Such qualities as frugality and economy are inherent only to man. Over the centuries, it is they who are driving technological progress and contribute to the creation of devices designed not only to make life easier, but also to use all available resources to the maximum. The cost of heating a house is rightfully considered the highest. And just the heat exchanger on the chimney pipe is one of the most affordable options for saving heat in a private building with stove heating.

To get the maximum heat from the furnace system, you can install a DIY heat exchanger on the chimney

Content

Varieties

Today there are many types of such devices. But the most popular are:

- corrugation heat exchanger;

- a heat exchanger equipped with a water tank;

- coil-shaped heat exchanger;

- air heat exchanger.

Depending on the type of coolant circulating inside the device, all heat exchangers are divided into liquid and air. The latter are most easily manufactured, but their effectiveness is poor. While a chimney with a heat exchanger, inside of which water circulates, can be used as a full-fledged heating system for a small cottage, if the supply / return to radiators is connected to the input / output of the device.

Each craftsman, creating a useful device for his needs, introduced personal ideas that contribute to the improvement of its design. The implementation of the heat exchanger on the chimney pipe according to its drawings was carried out using such components as:

- heating registers;

- collectors;

- metal tanks:

- various coils;

- radiators of domestic heating systems;

- radiators of the engine cooling system of vehicles.

Liquid heat exchanger

The standard design of this type of device looks like a metal coil, which has a high coefficient of thermal conductivity. To ensure safety and better heat transfer, it is placed in a metal casing and is well insulated with a non-combustible insulation, which is usually used as basalt wool.

Installation of the structure is carried out on the chimney section. The ends of the coil are first discharged through the body of the heat exchanger, and then connected to the heating system. An expansion tank is placed at its upper point. It is best to make a coil from a copper annealed tube. Of course, you can use such a steel element, but in order to achieve a comparable effect, then you will have to create a structure 7 (!) Times larger in size. This is due to the higher thermal conductivity of copper.

The natural circulation of the coolant through the system is as follows: the liquid is heated and, increasing in volume, rises along the coil. Then it flows by gravity through the pipe into the radiator. The cold coolant located there is forced out and, having entered the coil, it again heats up.

Important! In order for the coolant to circulate through the system, it is necessary to accurately calculate the diameter and length of the coil, withstand the inclination angles of both the supply and return, and much more.

Underestimating these calculations can lead to sad consequences. The fact that the device will not work is not so bad. Much worse is the possibility of water hammer due to boiling coolant.

Some types of heat exchangers are difficult to manufacture with their own hands so that their operation yields the desired result

The following disadvantages are inherent in this type of heat exchanger on the chimney pipe:

- complexity of calculations and manufacturing;

- the need for constant monitoring of pressure and temperature in the system;

- increased flow rate: the liquid simply evaporates from the expansion tank. When using water in the winter, when the system is not in operation, the liquid must be drained;

- the temperature of the exhaust gases is significantly reduced. And this can lead to a decrease in traction and incomplete combustion of the fuel used.

At the same time, a person who has only knowledge of the physics of the high school course and has the skills to handle the tool can make a liquid heat exchanger for the chimney with his own hands.

Air heat exchanger

A device of this type usually consists of a metal case, inside of which several nozzles are mounted - input and output. At the heart of its functioning is the principle of convection. The cold air entering the nozzles heats up and enters the heated room through the top of the heat exchanger. Such a technical solution provides an opportunity to reduce fuel consumption by a factor of 2-3 without reducing the efficiency of the heat generating device.

To make such a device on your own will not be any difficulties. For this, metal pipes of various diameters, a grinder and a welding machine will be needed.

For the manufacture of an air heat exchanger, a metal sheet, pipes of different diameters and an iron container of a suitable size are needed

Before starting work, stock up on such material:

- a piece of pipe with a diameter of 50 millimeters;

- a pipe length of 2.4 meters with a diameter of an inch and a quarter;

- metal sheet 350 × 350 × 1 (unit of measurement is millimeters);

- A 20 liter bucket of engine oil or a metal tank.

The manufacturing procedure is as follows:

- cut circles from a sheet of metal. They will be used as end parts. It is necessary that their diameter correspond to the value of this parameter of a previously prepared container;

- in the center of each circle, cut a hole for the central 50 mm pipe;

- on both parts around the central hole evenly mark the points at which cut 8 openings for pipe sections with an inch and a quarter diameter;

- cut this pipe into 8 segments with a grinder. That is, the length of each tube should be 30 centimeters;

- using a welding machine, attach a piece of pipe with a diameter of 50 millimeters to the central hole, and the elements obtained in the previous step to the side holes;

On a note! By following the above steps, you will create the core of the heat exchanger. The next stage is the manufacture of its body.

- Use a grinder to cut the bottom of a previously prepared metal tank.

- on its sides in the center, cut a hole with a diameter equal to the cross section of the chimney pipe.

- by welding, attach pipes of a suitable size to the holes made.

- put the body made by this method onto the core and weld to it.

- cover the finished product with heat-resistant paint.

- after the paint has dried, install the heat exchanger in the chimney.

Features of the heat exchanger on the chimney pipe in the bath

By design, such devices are divided into two types - built-in and attached to the pipe.The execution in the second embodiment was called the samovar type heat exchanger.

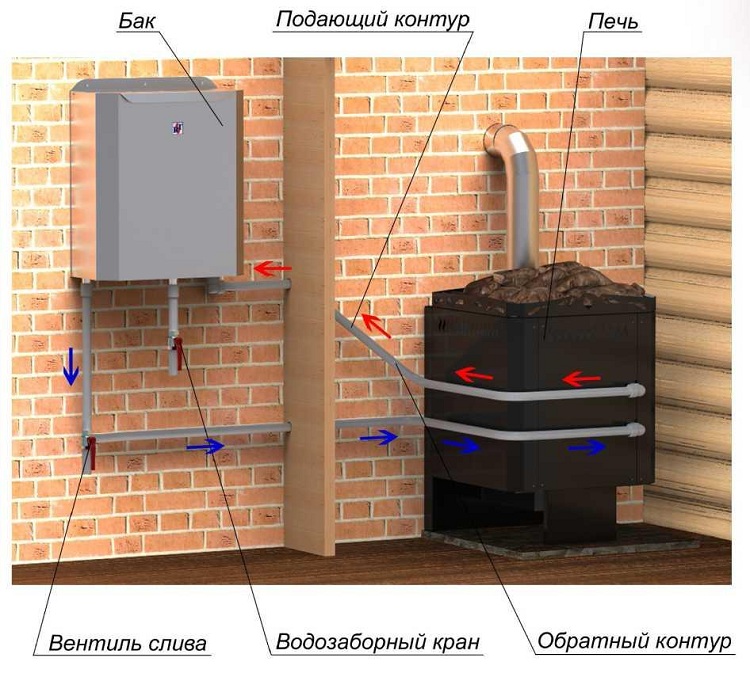

The built-in heat exchanger includes a small tank with a capacity of, as a rule, up to 5 liters, installed between the furnace and the casing of the heat generator. Contact with open flames must be completely avoided. By means of pipes, a tank is connected to the built-in heat exchanger, the volume of which can reach 100 liters. When the heating system heats up, hot water rises up the pipe, and the cooling water flows through the other pipe back into the heat exchanger. So in the external tank the required water temperature is maintained.

A samovar-type heat exchanger is nothing more than a sealed container that surrounds the upper chimney. According to experts, this heating option is preferable. They explain this by the fact that during the heating process the heat of combustion products moving through the chimney is used. And it is also important that if we compare the volumes, then the value of this parameter of the heat exchanger attached to the pipe is greater than that of a built-in product.

Sauna stove with heat exchanger - advantages and features of operation

We highlight the main advantages of furnaces in a bath with a heat exchanger.

- The bathing system of this design solves two problems at once - it heats the rooms of the dressing room and the steam room, and also heats the water.

- The tank must be located in the room closest to the steam room.

- Despite the relatively low cost of furnaces with a heat exchanger for a pipe in a bath, they are characterized by a large operational resource due to the use of high-quality materials in the manufacture.

- Due to equipping the firebox of a modern furnace with refractory glass, you can enjoy the flames and control the combustion process.

- Unpretentiousness of the system in care;

- Attractive appearance.

- The small dimensions of the furnace with a heat exchanger on the pipe in the bath help save space in the steam room.

- The power of such a system is enough to quickly warm the steam room to the desired temperature.

The design of the sauna stove with a heat exchanger is not difficult, and the tank can be placed in a room adjacent to the steam room

Security issues for every person come first. This factor requires the system to operate correctly. It is impossible to fix the pipes connecting the tank to other parts of the structure motionless to the wall, since their linear parameters change when heated.

Advice! Sealing threaded joints of a structure should be carried out using gaskets capable of withstanding high temperatures.

The volume of the water tank should be selected taking into account the fact that its heating should be carried out for two hours from the moment of ignition in the fuel furnace. Otherwise, the water will simply turn into steam.

The power of the created heat exchanger on the chimney pipe in the bath should not affect the functioning of the furnace itself. At the same time, the level of permissible power reduction should not exceed 10%. When the system is heated to high temperature, it cannot be filled with water.

Other durable and easy options

The design was considered above when the coil of the heat exchanger is placed in a metal case. But there is a simple and practical option for using such an element. The chimney is wrapped in a copper pipe. It warms up all the time, due to which the temperature of the air passing through it increases markedly over a short period of time. Such a spiral is welded to the chimney by semi-automatic welding or an argon torch. The tin used as solder must first be degreased with phosphoric acid. The connection will be durable and reliable.

Home craftsmen often create a heat exchanger from corrugated pipes. In this case, the chimney is wrapped round with three aluminum corrugations. The air present in the pipes will warm up from the walls of the chimney, and the owner of the house will just need to direct it to the desired room. To make heat removal more productive, wrap corrugated spirals with cling film.

In the section of the chimney passing through the attic, you can install a heat exchanger that works in the same way as a bell furnace. The principle of operation of such a system is based on the laws of physics: air heated to a high temperature rises, and when it cools, it falls down. This option is suitable if the chimney in the house is made of metal, which is most heated at the level of the second floor. The risk of burns or fires is reduced with a cap.

To accumulate heat, some home craftsmen around such a heat exchanger install a grid with stones on the pipe, and, having ennobled the stand, bring even more comfort to the room. This option not only warms, but also soothes. And the principle of operation of this design does not allow heating of pipes above 170 degrees.

Important! Additional security is created by the fact that the hottest place is near the gate.

Installing a heat exchanger on the chimney will allow you to use heat more efficiently. But, acquiring a specific model of such a device, it is necessary to correctly select its operating modes and power. Otherwise, you risk violating the operating conditions of the heat generating unit itself.