A coupling is a connecting piece with which to mount a pipeline structure. Without connecting elements, the pipeline will be a straight section consisting of one pipe of a certain length. Modern pipeline structures are characterized by the presence of many parts that have different options for docking with each other. Also, they can have different angles of rotation, so during installation can not do without this type of parts.

Content

Features of the connecting elements

The choice of fittings for metal pipes is very wide and diverse. In plumbing stores, you can find a coupling for any type of connection. Couplings, which are used as connecting elements for installation of pipelines, are a type of fittings. They perform a unifying function, and are attached using a special thread. The thread may be on the inside or outside of the part. In addition, there are products that include both versions of the thread.

The coupling is a hollow, all-metal or other cylinder made of other materials (the material is selected depending on the type of piping). Polypropylene products that connect parts of plastic pipes into a single design are very popular. Such parts are connecting and transitional. In the second case, they are mounted using additional materials that improve the quality of the connection. Such materials include: FUM tape, linen thread.

Important! Reducing couplings are used when joining pipes with different diameters.

In addition, there is a combined coupling, which is used when connecting parts from different materials. This type is equipped with a special thread. Using the combined type, you can easily connect plastic and metal products, etc.

Couplings

Today, there are several types of these connecting elements, each of which has unique qualities. In addition, there are universal options that can be used in almost any case.

The most common coupling option is a part in the form of a hollow cylinder with different types of fastening

The main types of couplings:

- Threaded - before such details were the most popular type and were used everywhere. Now they are used much less often, mainly for steel pipes. Differ in rather difficult installation. This type of connection is not reliable enough.

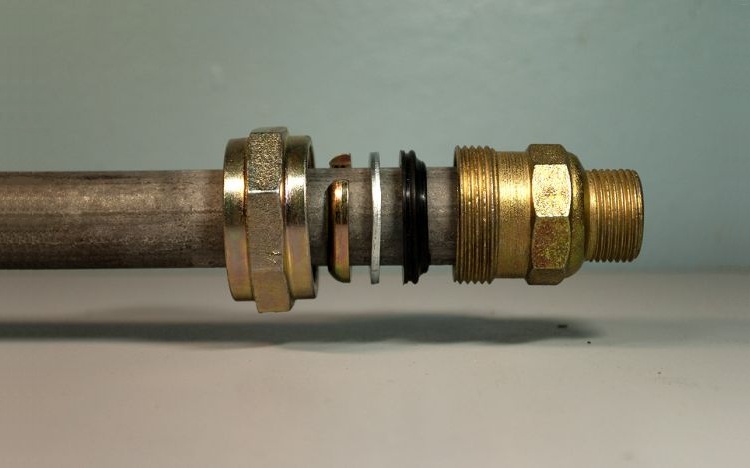

- Compression - in their structure resemble threaded ones. When mounting such products, the connection is tightened with special nuts. For a higher tightness rating, rubber o-rings are used in such parts.

- Press models - such parts are often confused with crimps. However, they differ from them in that they are equipped with special tools.

- Welded - used in the assembly of pipelines from a polymer material.

- Electric welded - a variation of the previous type.

Varieties in connection form

Couplings that connect parts of steel pipelines of different lengths and diameters are used more often than other connecting elements. This is due to the fact that metal structures are produced in the form of small segments. They are divided into the following varieties:

Corner. This type is used if you need to change the direction of the pipeline. It is very popular due to the fact that this option is much simpler than more laborious bending of pipes.

Direct or simple. An easy option to connect two metal products. Such parts are indispensable if you need to repair a damaged section of the pipeline and quickly connect it to another pipe. This type of fittings is also used when joining pipes that differ in diameter or material.

Tee fittings. They are used when docking three pipes. One of them as a result of such a connection will be located perpendicular to the other two. Thanks to this type of connection, the pipeline can be diverted at an angle of 45 or 90 °. Tees are used for pipes with both equal and different diameters.

Cross fittings. The name speaks for itself. 4 pipes are connected together, located in the same plane and located in relation to each other at an angle of 90 °. Very easy to install and do not require any special equipment. In addition, there are crosses located in two planes, but this type of connection is used very rarely (most often for production purposes at different enterprises).

Steel pipe joint

For steel pipelines, as mentioned above, threaded and compression types of fittings are used. Let us examine these two types in more detail.

Threaded

The coupling coupling (for metal and other types of pipes) steel. It has the appearance of a hollow cylinder with thick walls. Such a part is made mainly of black or stainless steel and has the usual, one-way thread inside.

When the pipe is connected to it, the pipes wind up on both sides of the coupling. Due to the fact that this connection is not reliable enough, it is carried out using additional insulation materials, which increase the degree of sealing in the thread area.

Important! Due to the fact that steel couplings do not differ in their anti-corrosion qualities, they are often replaced with brass products. No brass alloy pipes are produced, but brass couplings are common everywhere and are a very popular connector. Their positive qualities, in addition to corrosion resistance: ease of installation, versatility, relative low cost.

If the threaded connection is made of steel alloy, then you can, without fear, apply great effort. The disadvantage of this connection is that disassembling this type of thread is very difficult. This is due to the fact that during installation, water condensate contributes to the "sticking" of the components of the connection to each other.

Based on this, it is advisable to choose parts for joining steel pipes from an alloy of brass or cast iron. Such parts have the best performance.

Connection with the drive: this type of threaded connection is used if the elements of the pipeline cannot rotate around its axis.

Compression couplings

In these products, a rubber ring and a special union nut are used as additional sealing. Such parts are similar to couplings for plastic pipes, but they have significant differences in their functionality.

Compression fittings have a number of features:

- connection with this type of fittings is easy to disconnect. If necessary, the part can be easily dismantled and replaced;

- steel pipes are joined by compression elements without threading.

- when installing a compression fitting, a very important point is the cleaning of the pipe from paint or rust;

- are a less reliable type of pipe connection. Requires additional fixing materials. Such couplings are a popular fixture for temporary pipe repairs.

Note! In the case of a temporary connection, universal couplings are usually used. Such a fitting has a thread on one side and a compression docking device on the other.

Mounting couplings on steel pipes

When installing steel pipes, the ends of the workpieces are primarily cut. It is very important that the cut is smooth. Next, the desired fitting is put in place of the cut (a coupling for steel pipes), positioning it so that the central part is opposite the pipe. Then its marking is made, by which the position of the connecting part will be determined. It can be done with a marker.

The coupling must be located on the pipe evenly, without distortions, otherwise the connection will not be tight

The next step is to treat the ends of the pipes and the coupling with a special silicone-based lubricant. At the final stage of installation, pipes are inserted into the fitting according to previously marked marks. Pipe No. 2 is aligned along the axis with the first and put on the fitting (also strictly according to the marks). Fixing a fitting depends on its type.

Couplings for cast iron pipes

Two types of connecting elements are used as pipe joints in cast-iron water pipes.

With rubber seal. The principle of operation of this connection resembles in its type the joining of plastic pipelines. Its significant difference is that it is much more massive, and due to its weight it is more difficult to install.

Couplings for connecting pipes for embossing. This type of connection of piping systems has been used for over 100 years. Its feature is the presence of two sockets, which are directed in opposite directions.

The sewer system for the discharge of wastewater and other substances is mounted from pipes that are made of gray cast iron. Such cast iron has increased strength indicators. Subject to all the nuances of the installation of pipelines made of this material, the service life can reach 50 years. Cast iron pipes are manufactured with or without bells. And to combine elements with a smooth surface, the following types of couplings are used:

- Sliding. Installation of this type of couplings is carried out in a hidden way. With this connection, dismantling is not possible without disconnecting the line.

- Repair convoluted. The composition of such couplings includes two main parts in which a rubber or plastic gasket is used. In addition, fittings of this type are equipped with special clamps and connectors for connection. They are often mounted on problem areas of the pipeline that need frequent repairs.

- Plastic This type of fittings can be used several times. Reusable applications are the main distinguishing factor of such a coupling.

Mounting couplings on cast iron pipes

In case you need to combine two segments of the pipeline with a smooth surface, use a connecting piece for caulking. Such connecting elements are made of strong gray cast iron. The extender on such elements is located on both sides.

Installation of the coupling for metal pipes made of cast iron is carried out by inserting the ends of the pipes into the sockets (to the stop).

Then the pipe is equipped with an additional seal, so that the design acquires the necessary strength and reliability. As a sealant, a stub or graphite oil seal is used.

If the clutch needs minting, then this process is carried out with a solution based on cement or asbestos-cement compound. In this case, the sealing element is completely filled with the solution that is more suitable for a single case.

Important! It is very important to note that the filling of joints with a solution should occur only after the pipeline is fully assembled. Otherwise, the solution will simply crack and seal necessary for the normal functioning of the pipeline will be broken.

Couplings for copper pipes

Connecting elements for pipelines made of copper material are reliable. One of the most reliable and durable types of connections. In addition, it is a fairly prestigious option and, accordingly, this is reflected in its price.

Copper fittings are more expensive than other fittings. There are such types of couplings for copper pipes:

- threaded fittings;

- compression;

- capillary

- press fittings.

It is very important to remember that in the connections of parts of pipelines made of copper, you must always use fittings from the same material. This is a necessary rule. In this case, the copper pipeline will last a long time and without failure of its elements. Couplings from other materials are used only if necessary, for example, for temporary piping.

The coupling method is the most popular type of connection. They have a huge number of types and types according to the method of fastening, in the form and features of the application, which allows any kind of connections necessary in the installation of pipelines. In order to choose the part you need, it is worth considering a number of important indicators: the material of the pipes to be connected, the diameter, wall thickness, temperature of the transported medium, the length and shape of the future design.

Given all of the above indicators, you can choose the perfect connection that will serve you for a long time and efficiently.