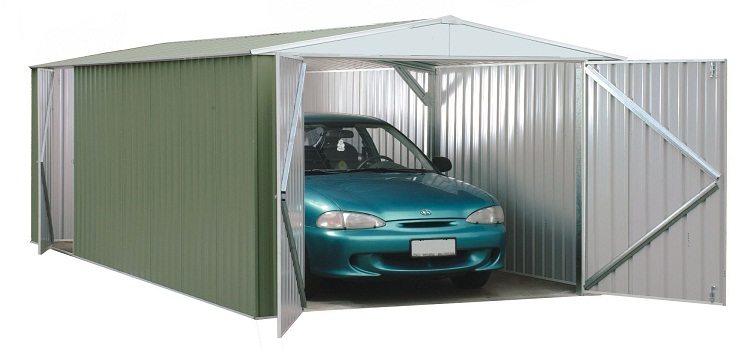

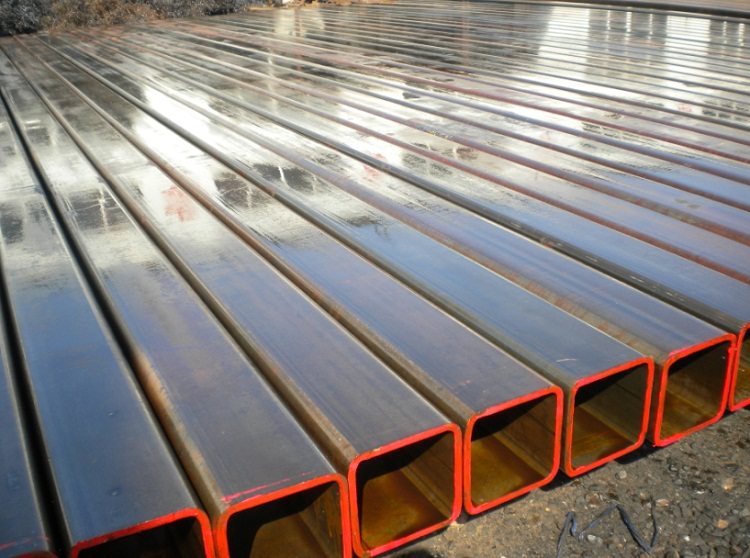

The basis of pipe garages is the frame, which is an important and very important element of the structure. It must be able to withstand heavy loads over time. Structures based on a metal frame are one of the most durable. Most often, profile pipes are used to quickly build compact buildings (garages). These products allow you to get the highest quality frame.

Content

Pros, cons of using metal for garages

The use of metal as the main material for the construction of a garage has the following advantages:

- affordability;

- lack of need for a powerful foundation (foundation);

- simplicity of work;

- sufficient structural strength;

- the ability to move the building by subsequent dismantling.

Since carcass garages from profile pipes are lightweight, less costly base options can be used for their construction. After completion of work, it is possible to avoid a large amount of construction waste.

Note! The frame made of steel products guarantees the reliability of the entire structure.

The garage from the profile pipe has negative sides, but they are conditional:

- the need for thermal insulation;

- possible rust damage.

Given the cold winters, any garages need insulation, however, compared with the overall savings in this case, the additional costs of thermal insulation materials will not be large. The second drawback is easily eliminated by the use of corrosion-resistant types of metal, painting or processing with special substances. In addition, quality ventilation in the garage will help to reduce dampness.

Steel pipes without a protective coating are susceptible to corrosion, so the garage of them will need to be painted

Stage of installation of the garage

When installing a garage from a profile pipe, the entire amount of work can be divided into the following stages:

- design (drawing);

- foundation;

- frame;

- sheathing;

- goal;

- insulation (if necessary).

At the design stage, the place of future construction is determined, the dimensions of the structure, a drawing is created. The most universal is a garage with a length of 6, a width of 3.5 and a height of 2.5 meters.

Despite the small total weight of the structure from the pipes (in comparison with analogues of concrete), the construction of the foundation is necessary. Its type is determined based on the type of soil. If the soil stability indicators are normal, then a shallow pile foundation can be used. Piles can serve as profile pipes, which must be concreted. Metal plates are welded to their upper part, on which the frame will rest. This option will save material, strength and money.

At the next stage, the garage frame is erected and sheathed. For sheathing, sheeting is used. Using roofing screws with gaskets made of rubber, sheets of material are screwed to the pipes.The frame must be sheathed on three sides. As a roof, you can also use corrugated board. At the final stage, gates are installed and, if necessary, the structure is insulated.

The primary task is to prepare the site for the garage, if necessary, the foundation is poured on it

Drawing for a garage from a professional pipe

Before starting the installation, a thorough design is necessary. It should reflect not only the design, but also the ways in which the frame will be attached to the base. For this reason, in the drawings of the garage from profile pipes, all connection points and the most accurate installation points of the stiffeners are displayed. Having a detailed plan, you can calculate the amount of required materials and tools.

Note! When creating a drawing, it is important to pay attention to the fact that the supporting profile products are solid and have the maximum possible length.

The detailed plan takes into account the method of connecting the pipes. For solid structures that are mounted for many years, it is better to use welding to fasten metal elements. When planning a collapsible garage, the places of use of fasteners (corners with suitable nuts and bolts) are applied to the drawing.

The advantage of a prefabricated building is the ability to dismantle and transport the garage, as well as expanding its area if necessary.

Necessary pipes and tools

The most suitable structural elements for the garage frame are profile products having a square section. The construction market also offers rectangular pipes, but assembly with their use will be a little more complicated. For garage racks, products with a wall size of 100 millimeters are selected. It is such profile pipes that are characterized by good strength and are able to provide high stability of the structure. As stiffeners, less wide elements with a wall of 60 mm are used.

In addition to pipes, the following tools are needed for work:

- electric drill with drills for metal;

- construction tape (10 m long);

- grinder with metal discs;

- heads and keys;

- marker.

An electric drill is necessary for making holes on the profile with your own hands. Using a grinder, you can align and cut metal pipes under the frame. Marker marks on materials. Keys and heads are used for fastening during the final assembly of the structure.

Since when working with metal small chips can form that are dangerous for the human body, especially for the skin and eyes, then, in addition to tools, it is imperative to purchase personal protective equipment (mask, glasses, tight gloves)

Possible foundation options

The foundation is necessary so that the building does not sink to the ground. The base should rise 20 cm above its surface. This will prevent water from entering the building and avoid any contact of precipitation with the walls. There are several ways to make a foundation for a frame garage:

- finished reinforced concrete slab;

- monolithic reinforced screed;

- paving slabs with preliminary concrete screed.

The use of ready-made reinforced concrete slabs is acceptable only for those who have sufficient financial capabilities to purchase it. For the foundation you will need several of these elements. Due to their severity, the delivery and installation of plates with their own hands is impossible.

Before ordering such structures, site preparation is required - leveling the work surface, specialized excavation of the pit, laying of several layers of sand and gravel.

Note! The total area of reinforced concrete slabs should exceed the area of the base of the garage frame.

With a limited budget, a monolithic reinforced screed is produced in the form of a foundation. It is perfect for this type of building.

How to create a wireframe

Upon completion of the foundation of the garage, you can begin assembling the frame. In this case, a prepared drawing is used. Profile pipes are laid horizontally on the foundation piles and welded to them. Similar actions are performed around the perimeter of the future design.

Next, vertical supports are installed and fixed. The connecting elements are pipes located horizontally. They are welded somewhere in the middle of the vertical supports. The next step is to perform the upper strapping, that is, fixing the pipe along the top of the frame racks located vertically. It is important to consider the design of the future roof of the garage.

The simplest option is a shed roof. For its implementation, one of the sides of the frame is lengthened. Next, on the horizontal profile pipes, products that perform the functions of the bearing are laid and welded from above. It is important to consider that unprofessionally welded elements can lead to structural failure, so in such cases it is better to use screw connections.

Additional garage installation work

If the garage is built only to protect the car from rain, then the work ends with the installation of the gate. However, when it is necessary for work, the room should be insulated. For this, a layer of foam boards is laid on the inside. The material is moisture resistant and is not afraid of temperature changes. Greater strength can be achieved by closing the insulation with sheets of corrugated board.

Also, to save space, experts advise using special materials with a reflective coating on one side. Such elements will avoid overheating the garage in the summer. If the region is characterized by cold winters, then a stove is installed in the garage, which has high productivity and low consumption.

Note! In this case, it is very important to make a chimney for the removal of combustion products to the outside.

Sometimes it is necessary to install additional sound insulation. However, modern materials having similar properties are quite expensive. Particular attention when installing a garage should be given to its doors. They are clearly set in level so that in a free state they do not arbitrarily move (close or open) under their own weight.

For the garage, you can choose any type of gate, the most convenient will be lifting or rolling type

Some aspects of the design of garages

There are two ways to create a wireframe:

- in place;

- modular assembly.

On-site assembly is usually used when work is done without helpers. In the second embodiment, each of the walls of the garage with stiffeners is separately assembled on a flat surface. Then the finished modules are installed on the foundation and connected to each other.

If the plan provides for a gable roof, then each element (usually 2-4 pcs.) Is also made separately and installed after assembly of the frame. There are several types of gates that can be used for garages:

- sectional;

- roller shutters;

- swinging;

- lifting and swiveling.

Installing the gate is much easier before forming the outer skin. It is also important in the drawing to provide for a small release of the roofing material beyond the walls of the garage. This is necessary so that melt or rain water does not drain onto the foundation along the walls. On the edge of the roof, it is recommended to install special ebbs.

External cladding can be performed not only with corrugated board, but also with siding panels. For their installation, sheathing of the garage frame with OSB boards is necessary.They will become not only the basis for the cladding material, but also provide additional sound and thermal insulation.

Installation of a garage from profile pipes can be performed without the involvement of specialists. Before starting work, it is important to clearly determine the purpose, structure of the structure, as well as a set of necessary materials and parts.