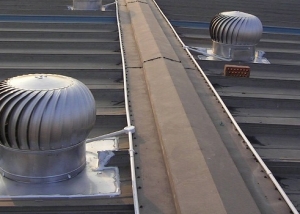

Ducts are the main structural elements of ventilation systems through which air is transported (removing stale air from the room and delivering fresh). In addition to ventilation communications, these products are used in air conditioning systems. To date, there are several varieties of these elements produced using various techniques.

Modern technologies allow the production of metal and polymer ducts, flexible and rigid, of different sizes and shapes

Content

Operational area

Ventilation systems are communications that are necessary and fulfill a very important function, namely: they circulate air in residential premises. Such systems are used in various areas of human life. Consider the main operational areas of these systems:

1. In residential premises of apartment buildings and private houses. For the installation of ventilation systems for economic purposes, as a rule, round ducts are used. However, rectangular air ducts can be used for house ventilation, and round ventilation pipes in this case are used only for connecting the communication with the exhaust device, thus acting as a transition element. Residential ventilation structures control air purity, humidity and dust, and also help eliminate odors.

2. At various manufacturing enterprises. For the organization of ventilation in production, circular ducts are most often used, which are distinguished by high throughput rates. The material for round ducts installed in the production, in most cases, is galvanized steel. Designs from such pipes do an excellent job of removing smoke, carbon dioxide, various chemical compounds, etc.

Helpful information! The cost for round products is lower than for rectangular analogues, therefore, the organization of such ventilation is more profitable from a financial point of view.

Ventilation systems are installed in buildings and structures of all types and for any purpose, the largest and most powerful are created for manufacturing enterprises

3. In sanitary facilities. Today, medical facilities are equipped with ventilation ducts assembled from round pipes. This is due to the same high throughput of round ducts, which allows for fast and high-quality removal of unpleasant odors, as well as reduce the concentration of carbon dioxide in hospital wards. High-quality air circulation through such channels can improve the indoor climate and reduce the risk of the spread of an infection.

4. In catering establishments. Buildings that relate to catering buildings, in most cases, have ventilation made of round pipes.In this case, it is very important that the pipes are made of a material resistant to corrosion, therefore galvanized or polymeric air ducts are used in public catering. The main functions of these systems are the removal of smoke, odors, as well as maintaining a normal coefficient of humidity in the premises.

Types of ventilation ducts

All existing ducts are divided into two main types:

- hard;

- flexible.

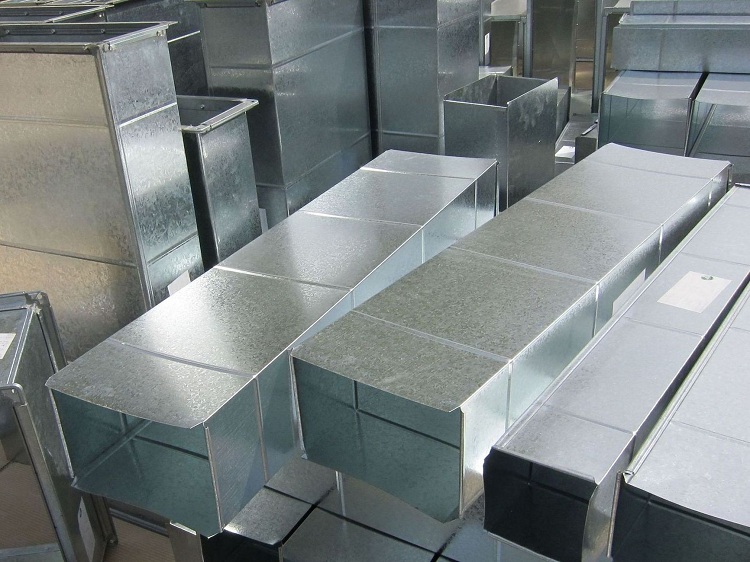

Rigid ventilation ducts are mounted from rectangular or round pipes, which are made of galvanized steel or aluminum. The set of equipment used to produce such ducts is called an automatic line.

Rigid ducts have several advantages that are worth paying attention to:

- the cost of such products is lower than for plastic counterparts;

- ease of installation;

- high installation speed;

- resistance to corrosion;

- fire resistance;

- low drag coefficient and, accordingly, high throughput performance.

Flexible ducts are used much less frequently for ventilation. Its use, as a rule, is determined by the need to organize ventilation in a complex (by design) and compact room. They are often used for active ventilation communications, among which there are exhaust systems equipped with a fan.

Flexible ducts have a higher cost compared to rigid counterparts. It is recommended to start the production of air ducts precisely with rigid models, since they are more in demand in the modern market. The manufacturing process of rectangular or round galvanized ventilation pipes is not particularly difficult.

Round and rectangular ducts

All ducts are divided into two main varieties, depending on the shape of the section:

- rectangular;

- round.

Round. Such ducts are less expensive, which affects their popularity. Products of this shape are characterized by high throughputs and do not require large space when organizing a ventilation system. Ventilation pipes of this shape are able to withstand higher pressures than rectangular counterparts.

The most popular materials that are used to produce circular ducts are:

- plastic;

- galvanizing.

Helpful information! Round ventilation pipes are easy to clean, which is an important advantage.

Such ducts are more functional and are used to achieve maximum results. Communication made of round pipes also has a good stiffness coefficient, which affects its service life.

Rectangular Air ducts with this sectional shape are used for private purposes much less often, however, their use for organizing house ventilation has its advantages. First of all, we note the aesthetics of these products. Due to the rectangular shape, the installation of such products can be made as compact as possible, close to the working surfaces of the room. Visually, such an air duct will fit much more organically into the interior of the room. During the installation of such ventilation pipes, one important rule must be remembered: it is best to install them under ceilings.

Rectangular ducts are also used in enterprises of various kinds. The main disadvantage of products with this cross-sectional shape is low noise insulation qualities, so in the case of private use of rectangular ventilation, the organization of additional insulation is often required, which increases the overall financial costs. Experts recommend the use of rectangular polymer ducts for laying inside apartments and private houses, as they are distinguished by higher soundproofing qualities.

Duct manufacturing equipment

Separate elements of ventilation communications are made according to the drawings. Their manufacture is governed by standard specifications. If steel (black or galvanized) acts as a material for air ducts, then the products are obtained in a spiral way. This method includes several options:

- production on folds;

- the implementation of ventilation pipes using welding equipment.

In addition, products made from other materials are also made on welding or folds. Let's consider them in more detail:

- titanium;

- aluminum;

- stainless steel.

Welded longitudinal flanging technology is very popular. This method takes into account the use of specialized equipment that performs resistance welding of products. Special equipment is also used to make titanium ducts. This is due to the fact that titanium is a very strong metal and requires a special approach. Welding of titanium ventilation elements is called argon arc and it is performed using special electrodes.

The folds on the ventilation pipes made of stainless steel or aluminum must necessarily comply with technical standards and have certain dimensions. The rebate cross-section should be 500 mm. The folds are fixed by spot welding, and rivets are also used for their fastening. The folds must be located at the end and at the beginning of the segment of ventilation communication.

Rectangular duct production

As mentioned above, rectangular (or square) ventilation communications can be laid both in private and for industrial purposes in industrial enterprises.

Joints of products are sealed with the following methods:

- welding;

- soldering;

- mechanical lock.

The production process aimed at the manufacture of rectangular products is not particularly complex and includes several main stages, which are worth paying attention to:

- First of all, on a conditional, unfolded on a plane surface of the duct, a sheet of metal is cut.

- The second stage is formative and proceeds using bending equipment that bends the workpiece. Bending of the workpiece is carried out before giving it the shape of the duct.

- At the third stage, joints are sealed.

To date, the simplest method of sealing the joint of a product is considered mechanical. The organization of the castle not only speeds up the production process, but also reduces overall labor costs. The main disadvantage of this technology is that it reduces the sealing performance of the part. In addition, additional material is spent on the lock.

Helpful information! A mechanical lock is the optimal solution for ducts that have a small wall thickness and a similar length.

For fastening ventilation pipes in the longitudinal plane, soldering can also be used. Soldering, like organizing a mechanical lock, requires a small wall thickness (up to 1.5 mm). The use of soldering allows you to achieve good tightness of the duct.

Sealing joints of ventilation segments can be done using welding equipment. As a rule, welding is used for ventilation pipes, the wall thickness of which exceeds the figure of 1.5 mm. Ducts obtained by welding have the highest tightness and good reliability.

Production of round ducts

Round ducts are widely distributed on the modern market and are produced on a large scale for use in economic and industrial purposes. The low cost as well as high throughput of these products makes them popular. The material for the manufacture of round ventilation pipes in most cases is galvanized steel.

Today, there are two main ways of manufacturing ventilation pipes with this sectional shape:

- Bending on a machine equipped with rollers. The sealing of the seam formed on the rolling equipment of the part is carried out by two methods: welding and organization of the rebate lock.

- The second method of manufacturing air ducts involves the use of a special winding machine.

Rolling ventilation products has undeniable similarities with the technology of production of rectangular models. In turn, the use of a winding machine simplifies the production of these products, since one of the steps, namely: sealing joints, is excluded. In addition, air ducts made in a coiled way can have non-standard sizes, therefore this technology is used to produce unique ventilation pipes on order.