One of the most important parts for any home is the boiler chimney. Its main purpose is the removal of carbon monoxide, which can cause severe poisoning. Improper installation of the chimney can lead to smoke or even a fire. Installation work can be done with your own hands with the fulfillment of all necessary requirements and rules. Modern chimney ducts are structurally complex systems that require careful selection and high-quality installation.

Content

Types of chimney ducts

The main types of chimneys are:

- steel (single-circuit, double-circuit);

- brick;

- modular (ceramic, galvanized, stainless steel).

To carry out the installation of chimneys in a boiler room, it is necessary to have information about the temperature of the exhaust gases, the type of heating device, its location and efficiency. The temperature of the gases can reach hundreds of degrees when using the device solid fuel. Such values and loads can be carried by chimney constructions made of ceramics and heat-resistant steel.

Not always the installation of the chimney is limited to simply bringing the pipe to the roof. The design features of the houses require the use of additional parts of the smoke exhaust system to go around obstacles, pass through floors, etc. For these purposes, a knee, tee and adapter pipe are used. Pipes are attached with brackets.

Currently, metal pipes are most often used for installing a chimney. The easiest is to install a horizontal chimney. To do this, just make a hole in the wall of the boiler room. There are also flexible pipes for chimneys.

Features of a brick chimney

The advantages of a brick chimney are mechanical strength, durability of heat transfer, fire safety. However, such designs are not without drawbacks. The rectangular section of the brick chimney impairs draft. Depressions and protrusions on the inner surface reduce the speed of the gases and lead to the deposition of combustion products, which over time destroys the structure of the chimney. Of all the types, the brick structure is the heaviest and requires the greatest labor costs during installation and dismantling of the boiler chimney.

Important! It is not recommended to use galvanized steel for the chimney, since the zinc layer quickly burns out and the smoke duct remains unprotected.

The work of modern heat generators is based on the burning of natural gas or liquid fuel. When they are used, condensation appears on the inner surface of the chimney, which leads to the destruction of the brickwork. To prevent this, additional waterproofing is used, but it is better to resort to the installation of metal chimneys.

A variety of pipe materials

Advantages of the steel single-circuit smoke exhaust channel are:

- low weight;

- round section;

- resistance to corrosion;

- smooth inner surface;

- high speed and ease of installation.

In the absence of thermal insulation in these pipes, the flowing gas is quickly cooled, which leads to the formation of condensate. However, the choice materials for thermal insulation of metal pipes very wide, so the problem can be easily solved. The service life of such chimneys is 10-15 years.

Double-circuit designs incorporate two steel pipes with a non-combustible seal between them. This structure allows you to maintain the temperature of the flue gases, which increases their speed through the channel, to prevent the formation of a large amount of condensate and conduct external installation of a chimney.

Ceramic chimneys include such components:

- ceramic pipe;

- thermal insulation from non-combustible material;

- protective box made of aerated concrete.

Such designs are distinguished by reliability and durability. The use of flexible polymer flues is limited by the temperature of the flue gases. Such pipes are characterized by low heat resistance, low mechanical strength, lack of insulation and are applicable only to high-efficiency gas heaters and boilers.

Possible application corrugated steel chimneysDIY installation and maintenance are very simple. Such channels have a short service life.

Chimney height and diameter requirements

Chimney installation height must satisfy the following requirements:

- When the pipe is removed above the flat roof, its protrusion above the surface should be more than 50 cm.

- If the roof covering is made of materials that are highly flammable, then the pipe is discharged to a height of more than 1 meter.

- If the distance from the roof ridge to the location of the chimney is in the range of one and a half to 3 meters, then the pipe should be higher than the ridge.

- If the distance from the chimney to the roof ridge is more than 3 m, its height should be higher than the beam drawn down from the ridge at an angle of 10 ° to the horizontal.

- If the roof is made of combustible materials, then the pipe should be located 1-1.5 m above the ridge.

All these requirements must be met, otherwise damage to the roof and even its fire are possible.

Important! The choice of the type of cross section for the chimney of the boiler room is determined by the norms and depends on the capacity of the heat generator.

| Heat generator power, kW | Section parameters, mm |

| less than 3.2 | 14 x 14 |

| 3,2-4 | 14 x 20 |

| 4-8 | 14 x 27 |

The circular cross-section should correspond to the rectangular area for a certain power.

Norms and rules of installation

The installation of boiler chimneys is subject to certain rules. The gas boiler must only be equipped with a vertical chimney. Possible deviation from the axis to the side by a maximum of 1 m or 30 °. Such a shift is permissible at a distance of not less than half a meter from the bend to the boiler chimney. The minimum length of the chimney is 5 m.

Important! Do not pass uninsulated pipes through floors.

When installing a chimney pipe with your own hands, their diameter and height are important. The higher the pipe, the better the draft. If the ratio of height and diameter is not correct, the chimney may lose functionality due to loss of draft.

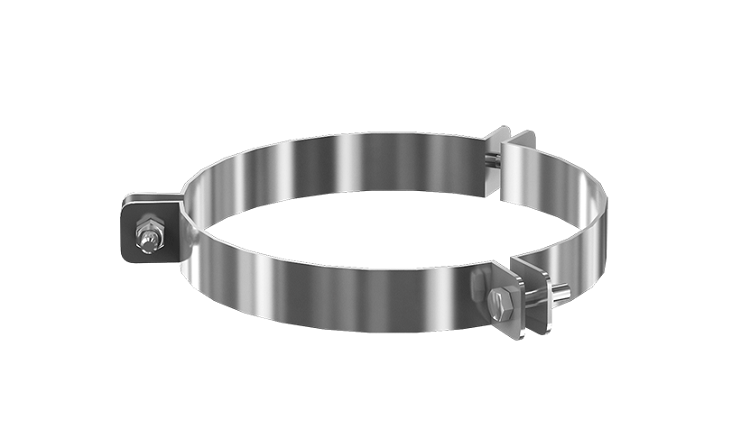

It is forbidden to install joints inside the ceilings, since they must be provided with quick access if necessary. The pipe must be secured along its entire length every 1.5-2 meters. To fix the chimney on the roof, which protrudes 1.2 m or more, special extensions are used.

Chimneys of boiler rooms are installed in accordance with fire safety regulations. To do this, the wooden parts and surfaces that border the installation site must be treated with special substances.

Galvanized iron is required to cover the outside of the pipe.Do-it-yourself chimney options depend on the characteristics of the boiler room and the installation location of the equipment. An external flue duct typically includes a connecting duct, inspection holes, sections, and a wall bracket. Such pipes must be insulated. Bends should be avoided since soot will accumulate in such places.

To install the chimney of the boiler room, you will need such tools and materials:

- trumpet;

- grinder and scissors for metal;

- roulette, level;

- a set of locksmith tools;

- clamps and brackets;

- insulation;

- sealant, self-tapping screws, etc.

An internal chimney is installed inside the building. Installation is carried out with the device of a protective casing, support and cutting. About 60 cm before the floors, it should be insulated. It is not necessary to insulate such a channel, except for the part passing through the unheated attic. Pipes are located along the internal partitions of the building or walls, which should not be built from combustible materials.

An external chimney is easier to install in a finished house, while the integrity of the ceilings is not violated.

The installation process of the chimney duct

Installation of chimneys is produced from the bottom up. First, the transition from the chimney to the boiler is selected. The insertion of the connection should have a depth of more than 5 cm. It is better to leave a gap of 5-10 mm around the perimeter, which will provide some freedom of action during installation.

In the wall, cutting is done to install the sleeve, which is made of a metal (steel) pipe. It is installed on the solution and protects the smoke channel from the load of the load-bearing wall. A gap of 40-50 mm is left between it and the sleeve, which is then sealed with a solution. This design will facilitate the dismantling of chimneys if necessary.

Brackets for fastening pipes can be made by yourself or buy ready-made. The fastening must be reliable and high-quality and depends on the material of the walls. The wiring can be bricked, leaving revisions. At the bottom, the plug of the vertical section of the chimney is equipped with an opening for condensate drain with a diameter of 5-10 mm.

The links of the metal pipe are assembled, sequentially inserted into each other. Such a chain protects the structure from moisture entering the insulation.

Important! For additional moisture protection, special sealants with an operating temperature of about 103 degrees are used.

The horizontal sections of the pipe are limited to a length of 1 m and should not touch any communications. The section of the chimney that faces the street should be protected from the wind by fixing.

Chimney insulation and cleaning

Insulation of the boiler chimney affects the draft, which deteriorates when the gases cool. For these purposes, you can apply basalt wool. It has good refractory properties, but requires isolation from moisture. Basalt wool is wrapped around the pipe several times and secured with clamps.

During the operation of the chimney, carbon-containing combustion products may settle on its inner surface. They must be removed periodically. Do it yourself repairs and pipe cleaning is carried out using mechanical, physical and chemical methods.

Do-it-yourself mechanical cleaning is done if the soot layer is more than 3 mm. For her, the cargo is used on a cable with a ruff, which must be thrown from above into the chimney. If the blockage does not break through, then the part of the chimney where it formed is disassembled.

Do-it-yourself dry cleaning involves the use of substances that corrode soot. Professional work is carried out using spray guns and reagents, after exposure to which the soot lags behind the walls of the chimney and crumbles. The effect of this procedure lasts 3-4 months.

Thus, the chimney must be functional, efficient and safe, and chimney pipes - reliable and high quality. Properly made do-it-yourself installation work will ensure a long life of the heating system at home.