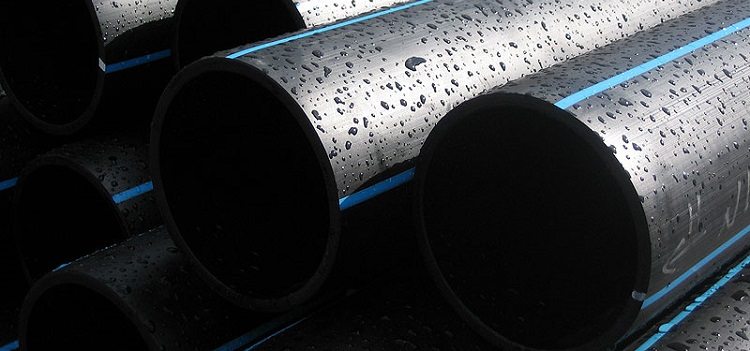

Polyethylene pipes are widely used in the installation of modern external and internal sewer systems. Compared with analogues from other materials, they are cheaper, have more favorable technical and operational characteristics, and are easy to install. Polyethylene production is based on the polymerization of gaseous ethylene in the presence of catalysts at high temperature and pressure.

Content

Features of the production of polyethylene pipes

Sewer polyethylene pipes are produced by extruding heated plastic through a round hole, followed by calibration in a vacuum chamber, cooling and marking. In this assessment are subject to such indicators of product quality:

- the appearance of the inner and outer surfaces;

- the value of elongation at break;

- variation of the length of the polyethylene pipe when heated;

- resistance to internal pressure.

High pressure polyethylene (LDPE) has a low density, it requires high temperature and pressure to produce it. Low-pressure polyethylene (HDPE) is a high-density structure, produced at a temperature of 120 to 150 ° C and a pressure of 100-2000 kPa. For the manufacture of polyethylene pipes for sewage, both types of this material are used. For hot water supply and heating, cross-linked polyethylene is used. It is a high molecular weight compound and differs from HDPE and LDPE by a melting point of 360-430 ° C and higher strength. Such pipes have good sound absorbing properties.

Important! The polyethylene pipe for the external sewerage is unsuitable for hot water supply systems.

When buying a pipe, be sure to pay attention to the marking of the pipe, which contains all the information about the product.

Types of pipes and their marking

- LDPE pipes are characterized by high elasticity, mechanical stability and strength under tensile stress. They consist of three layers and are suitable for transporting liquids with a pressure of up to 3 MPa.

- Polyethylene pipes for pressure sewer. Are made according to GOST 18599 - 2001. "Pressure pipes made of polyethylene. Technical conditions. "

- HDPE pipes for sewage are very durable, able to withstand temperatures above -50 ° C. Crimp fittings are often used to connect.

- Corrugated polyethylene pipes are used for outdoor sewage. They are plastic and have a two-layer structure: the outer layer provides strength, the inner - unhindered flow of fluid. Often made of polyethylene type PE-80 or PE-63, characterized by resistance to chemical influences. A characteristic feature is the ability underground styling of these pipes to a depth of 1-20 m. The production of corrugated pipes is not regulated by standards and is carried out in agreement with the customer.

Polyethylene products for internal and external sewerage have a symbol of the form:

- abbreviated name of the material;

- standard size ratio (SDR);

- nominal outer diameter (mm);

- nominal wall thickness (mm);

- appointment;

- the standard by which the pipe is made.

Marking is applied at intervals of up to 100 cm, indicating the trademark and the date of manufacture of the pipe.

Standardized pipe specifications

The manufacture of polyethylene pipes is regulated by GOST 22689 "Sewer and shaped pipes for polyethylene pipes" with the number of standards group: 0 - general technical conditions; 1 - assortment; 2 - design.

According to the document, polyethylene sewer pipes have certain parameters.

Table 1

| Nominal diameter mm |

Nominal thickness walls, mm |

Mass of 1 m pipes, g | ||

| PND | LDPE | PND | LDPE | |

| 40 | 2 | 3 | 228 | 322 |

| 50 | 3 | 3 | 423 | 409 |

| 90 | 3 | 4,3 | 782 | 1068 |

| 110 | 3,5 | 5,2 | 1117 | 1580 |

According to the diameter of the pipes are selected fitting. The standardized pipe lengths are 200, 300, 550, 600, 800 cm, but non-standardized lengths are allowed. The industry usually produces pipes with a length of 600-1200 cm. The standard gives the diameter and length of the sockets with which to produce pipe connection, the sizes of crosspieces, couplings, tees, etc. are regulated. The maximum working temperature for polyethylene pipes is 40-50 ° C. A short-term temperature increase of up to 60 ° C is possible.

Important! The standard does not recommend connecting HDPE sewer pipes with LDPE by welding.

The symbol for polyethylene pipes includes: letter abbreviation TK (sewer pipe), diameter in mm, length in mm; name of the material of manufacture, production standard.

Mounting Features

Polyethylene pipe joint happens welding, coupling and bell-shaped. The welding connection is made by a special device consisting of several bushings and a heating plate. The ends of the pipes fixed in a certain position are melted and pressed against each other. The second type of connection is made using sliding couplings with rubber cuffs. This method is most common when installing an external sewer for connecting corrugated pipes. The bell-shaped connection is used during the installation of the internal communications network and is made in the following order:

- according to the project, the required number of polyethylene pipes for sewage and fittings is selected;

- the chamfer is removed, the presence of a burr is checked;

- the pipe is inserted into the socket, leaving a gap of up to 10 mm.

Compression fittings are used to connect polyethylene pipes of small diameters (up to 5 cm). Achieving tightness between the parts is possible by pressing on the tube of the crimp ring. The fittings are corrosion resistant, can be reused, provide a reliable high-strength connection. They include a housing, a sealing ring and a clamping ring, a press-in sleeve and a nut cover. Thanks to the special material for the manufacture of the clamping ring, the crimp fittings withstand heavy loads along the axis and vibration during water hammer.

The method of connecting polyethylene pipes depends on the diameter of the pipe, the location of the sewer system

The advantages of polyethylene pipes

Polyethylene pipes for sewage have these advantages:

- Resistant to aggressive environments.

- Do not need special maintenance.

- Easy to install, disassemble due to its low weight.

- Resistant to water hammer.

- They are not very heavy, which simplifies the installation work.

- The price is much lower than for steel counterparts.

- Long service life.

- There is no need for cathodic protection.

- Resistant to chemicals.

- They exhibit anticorrosive and frost-resistant properties.

- They are distinguished by simplicity and reliability of the connection.

- Welding connection of polyethylene pipes cheaper than metal.

The service life of pipes for sewage PND depends on the working pressure and water temperature.

table 2

| Working pressure, MPa | Temperature ° C | Service life, years |

| 1 | 95 | 10 |

| 1 | 80 | 30 |

| 1,6 | 60 | 25 |

| 2 | 20 | 50 |

In addition, HDPE sewer pipes do not need additional waterproofing. For the normal functioning of the outer part of the network in winter, it is enough to warm the sewer pipes with any available material.

Important! Polyethylene pipes for external and internal sewerage are sensitive to sunlight, which can be deformed by long-term exposure.

The use of polyethylene pipes is limited only by the insufficiently high operating temperature. In other operational and technical parameters, they are indispensable for installation of sewer systems.