe for cable protection should have cross-sectional indicators that are 2-3 times the diameter of the cable itself. The depth at which the cable is laid in the protective cover, as a rule, depends on the climatic features of the region, namely, on the depth of freezing of the soil. If the freezing depth reaches the depth of the trench, then it is necessary to additionally fix the pipe to protect it from damage.

Important! It is forbidden to use steel pipes for wiring power cables. Such material is only suitable for control lines.

Asbestos cement. Previously, such pipes were used quite often with the trench method of wiring installation, however, today they are used extremely rarely. Installation of such pipes is difficult due to their heavy weight. In addition, asbestos cement products have low strength indicators, and also releases substances harmful to human health. Asbestos cement products are carcinogenic and not recommended by specialists.

Plastic (PND, PVC, PP). Today, a plastic protective pipe for laying electrical wiring in a trench method is the most popular option of all. This is due to the fact that plastic communications have a number of positive advantages:

- low weight;

- high strength characteristics;

- resistance to corrosion;

- high insulating properties;

- long service life.

Plastic pipes are distinguished by a wide range of sizes and other characteristics. If necessary, you can choose a product with a smooth or corrugated wall. The most popular pipes among plastic are PND products, which are represented by the following varieties:

- light corrugated tubes;

- heavy corrugated pipes;

- halogen free;

- smooth hard;

- products with two walls.

Corrugated pipes for laying cables in the ground

Particular attention should be paid to corrugated pipes for the transmission of power lines in the soil. Such products can be of two types:

- unreinforced;

- reinforced.

Reinforced corrugated tubes are characterized by increased strength indicators. Strength is achieved thanks to a special steel wire, which is equipped with reinforced models at the production stage.

Today they are gaining more and more popularity. double-walled corrugated pipes. Such a product includes the following structural elements: corrugated outer shell, consisting of HDPE and a smooth inner shell of high pressure polyethylene (LDPE). A distinctive feature of such a pipe is a high coefficient of ring stiffness. Due to this, such models are able to withstand heavy loads. In addition, the installation of the cable into the pipe is carried out without any difficulties, since a smooth inner wall made of LDPE simplifies the process.

The light weight of the pipe also contributes to its laying, and high thermal stability indices make it possible to operate double-walled corrugated pipes in different climatic zones. In addition, the positive qualities of double-walled models include: resistance to the harmful effects of corrosion, resistance to ultraviolet rays and the service life, which can reach 50 years (in some cases, more).

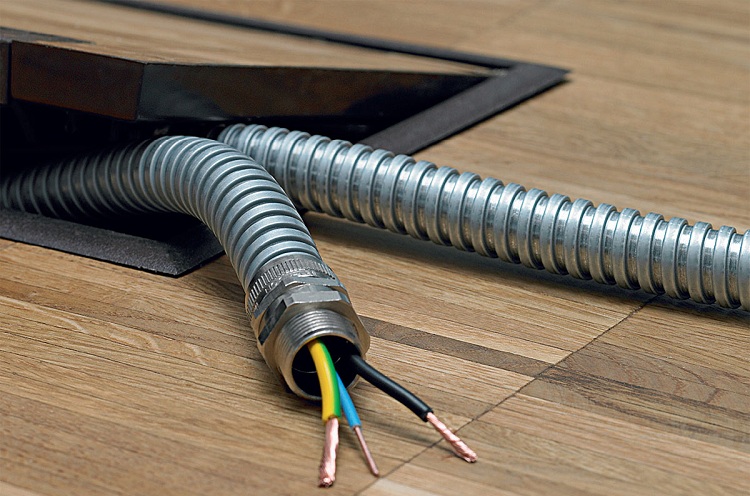

Features of laying cable in metal pipes

For wooden buildings (houses, baths, etc.) it is recommended to lay protective pipes made of metal materials. These materials include: iron or galvanized steel. The use of galvanized products is more preferable, since they have good indicators of resistance to corrosion.

It is recommended to use DCS pipes for laying cables in rooms. The trench application of these pipes is undesirable, however, if such communication is temporary, then it can be performed in the soil and from the BCS pipe. For joining of individual segments of the route, as a rule, special fittings of a threaded type are used. The use of such couplings greatly simplifies installation and reduces the time for its implementation.

Important! When laying such communication, it is worth taking care of grounding. Grounding for such structures is a mandatory measure, which is prescribed in the relevant documentation.

In addition, it is worth remembering that the slope of the route is made towards the distribution switchboard. Pipes, as well as joints between pipes, must be painted to protect the communication from corrosion. Such structures are not suitable for indoor use, since painted pipes do not adhere well to concrete poured into the floor.

Features of laying cable in plastic pipes

The installation of an electric cable in pipes made of low-pressure polyethylene has several features that are worth paying attention to. First of all, in order to exclude unforeseen circumstances, it is recommended to prepare a drawing of the future route.

It is advisable to fix the communication at certain intervals, which, depending on the particular case, can be from 60 to 80 cm. Fastening the structure is carried out over the entire length with special brackets or clips.

In order to drag the power line through the pipe, special broaches are used, with which the pipe is equipped at the factory. If there is no broach, it can be replaced with a conventional metal wire.

In contrast to the metal track, the elements of which are joined by means of threaded connecting elements, the individual segments of the plastic pipeline are docked using special soldering equipment. The electrical cable is connected using special couplings. In addition, if the communication is mounted vertically, it is recommended to slope it to exclude the possibility of condensation accumulating in it. Compliance with the above rules will allow you to get a durable and reliable design.

Trenching

The construction of a trench is an important point in installing the power line in the ground. Many turn a blind eye to this, however, the rules should still be followed. Consider the basic requirements that an underground cable routing must meet:

- the pipeline must have a depth in the soil of not less than 70 cm. If installation is carried out in non-standard climatic conditions, this figure will be correspondingly higher;

- it is important to remember that the distance of the laid communication to the foundation should be at least 60 cm. It is strictly forbidden to lay the track under the foundation;

- the width of the trench is determined by the diameter of the pipe. In turn, the diameter of the pipeline should correspond to the number of cables. If several conductors are laid in the channel, the distance between them must be at least 10 cm;

- Before setting up the ditch, it is necessary to study the plan of a particular site. This is necessary in order to select the correct location of the trench. According to the PUE, the cable is laid in the pipe at appropriate distances from other communications (the route must pass no less than 2 m from the gas pipeline, and also no closer than 1 m from the water supply);

The arrangement of trenches should be carried out according to the PUE, the laying of a signal tape is mandatory

Helpful information! In some cases, the owners use ordinary bricks to strengthen such communication when the soil sags. It is not recommended to use hollow bricks for these purposes.

- on top of the track, you must definitely put a tape that will warn that a power cable is laid here. After this, it is necessary to again fill up a layer of sand and earth (with a slide of 10-15 cm).

Cable routing under the road

Cable laying under the road in pipes is carried out with the permission of the organization on whose balance the road is located. This item is especially relevant for routes located in settlements, as other communications can pass under them. If laying under the road is carried out in a holiday village, then such an event must be agreed with the administration.

The rules for arranging the power line in a protective casing under a non-paved autopanel are the same as for conventional laying. The depth, arrangement of the sand cushion, backfill and other parameters coincide with the usual installation of communication. Laying an electric cable in a pipe is carried out under an asphalt road, as a rule, by a puncture method. A puncture involves the use of special equipment and is a trenchless method of arranging communication, however, the cost of such work is quite high.

How to lay the cable in the ground?

First of all, it is necessary to draw up a plan for laying the power cable in the protective pipe. Next, a phased installation of communication is carried out. Consider the process of installing communication using digging a trench:

- Initially, the pipe is laid at the bottom of the trench. The bookmark is done on the soil with a sand cushion. The sand layer should be at least 10 cm.

- Next, a cable is drawn using wire.

- At the third stage, communication is covered with a layer of sand (so that the pipe is not visible).

- After that, we fill the trench with a layer of earth and ram our feet.The layer should be approximately 15 cm.

- We put on top of the trench a signal tape that performs a warning function.

- Then the canal is completely covered with earth and rammed.

Note! After laying, it is necessary to conduct a test measurement of the cable insulation.

Such work can be done without much effort with one's own hand. In order not to encounter difficulties while laying the cable in the pipe, it is recommended that you carefully consider the issue and study all the rules and regulations related to the installation of such communication. In addition, it is recommended to contact an electrician who will advise you on this issue.