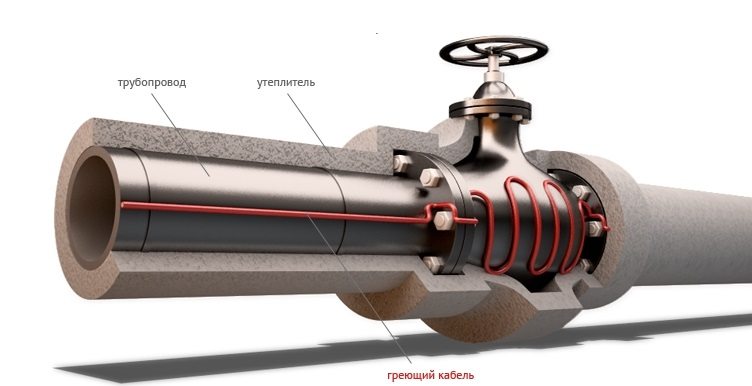

To prevent the failure and freezing of pipes in the winter, a special cable is used. A feature of the self-regulating heating cable for pipes is the ability to heat or cool depending on the ambient temperature. No sensors or regulators are used. Most often, such a cable is used to heat pipes with a diameter of more than 4 cm, tanks, roofs, gutters, etc.

Content

The device and types of cables for heating pipes

The basis of the work heating cable for pipe heating the conversion of electrical energy into heat is laid. It is a conductor, the temperature of which rises and is given to the environment with the passage of current. The cable consists of two copper conductors (1.2 mm2 cross-section), a self-regulating conductive element, two insulating layers with a copper braid between them.

The heating cable is of the following types:

- resistive;

- self-regulating;

- with mineral insulation.

Resistive cable can have one or two wires and can be zonal and linear. It is applicable for heating pipes with a diameter of less than 4 cm. It is important to ensure uniformity of the medium along its entire length. Otherwise, overheating and system failure will occur.

The self-regulating cable for heating pipes has parallel uninsulated conductors located in a conductive matrix made of a special polymer. This material increases resistance when heated. The degree of heating of the cable is inversely proportional to the ambient temperature.

A cable with mineral insulation exhibits high dielectric properties, is resistant to ultraviolet rays and electromagnetic radiation.

Benefits of self-regulating wires

The advantages of using a self-regulating cable include:

- The ability to automatically reduce the temperature of the cable in areas with less heat transfer, without changing the temperature of other areas.

- Increased resistance to voltage drops.

- Admissibility of cutting the cable to the required length.

- The ability to overlap the cable.

Copper parallel twisted conductors provide constant voltage along the entire length of the cable. The self-regulating cable is equipped with a thermoplastic sheath that protects it from moisture and fumes. The metal braid provides grounding, shielding and protects the elements from mechanical influences.

Important! The maximum length of a self-regulating heating cable for heating pipes is limited to 60-100 m.

A self-regulating cable is able to increase power when the temperature decreases, and when it increases, it can turn off automatically. The conductive matrix provides continuous heating. This allows you to cut the cable in any place without loss of functionality.

The cost of such a cable is higher than that of a resistive one, but the operating costs are much lower. Normalization of heat generation does not allow the system to overheat.Distinguish the external installation of the cable for heating and its placement inside the pipe.

Features of internal installation

Indoor installation is used for pipelines with a diameter of up to 5 cm, to which direct access is not possible. The cable is pushed into the pipe along its entire length. For this, a special stuffing box is used, which includes 2 bushings, 2 washers and rubber seals. Installation of a cable for heating inside the pipe is subject to safety requirements:

- during entry, it is necessary to close all sharp edges and threads of fittings;

- It is strictly forbidden to allow damage to the outer sheath of the cable;

- on the outside of the pipe, the installation site of the heating system is marked;

- the meter of the wire should match the length of the pipes;

- Do not route the self-regulating cable through the stop valves.

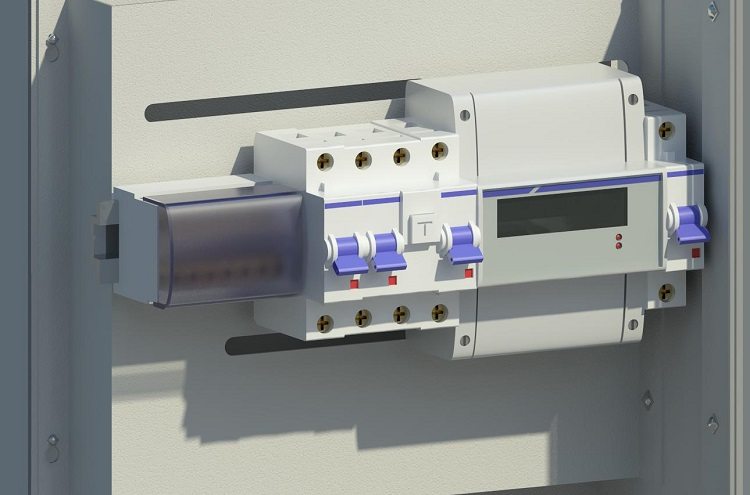

The heating efficiency is higher when placing the wire inside the pipe. Such installation is often used if the pipeline has already been commissioned and placed at a great depth underground. For this, the length of the area in need of heating is accurately measured. A short-circuit protection device must be connected to the heating cable in case of a short circuit. It is also not recommended to place heating elements inside pipes that transport drinking water.

The location of the cable inside the pipe involves the installation of an RCD for emergency power off

External installation of a wire for heating

The heating cable is usually placed on the surface of the pipe. There are several options for securing it:

- Wavy line.

- One cable is placed along the pipe in a straight line.

- Several cables are fixed parallel to each other in a straight line along the pipeline.

- In a spiral.

- Combination of previous options on individual parts of pipes, elbows, valves, etc.

During outdoor installation, the absence of mechanical damage on the outside of the heating cable is constantly monitored. It is attached to the surface of the pipe using a special sticky aluminum tape. The use of plastic tape is prohibited.

At first heating cable fixed using segments of tape that are located at a distance of about 3 dm from each other. Then the aluminum tape is allowed along the entire length of the heating wire. This ensures the strength of the connection with the surface of the pipe, a large area of heat removal, the absence of direct contact with the insulating material.

Helpful advice! The minimum diameter by which the heating cable can be bent is the sum of its six diameters.

It is recommended that plastic pipes be pre-glued with adhesive tape or aluminum foil, which will ensure an even distribution of heat over their entire surface. After fastening the cable, pipe insulation will be required with special materials to prevent heat loss.

Features of the choice of heating cables

A self-regulating heating wire with the required power should be selected based on the knowledge of such parameters:

- the material from which the pipes are made;

- insulation thickness;

- pipe diameter;

- heat losses that must be completely blocked.

The rated power of the cable is indicated on the product labeling and usually corresponds to an ambient temperature of + 10 ° C. Recommended values for the diameter of the pipes and the thickness of the insulating material are presented in the table.

Table 1

| Pipe diameter mm | Insulation thickness mm |

| 15 | 20 |

| 20 | 20 |

| 25 | 30 |

| 32 | 30 |

| 40 | 40 |

| 50 | 50 |

| 65 | 65 |

If the water supply is made of polymeric materials, then the heating cable should not exceed 17 W / m in power. Otherwise, there is a risk of failure of the drain due to overheating of the pipes.It should also be taken into account for what purpose the heating wire will be used: maintaining the required temperature and heating the pipelines (taking into account the conditions of explosive and aggressive environments), the anti-icing system for sewers or high-temperature pipelines, heating pipes in cottages, private houses.

Overview of major manufacturers

The most popular manufacturers of cable for heating pipes are the brands Raychem, Lavita, Esto and others. The largest of them is the company Devi (Denmark), which produces universal self-regulating systems with the following characteristics:

| Series | Operating temperature (maximum), ° С | Power of heating wire, W / m |

| Devi-pipeguard 33 | 85 | 31 |

| Devi-pipeguard 25 | 85 | 25 |

| Devi-pipeguard 10 | 85 | 10 |

The Devi-Pipeguard 10 series is insulated with food-grade plastic, which allows this cable to be used for installation inside pipe systems. The Esto brand is represented by wires with one or two conductors with a power of up to 20 W / m, which are used when heating sewer pipes located on the surface. The 16 W / m Lavita self-regulating cable is suitable for installation inside a pipe. Raychem wire (power 10 W / m) is used to heat water pipes.

Russian production of heating cables is represented by Special Systems and Technologies LLC.

| Series | Operating temperature (maximum), ° С | Power of heating wire, W / m |

| Freezstop | 65 | 25 |

| Freezstop simple heat | 65 | 18 |

| Freezstop lite | 65 | 15 |

| Freezstop inside | 65 | 10 |

The Freezstop Lite series is applicable for heating pipes with small diameters, Freezstop Inside (installation inside the pipe) is safe to use with drinking water thanks to a special outer shell made of fluoropolymer.

Important! Together with self-regulating cables, manufacturers recommend the use of thermostats and temperature regulators, which will allow for the control of electricity consumption.

The long-term preservation of the operational characteristics of engineering structures in the winter period directly depends on the efficiency of their heating.