Pipes for drilling are part of drilling rigs. They serve as a link between the cutting tool (chisel) and the drilling equipment. These details are needed for lowering into the well, the formation of the desired rotation and load, as well as the lifting of working tools from the bottom of the well to the surface. In addition, they supply drilling fluid, which performs the function of cooling the cutting element. Wells that are drilled using drilling equipment are classified by production products (oil, gas, water, etc.).

Content

Drill pipe features

The technology of production of drill pipes implies the absence of connecting seams. The connection of such products is carried out using locks that have special threads. In the event that they are part of the column structure, their integration among themselves is carried out using special nipples. The production of drill parts is regulated by the necessary state norms and standards. Products can be square or round.

According to the material of manufacture, drill pipes are of two types.

Steel drill pipe. The most common type. The SBT pipe may have a diameter of 34 to 168 mm. Most often, parts with a diameter of 60 mm are used in drilling operations. With their help, the so-called core drilling is carried out, in which the bit rotates very quickly, and the destruction of the rock occurs along the ring, and not along the entire face area. Steel drill pipes (SBT) are characterized by increased reliability. They can be used in diamond mining.

Light alloys. Parts made of light alloys have some structural features (for example, thickened ends and a circular cross section). Drill alloy pipes have a wall thickness of 9 to 17 mm.

Important! In the production of drilling equipment, the pressing method is used. The material that is being pressed must be heat treated in order to increase its technical characteristics. Docking of such parts is done using locks. Locks have a lighter construction.

To increase the strength, use the method by which the ends of the parts thicken. A special coupling and a locking nipple are connected to the pipe end by welding. This type of production requires increased control, all requirements and safety standards are observed. An enhanced quality monitoring system is a guarantee that the equipment will be executed efficiently and will last a long time.

One of the most important characteristics that drill pipe must have is corrosion resistance. This characteristic is due to the features of the application of these parts. The necessary anti-corrosion indicators are achieved by applying a protective layer to the surface of the workpiece, which can be represented by a colorless varnish or other substance. Thread and pipe fittings are protected with special anti-corrosion grease.

Types and characteristics of drill pipes

Drill products are divided by type of construction into:

- Whole. In the manufacture of such products, a monolithic blank with thickenings at the ends is used. Such elements are first subjected to thermal hardening, and then processed by mechanical means.

- National teams. In contrast to solid parts, prefabricated parts are hot rolled. On such parts there are special devices that are fastened at the ends of the pipes by screwing.

In addition, pipes are classified according to the material that underlies their production. As mentioned above, such materials can be steel (for the production of drill pipes sbt) or light alloys, of which light alloy products are made, respectively.

Different manufacturers of drilling tools may differ in a number of ways, but in most cases they are divided into three main types: ordinary, heavy and lead.

Ordinary

In the manufacture of parts of the usual type, only aluminum alloys and steel compositions are used. The main difference between this type is the presence of a circular cross section in the transverse direction. They are thin-walled (wall thickness ranges from 4.75 to 11 mm). For their connection with each other, specialized locks are used, which are equipped with a conical type of thread. A light alloy drill pipe (of this type) is usually subjected to a special procedure to increase strength characteristics. It is customary to thicken their ends, which helps them to function better and longer.

Weighted Drill Pipes

They are mainly made of steel and have a round cross section. The initial material is represented by forging, which is subjected to mechanical or heat treatment to enhance the quality characteristics. Such parts carry out the necessary tool load to enhance drilling. In addition, the design of this type of product has increased strength.

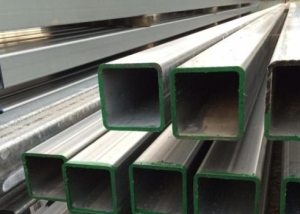

If the shape of the well is curved during drilling, weighted drill pipes with a square cross section are used. If such a part is leading, it is mounted on top of the column. Weighted products may possess, in addition to the usual types of cross-sections, also hexagonal.

The wall thickness of the weighted type of product varies from 16 to 50 mm. Their integration into the drilling structure occurs using conventional threads. Each such detail has a special marker “UBT”. As a rule, they are used under ordinary conditions. The depth at which they can carry out work ranges from 2000 to 2500 m. The outer diameter of such a pipe can be from 79 to 279 mm.

In addition, these products carry most of the load (due to the fact that they are placed at the top of the entire structure). In order to withstand it, such a drill pipe is made with reduced dimensions - it is shorter than other types.

Leading

They have a multifaceted section. Very often they are placed at the top of the column (hence the name). A distinctive feature of these products is that they have tetrahedral, hexagonal and octagonal cross-sectional views. This type of pipe is not shortened like weighted drill pipe. But, in order to withstand huge loads, their walls thicken. The thickening process occurs using various types of planting. Disembarkation can be internal, external or combined.

Important! There are inconsistent, crumbly types of rocks. These include: gravel, sand, gravel. Penetration through such soil entails rapid wear of drilling equipment. Drilling and casing products, carrying out work in such conditions, fail much faster.In addition, unstable soils may contain an increased amount of metals, and, accordingly, a high coefficient of hardness of water.

Other types of drill pipe

In addition to the above, there are other types of pipes for drilling. For example, there is a view in which locks are screwed onto a part. The ends of such products may extend outward or inward. Their length ranges from 6 to 11.5 m. They are always marked with the mark “TBVK” if the landing is inside, and “TBNK” with the outside.

Another type of pipe that is worth mentioning is parts with welded ends. They are used when passing through complex rock types.

The development of drilling equipment does not stand still and in the future new types of pipes will be invented, the functional characteristics of which will be much higher than those of the current ones. Today, the existing types of drill pipes have all the necessary properties for efficient operation in the mining sector.