A correctly installed chimney is the key to the effective operation of the entire heating system in a private house. Regardless of which boiler device is supposed to be solid fuel or gas, the chimney must comply with all regulatory indicators. Before designing your own boiler room, you should understand what types of chimneys exist and what rules relate to their installation.

Chimney pipes are made of different materials and are selected depending on the type of furnace or boiler

Content

Which pipe is better to use for a chimney in a private house?

The optimal choice of the chimney for the boiler is based on the following points: strength, ability to withstand high temperatures, inertness to aggressive acids. In today's market you can find models asbestos cement pipesstainless steel or ceramic. What kind of chimney is better to use in each particular case will be dictated by the type of furnace equipment and its characteristics.

Traditional brick chimneys, for many decades used in the construction of home boiler houses, are gradually becoming a thing of the past. Such chimneys are used mainly for solid fuel boilers. Despite the rather aesthetic appearance and high heat resistance, they have a number of significant drawbacks. Brick pipes for the chimney are laid out sequentially, which requires a certain amount of time. The quality of the laying of bricks in the chimney is also not the last factor in the proper functioning of the system. Laying a brick yourself is quite difficult, this process often requires the help of a specialist. The passage of such a pipe through the roof may require disassembling the roof if the pipe is laid out in an already finished building.

Unlike brick, the installation of steel chimneys for boilers is simple and relatively budget. Stainless steel flues lend themselves well to dismantling and repair. In order for such chimneys in a private house to serve as long as possible, they should be of high quality insulate (isolate). The duration of the operational life of the system depends on this procedure.

Brick chimneys are installed only for solid fuel stoves, for other types of boilers an alternative should be selected

Helpful advice! The best option for the design of pipes for the chimney for the boiler is the so-called “sandwich”. Ready-made pipes of this type are also on sale, as well as insulation of the “sandwich” type can be done with your own hands.

Another common type chimney pipes for gas boiler are coaxial chimneys. For solid fuel boilers, such a pipe for a chimney is not suitable, since their combustion chamber is made in a closed type. A special form of coaxial chimney eliminates the formation of condensate, which is especially important for gas boilers.

Types of industrial chimneys

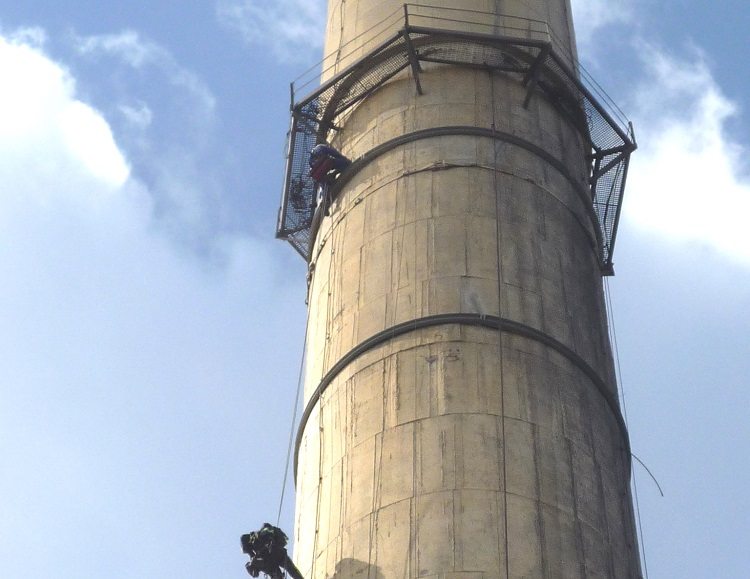

Industrial chimneys are used for the same purposes as in everyday life - for the removal of fuel combustion products. The interior of industrial chimneys for industrial-scale boiler rooms must be smooth to prevent soot and other harmful substances from settling.

It's important to know! Industrial chimneys need constant maintenance, otherwise their performance will deteriorate. Such chimneys must be constantly cleaned of soot and dust deposits, especially in the absence of a heating season.

Industrial chimneys for gas and solid fuel boilers are rarely made of metal, with the exception of structures up to 30 m high. This type of pipe is called self-supporting. Metal industrial pipes also need insulation. If the design is multi-barrel, then all trunks should be insulated.

Smoke industrial pipes with a height of up to 80 m are more appropriate to build from brick. A large construction height requires the use of concrete or reinforced concrete. Varieties of industrial chimneys can be equipped with lightning rods, light barriers and service areas.

Also, one of the functions that industrial chimneys perform is to provide traction in boiler units. The creation of smoke draft in the boiler is due to the temperature difference between the gases emitted during combustion and the environment. At the same time, hotter combustion products tend to rise.

General rules for designing a boiler house in a private house

The rules by which chimneys are installed in private buildings depend on the type of building. The choice of location for the location of the boiler room depends on the type of fuel. For a solid fuel boiler, a separate non-residential premises should be reserved. It must be equipped with supply and exhaust ventilation. For a solid fuel boiler, less stringent rules are presented than for a gas boiler, since solid fuel is less explosive.

Placement of a gas boiler in a private house can be as follows:

- a separate room in a private house - ground floor, basement or attic.

- extension or detached building.

The reliable operation of the heating system depends on the installation of the chimney pipe for the gas boiler. Rules for chimney pipes in a private house:

- The chimney section is selected in accordance with the technical requirements of the gas boiler. The diameter of the chimney pipes for a gas boiler is usually indicated in the technical passport of the boiler installation.

- It is advisable to choose cylindrical pipes for the chimney for gas boilers: they are easy to maintain and clean.

- The design of the chimney pipe must not have more than 3 bends or turns.

The parameters of the height and diameter of the chimney for a solid fuel or gas boiler are determined in accordance with the heat transfer of the system. The diameter of the chimney pipes from the gas boiler is proportional to the mass of fuel consumed per hour. The same calculations are also relevant for a solid fuel boiler.

Helpful advice! There are standard indicators for domestic heating structures. The temperature of the gases at the outlet to the pipe is usually 150-200 degrees. The gas velocity in the chimney is 2 m / s, the gas pressure per 1 m is not less than 4 Pa.

SNiP rules determine that the minimum chimney height cannot be less than 5 m. With the above data and a fuel consumption coefficient of 10 kg of fuel per hour, the diameter of the chimney pipe will be at least 165 mm. The dependence of the heights, power and pipe diameter for a gas boiler can be calculated according to the following table.

Table 1

| Power | Pipe diameter | Height |

| 18 kW | 130 mm | 7 m |

| 28 kW | 150 mm | 8 m |

| 45 kW | 150 mm | 9 m |

| 65 kW | 200 mm | 10 m |

| 90 kW | 250 mm | 11-13 m |

Rules for the passage of the chimney pipe through the roof

The next question that can cause trouble with installation of the chimney, is its passage through the roof. Getting to the conclusion of the chimney pipe, you need to know the main regulatory rules.

Experts advise to place the passage of the chimney through the roof closer to the highest point of the roof. At the same time, the distance between the “ridge” of the roof and the middle of the chimney should be at least 1.5 m. And the chimney for the boiler rooms of a private house should be 0.5 m above the “ridge”. These rules are “convenient” in that on the roof A large crust of snow will not collect around the chimney of the house, which, when melted, increases the risk of roof leakage.

The device for the passage of the chimney through the roof has features that depend on the shape of the chimney and the material of its manufacture. The design of the site in the place where the brick pipe passed through the roof has completely different methods of sealing than in the case of metal or ceramic chimneys.

An important factor is the distance between the rafters and the roof. It, as a rule, is about 25-30 cm. In the event that the roof is made of combustible materials, a gap of 13-25 cm is observed between the roof surface and the wall of the chimney. With a fireproof roof, this indicator can be minimal.

Helpful advice! The material of the roof itself is also important. For various types of roofing, special elements are available on sale that contribute to better waterproofing of the joint.

If the roof has a slope, respectively, the passage of the pipe through the roof should also be made at an angle. To do this, use elastic penetrations, which also give a sealing effect. Roof penetrations are in the form of a multi-stage pyramid. If you plan to pass a metal pipe through the roof, it is better to use sealing elements made of elastic aluminum. They are well combined with any roofing materials.

The penetrations can be of different configurations and sizes. Which one is better to choose in this or that case - the following rules will determine:

- straight seals are used on flat roofs and roofs with a slight slope (up to 25 degrees);

- corner penetrations with flange fastening at an angle of up to 20 degrees are used for roofs with a slope of more than 25 degrees.

It is best to frame the place of pipe passage through the roof with universal penetrations that have the ability to change configuration.

Metal and silicone seals are attached to the roof with rivets or self-tapping screws. The flange is hardened with sealant. The passage of a square pipe through the roof of the house can be formed using a collapsible apron - a penetration-casing of metal.

Providing your own home with heat is not an easy task, and the most important point in it is the removal of fuel combustion products from the boiler. The choice of materials for the chimney and its installation must be approached with all responsibility, after having studied the rules and requirements for installing such systems. Non-observance of the norms will lead to problems with heating, and in the worst case, to the penetration of smoke into residential premises, which is very dangerous for health and life.