Pipes are a structural element that is used in the installation of pipelines of various kinds. To date, there are many varieties of these products. There are outdated, but still popular parts and modern options, from which reliable and durable communications are mounted.

Content

What are the pipes?

All pipes for pipelines are classified according to several important parameters. Consider the main ones:

First of all, these types of pipes are distinguished by diameter:

- small;

- medium;

- big ones.

A small part has a cross-sectional index from 5 to 102 mm, medium - from 102 to 426 mm, and products that are considered to be large - above 426 mm.

Note! Another important factor by which all pipes are shared is throughput. The throughput directly depends on the diameter of the product and the characteristics of the internal walls, as well as on the number of bends in the pipeline.

In addition, they are classified by such indicators:

- according to the material of manufacture;

- along the cross-sectional profile;

- by size;

- by the method of connection;

- by type of insulation.

Some types of pipes are equipped with insulation, such products are used in the construction of heating networks and hot water pipes

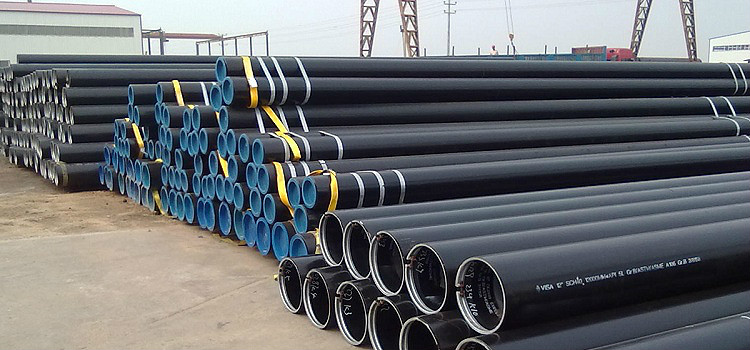

Steel pipes

Steel products are considered an obsolete option for the installation of plumbing and other systems. But, nevertheless, they are still in certain demand. By themselves, they are unstable to corrosion, therefore, they need a protective coating. As a rule, the protective layer is made of zinc - such products are called galvanized.

First of all, such pipes are divided into:

- suture;

- seamless.

And after that, according to the specifics of production, to:

- galvanized;

- welded;

- hot rolled;

- cold rolled;

- profile;

- cold drawn.

The installation of steel products, due to their weight, is quite complicated, but they are still used in various pipeline structures - technological and household.

According to the type of section, these types of steel pipes are distinguished:

- round;

- square;

- rectangular;

- polygonal.

Such products are interconnected: by special couplings, thread or welding. They are very durable and able to tolerate high pressure readings.

The dimensions and weight of steel pipes are presented in table No. 1.

Table 1

| Mm | Outer diameter mm | Mass of 1 m pipe, kg |

| 125 | 165 | 15,04 |

| 100 | 114 | 12,15 |

| 50 | 60 | 4,88 |

| 40 | 48 | 3,84 |

| 32 | 42,3 | 3,09 |

| 20 | 26,8 | – |

| 10 | 17 | 0,8 |

During operation, the characteristics of steel pipes deteriorate - they inevitably lose their throughput due to narrowing of the clearance. In addition, they conduct electric current, which with faulty wiring can lead to electric shock. The service life of steel products is approximately 25 years.

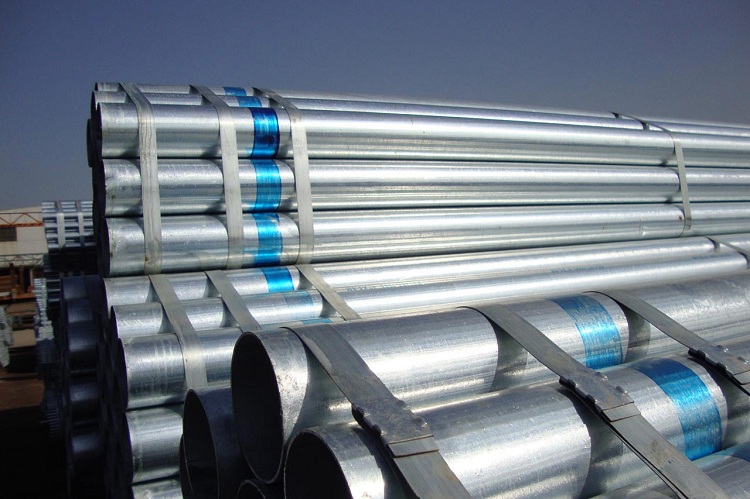

Galvanized steel

Galvanized steel parts are more reliable, but this affects their cost. They are resistant to temperature extremes and, thanks to the protective zinc layer, are resistant to corrosive influences.However, the protective layer can be damaged for one reason or another (from impacts) and then rust will appear in the places where it broke off.

Such pipes are used in cases where it is necessary to mount a solid structure that will not be subject to pressure drops and temperature surges. Galvanized steel parts are ideal for temporary structures in harsh environments.

Copper pipes

Copper plumbing is the most expensive option of all. They are distinguished by high technical characteristics: durable, resistant to corrosion and temperature extremes (indicators of operating temperature range from –200 ° С to +250 ° С). In addition, due to their appearance, they can become an interior decoration. However, the modern market can offer parts that meet the necessary technical characteristics and are cheaper, therefore, such pipelines are mounted solely because of their aesthetic “exterior”. The service life of copper alloy products can reach 50–100 years.

Important! When installing a copper pipeline, it should be borne in mind that copper is incompatible with connectors from other metals. Therefore, fittings for copper structures must be made of the same material.

The dependence of the wall thickness of copper pipes on the diameter can be found by studying table No. 2.

table 2

| Mm | Wall thickness mm |

| 10–28 | 1 |

| 35–54 | 1,5 |

| 54–89 | 2 |

| 89–108 | 2,5 |

| 108 | 3 |

Components for such products are quite rare and sometimes they are difficult to find on sale (especially for non-standard designs). Installation of a copper pipeline is an expensive and difficult task.

It is also worth noting that the strength of such communications is poor. The copper part is easy to mash, thereby narrowing its clearance. Therefore, the operation of such pipelines should take place without risk of mechanical damage.

Cast iron pipes

Cast iron pipelines are resistant to corrosion, however, they are not as durable as steel. Among other disadvantages, they are very heavy and require reliable fasteners for their installation.

From cast-iron parts, water structures are installed, as well as heating and sewer communications. To date, there are three types of cast-iron pipes that differ from each other in terms of strength:

- black cast iron;

- gray cast iron (more durable);

- products from ductile iron with spherical graphite (VChShG).

Details cast from gray cast iron have good strength and have rough walls. Ductile iron pipes are highly durable and can withstand heavy loads in the soil or under the road surface. The diameter of cast iron products varies from 50 to 1000 mm. The service life of such pipes is 20-50 years.

There are such types of pipes made of cast iron according to the method of connection:

- bell-shaped;

- products that are joined using chasing.

Sometimes, to increase the anti-corrosion characteristics, cast-iron pipelines are coated with a protective coating of varnish or bitumen.

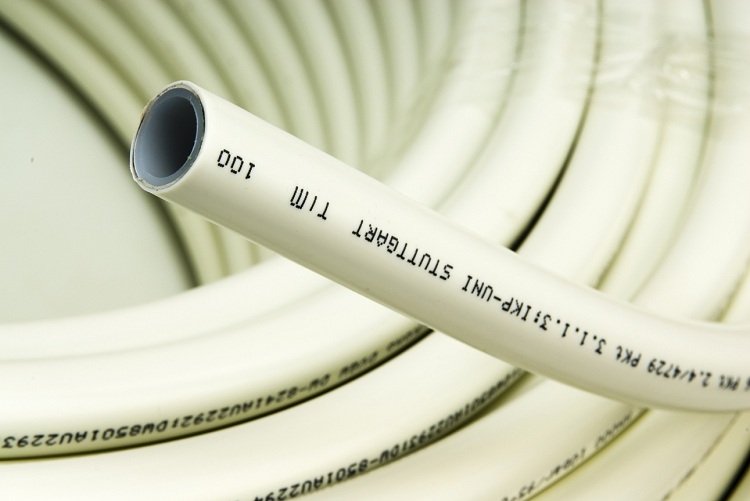

Plastic pipes

Products that are manufactured as a combination of metal and plastic are very popular and have excellent quality characteristics. Installation of a pipeline of metal-plastic pipes is perhaps one of the simplest. Anyone who can carefully study the rules and installation tips, as well as acquire all the necessary materials and tools, can assemble such a construction with their own hands.

The negative qualities of these pipes include the possibility of leakage at the joints and poor thermal stability. In addition, metal-plastic communications are not fire resistant.

Note! A metal-plastic product consists of layers that during operation during temperature changes can delaminate and form a gap between the connecting part and the pipe.

The operating temperature for metal-plastic parts is 80–100 ° C. Various pipelines are made of such pipes: hot and cold water pipes, heating, communications for underfloor heating. They are resistant to aggressive chemicals and have anti-corrosion properties, and the metal layer increases the strength of the structure. The operational life of such products is approximately 30–35 years.

The connection of such pipes, as a rule, is carried out using special fittings. All fittings by type of connection are divided into:

- threaded;

- press fittings.

Today, press fittings are considered to be popular connecting elements for metal-plastic communications, with which you can mount a strong and reliable connection.

Plastic pipes

Plastic is the generalized name for pipes made from various polymers. Each type of such products has its own characteristics and properties.

Polyethylene. There are such types of pipes made of polyethylene:

- low pressure polyethylene (HDPE);

- high pressure polyethylene (LDPE);

- stitched polyethylene.

Polyethylene parts do not tolerate high temperatures well (except for cross-linked polyethylene), therefore, they are most often used for installation of cold water structures or sewers.

The positive characteristics of products from this material include:

- ease of installation;

- anticorrosion;

- a light weight;

- long service life (up to 50 years).

The diameter of polyethylene pipes ranges from 10 to 1000 mm. They are able to withstand pressure from 2.5 to 16 atmospheres, and in some cases more. Operating temperature can be from –40 to +40 ° C.

Such pipes are connected by welding or electrofusion. The latter is equipped with a special wire that heats the junction and forms a strong grip.

PVC A common type of pipe that is used in the following areas: sewerage, water supply, drainage systems. The diameter of such products can be from 16 to 500 mm, and the operating temperature reaches +90 ° C. For hot water systems, parts with a cross section of 16 to 50 mm are used.

Pressure that can be carried during operation PVC pipesranges from 6 to 46 atmospheres. In addition, polyvinyl chloride is fire resistant, so it is often used to protect electric cables and wires.

The ease of installation allows you to mount PVC products quickly, without the use of any professional equipment. Joining of PVC parts with each other takes place through special fittings. The operational life in some cases reaches 50 years.

Polypropylene The most common type of plastic pipe and generally at present is the most popular type of all pipes for water systems. Their popularity is due to many positive characteristics, but above all, it is easy to install. Use such pipes in:

- hot and cold water systems;

- heating systems;

- when laying a warm floor;

- in sewer communications.

According to the diameter range, polypropylene pipes can be from 16 to 125 mm. The assembly of the PP pipeline is by welding. Each pipeline category has its own pipe type (PN10, PN16, PN20, PN25). A digital indicator indicates what pressure a particular product is designed for. That is, the PN20 pipe marking tells us that such products are designed for systems with an operating pressure of 20 atmospheres.

Important! As a rule, pipe signs are applied to the outer surface of the product (no closer than 2 cm from the edge). Pipes marked PN10 are used for systems in which the working environment is cold water. Products marked as PN20 are used for communications with hot and cold water, and PN25 - for heating and hot water.

The installation of polypropylene pipes is carried out by butt or socket welding using a low-temperature soldering iron. The service life of polypropylene parts when used correctly is 50 years.

Pipeline classification

Today, there are many types of pipelines. All of them are divided into groups according to the following indicators:

- on a portable substance;

- material

- performance characteristics;

- environmental aggressiveness indicator;

The substances transported are: oil and gas pipelines, steam pipelines, water pipelines, etc.

According to the production materials there are:

- steel;

- copper;

- cast iron;

- metal-plastic;

- plastic;

In addition, there are concrete pipelines, as well as structures made of heat-resistant glass.

In terms of pressure in the system are found: vacuum, low pressure, high pressure and pressureless. By temperature there are: cold (below zero), normal (from 1 to 45 ° C), hot (from 46 ° C and above).

In terms of the aggressiveness of the transported substance, there are three types of pipelines:

- for non-aggressive environments;

- slightly aggressive;

- moderately aggressive.

In addition, it is worth remembering that the designations on the drawings of pipelines according to GOST include a simplified image of the structure and an alphanumeric record that indicates the type of medium being transported. Designations of any types of pipelines should occupy a minimum of space and be clear.