The chimney is one of the most significant and important elements of boiler equipment. The efficiency of the heating system, the nature of fuel combustion and the removal of combustion products depend to a large extent on it. Modern chimneys are made of different materials. There are metal, and ceramic, and brick, and even glass pipes. For a chimney of complex configuration, it is best to use a metal corrugated channel.

Content

Technical data stainless steel corrugated pipe

Among the important technical indicators of corrugated stainless steel pipes are the following:

- working temperature: -50 ° С - + 110 ° С;

- pressure at a working temperature of + 110 ° C: 15 bar;

- possible bending radius of the product depending on the diameter of the pipe: 25-150 mm;

- thermal conductivity: 17 W / (m * K);

- linear expansion: 17;

- roughness coefficient: 0.008.

Corrugated pipe is resistant to pressure drops (limit value 50 atm). The maximum fracture pressure is 210 atm. Other indicators of pipes are given in the table.

Table 1

| Index | Value | |||||

| steel grade | 304 | |||||

| Diameter in mm | 12 | 15 | 18 | 20 | 25 | 32 |

| Outer diameter in cm | 1,62 | 1,81 | 2,0 | 2,56 | 3,2 | 3,76 |

| Inner diameter cm | 1,18 | 1,41 | 1,78 | 2,1 | 2,7 | 3,2 |

| Wall thickness in mm | 0,3 | |||||

| Weight of one meter corrugated pipes, kg | 0,13 | 0,156 | 0,164 | 0,2 | 0,23 | 0,28 |

| Corrugation pitch in cm | 0,425 | 0,476 | 0,5 | 0,5 | 0,526 | 0,56 |

Types of flexible pipes for chimneys

The modern market for corrugated pipes offers various types of these products. But not all of them meet safety requirements and can be used for a chimney. Distinguish designs from aluminum and stainless steel.

A safe chimney for a fireplace or stove can only be built from stainless steel pipes and accessories

Some time ago, aluminum pipes were used for chimneys of columns and gas heating appliances. This multilayer corrugation is a tube made of laminated foil having a diameter of 10-15 cm. It is durable and cheap. In order to give the necessary shape, a steel wire is inserted inside.

In the compressed state, the aluminum pipe has a length of 650 mm, and when stretched, up to 3 meters. Metal tape can increase the duct.

Note! Boilers and fireplaces that run on solid fuel do not have an aluminum pipe, because it is not able to withstand high temperatures.

Currently, such a corrugation is not recommended at all.

Stainless steel corrugated pipes are structurally similar to aluminum ones, but their characteristics are much better. The material can withstand temperatures up to 900 ° C without affecting the design of the channel and at the same time effectively remove the products of combustion of devices on liquid, solid and other types of fuel (boilers, fireplaces, stoves).

Corrugated Products

Corrugated stainless steel pipe for the chimney is made of multilayer foil. Its strips (0.12-1 mm thick) are connected by a special locking method and fixed to a spring made of stainless steel.This design allows you to bend the pipe at 120-180 ° and stretch it to a length exceeding the original, more than 3 times. The stretching / compressing procedure can be repeated several times without violating the integrity of the pipe.

Depending on the capacity of the boiler or furnace, a corrugated pipe of a larger or smaller diameter is selected

For chimneys, corrugations from stainless steel are produced in various diameters, which allows you to choose the required size corresponding to the outlet pipe of the heating device.

In order to increase the operational life of the chimney, it undergoes processing with a special solution from both the inside and the outside. Such manipulation protects the channel material from chemically active substances and aggressive media. The minimum service life of a metal corrugated pipe for a chimney is 20 years.

Installation of chimney corrugated ducts requires insulation. As a heater for such pipes, basalt cotton wool is produced in rolls. It is suitable for both indoor and outdoor installation. The insulated corrugated stainless pipe does not heat up externally.

Key Features of Corrugated Pipe

Corrugated stainless steel for chimneys has a circular cross section. Its standard length in many cases makes it possible to obtain a chimney duct without unnecessary joints.

Note! The tightness of the chimney pipe directly depends on the number of connections that are used to assemble it: the fewer joints, the better.

Stainless steel is the main material for the manufacture of corrugated chimneys. It is durable, has anticorrosive properties and is heat resistant, which increases the service life of products. During the kindling of a boiler or furnace, condensate containing some H2SO4 (sulfuric acid), incapacitating many chimneys from other materials. Therefore, this type of pipe is used more often than others.

The stainless steel pipe design increases the mechanical strength of the entire channel by compensating (up to 50%) the linear expansion of the initial pipe size when exposed to temperatures and vibrations.

Important when choosing a species chimney pipes is the possibility of their adoption of different shapes and configurations. Corrugation allows for repairs and install it in a channel having a large number of bends. When buying a corrugated pipe, it is necessary to check it for mechanical damage or kinks so that there are no problems during installation.

Pros and cons of corrugation

Corrugated pipe is applicable for any chimney systems, even at very high exhaust gas temperatures.

It is resistant to:

- humidity;

- high temperatures;

- chemically aggressive environments.

Such a pipe is used not only for the chimney, but also in air conditioning and ventilation systems. Its flexibility allows you to easily install a chimney in the presence of complex architectural structures: sloping ceilings, floor beams, built-in columns, etc. A similar feature of a stainless steel corrugation for a chimney reduces the cost and laboriousness of installation work.

For installation, expensive components (adapters, angles, bends) are not required; this is important if the budget is limited. Among other advantages, it is possible to note the possibility of connecting pipes of different diameters into one design. For this, special adapters are used.

Corrugated pipes have a few shortcomings: a short service life and the need for insulation to combat the formation of condensate. In addition, the thrust in the corrugation is much lower than in a smooth pipe, so it is not recommended to perform a vertical channel from such a product along the entire length.

Chimney installation requirements

When installing flexible chimneys, it is necessary to observe some important requirements that will ensure reliable and efficient operation of the duct. Among them are:

- fastening using an adapter;

- correspondence of the diameter of the chimney duct to the outlet cross section of a specific heating device;

- placing the corrugated pipe in a fireproof case when crossing through the floor;

- providing double wall thickness of the outer protective casing in order to ensure the safety of the structure in case of possible damage to the outer layer;

- tight fastening of the corrugated pipe to the heating system, preventing gas leaks;

- the length of the channel section from the bottom of the pipe to the horizontal section of the flexible chimney is not less than 50 cm;

- ensuring the radius of curvature of the installation of the corrugated pipe is not less than its diameter;

- the distance from the wall or ceiling to the connecting pipe is not less than 50 mm if they are made of non-combustible material;

- if the wall is made of another material, this distance should be at least 250 mm;

- ensuring vertical connection to the boiler;

- the total length of the installed horizontal sections is not more than three meters;

- installation of a flexible chimney with a bias to gas equipment more than 0.01 degrees.

Installation of stainless steel corrugated pipe

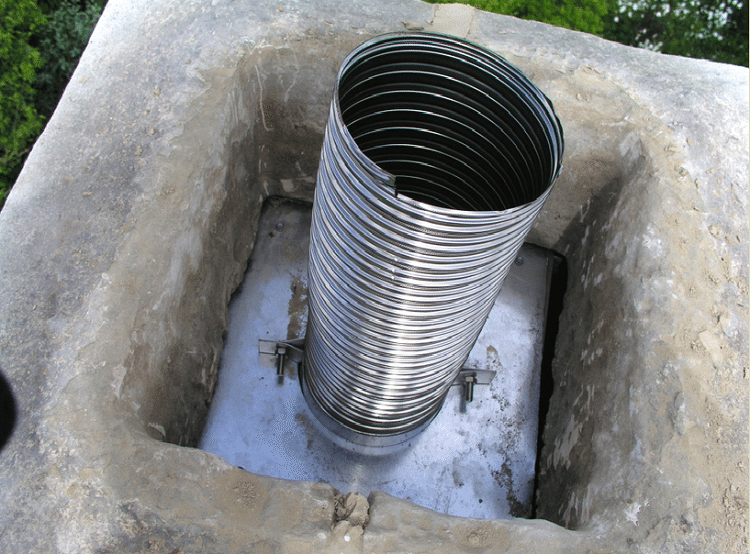

Corrugated pipe is applicable for the installation of adapters that match the outlet of the device with the main channel of the chimney, repair (sleeving) having bends of brick chimneys. For them, both external and internal installation is possible.

The stainless corrugation for the chimney is fastened with special metal brackets. They are either included in the kit to the pipe, or are implemented as a separate holding element. Fixation is provided by ordinary clamps, which are tightened with an open-end wrench.

Note! When installing horizontal sections of corrugated pipes, it is necessary to exclude their sagging.

During installation, no more than three turns of the corrugated chimney are allowed. For joining the two pipes, metal tape is used, which ensures high tightness of the docking unit and prevents leakage of combustion products. Installation does not require the use of sealant to seal the connections of the elements of the chimney.

A stainless steel corrugated pipe can be a good alternative to using rigid chimneys, despite a shorter life.