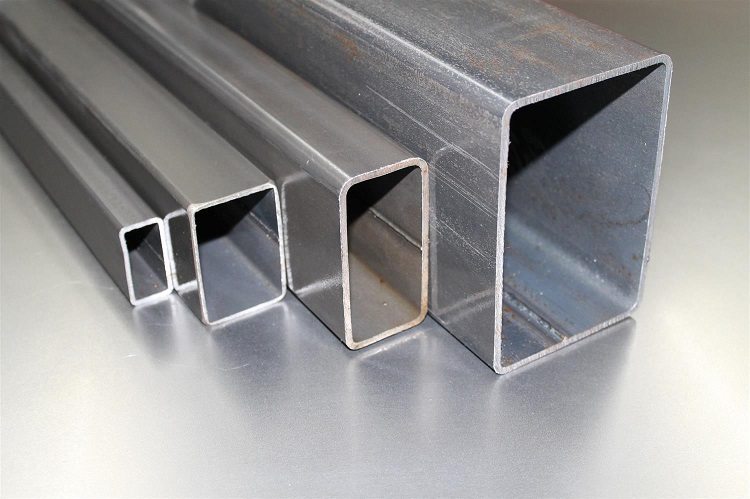

The aluminum profile pipe is a hollow metal structure that is produced in the factory. The cross-sectional shape of such products is rectangular or square. Profile pipe is widely used in various industries. A diverse assortment and unique technical characteristics explain the wide distribution of these designs.

Lightweight but durable structures for domestic and industrial use are created from aluminum shaped pipes

Content

Product standardization

The characteristics and production of rectangular shaped pipes are regulated by several documents. The product range is certified in accordance with GOST 22233 and standard 8617-81. Document 22233 gives the characteristics of profiles made of aluminum alloys by pressing (hot), which are intended for use in translucent structures of structures and buildings.

Also an important document, which contains the classification of aluminum products, technical requirements, assortment, maximum size deviations, conditions for acceptance and testing of pipes, is GOST 18475, approved in 1982. This standard extends to cold-deformed structures intended for export and national economy.

There are thin-walled (with a wall up to 0.05 * 100 mm) and thick-walled (with a wall over 0.05 * 100 mm).

Pipe classification

Standard 18475-82 gives a classification of products. So, an aluminum pipe can be assigned to one of the groups according to the following criteria: cross-sectional shape and material condition.

Note! According to the shape of the section, a round, rectangular, square and shaped pipe is distinguished. Conditional reductions of KR, PR, CV and FS, respectively.

Material condition classifies pipes into:

- caked;

- annealed;

- hardened and aged in a natural way;

- hardened and aged artificially;

- after hardening, caked and aged naturally;

- after hardening, caked and aged artificially.

Conditional reductions, respectively, H, M, T, T1, TH and T1H. The aluminum structure is made of annealed and cured of alloys AB, D1 and AMg1, and naturally hardened and aged - from D1 and AB.

Aluminum alloys for manufacturing a profile pipe

The rectangular aluminum construction is made of aluminum and its various alloys. The chemical composition is regulated by GOSTs:

- 4784-74 for D1, AB, AD31, AMg1, AMTSS, AMts;

- 11069-74 for the A5.

Pipes are made from different alloys, the composition of which is clearly regulated by accepted standards.

The characteristics of alloys of grades 1955 and AMg0.7 are regulated by separate regulatory and technical documentation. By agreement with the consumer, a rectangular pipe can be made of aluminum grades A85 and A8 according to document 11069-74.

The composition of the resource materials for the manufacture of products (according to the standard 4784) is given in the table.The numbers in the cells are the mass fractions of the elements, which are expressed in%. Each value must be divided by 1 thousand.

Table 1

| Mark | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other items | Al, not less |

|

| Each | Amount | ||||||||||

| AD0 | 250 | 400 | 50 | 50 | 50 | — | 70 | 50 | 30 | — | 99500 |

| AD1 | 300 | 300 | 50 | 25 | 50 | — | 100 | 150 | 50 | — | 99300 |

| AMC | 150- 350 |

250-450 | 100 | 1000- 1400 |

50 | — | 100 | 100 | 50 | 100 | The rest is new |

| AMC | 600 | 700 | 200 | 1000- 1500 |

200 | — | 100 | 100 | 50 | 150 | |

| AD31 | 200- 600 |

500 | 100 | 100 | 450- 900 |

100 | 200 | 150 | |||

| AMg1 | 300 | 700 | 200 | 200 | 500- 1100 |

100 | 250 | — | |||

| AB | 500- 1200 |

500 | 100- 500 |

150- 350 |

450- 900 |

250 | 200 | 150 | 50 | 100 | |

| D1 | 200- 800 |

700 | 3500- 4800 |

400- 1000 |

400 | 100 | 300 | 150 | 50 | 150 | |

Alloy D1 additionally contains Ti + Zr with a mass fraction of 0.2%. The chemical composition of the alloys according to GOST 11069 is given in the table. All values are given in% and indicators must be divided by 100.

table 2

| Mark | Si | Fe | Cu | Zn | Ti | Other mixtures (each separately) | Al no less |

| A5 | 25 | 30 | 2 | 6 | 2 | 3 | 9950 |

| A85 | 6 | 8 | 1 | 2 | 0,8 | 2 | 9985 |

| A8 | 10 | 12 | 1 | 4 | 1 | 2 | 9980 |

The main properties of products

Aluminum pipe has a number of very important characteristics that make it actively in demand in various fields. The most important property of these structures is strength, high reliability and corrosion resistance. The latter quality eliminates the need for additional external insulating coatings.

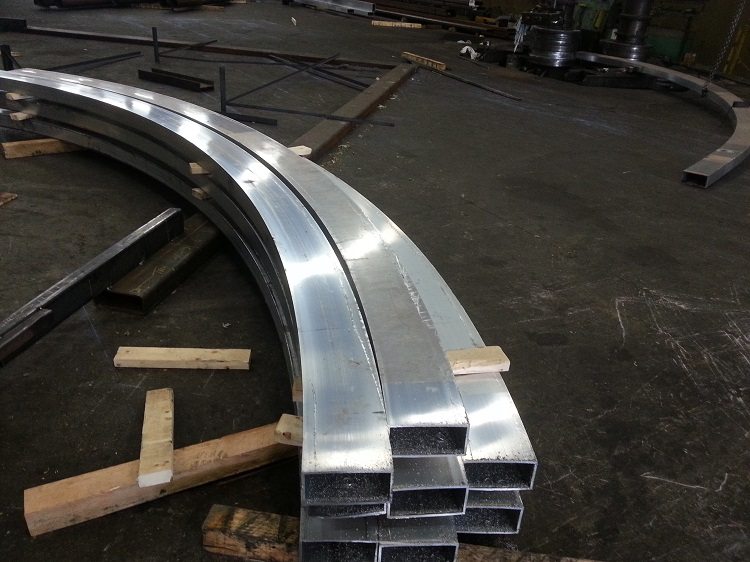

The smoothness and aesthetic appearance of the outer surface of the pipes allow them to be used for decorative purposes without additional processing

A pipe made of aluminum or its alloys has a relatively light weight and resistant indicators to the influence of aggressive chemical and mechanical environments.

Note! The specific weight of the aluminum structure is almost 3 times lower than that of a similar steel.

Such a pipe is not subject to destruction at high humidity, and its inner surface is characterized by low roughness. Aluminum mechanical construction or construction of profile pipes will last a long time. In addition, the aesthetic appearance allows the use of pipes in architectural or design projects.

Assortment of rectangular pipes

The profile pipe made in accordance with GOST has an assortment presented in the table.

Table 3

| Side | The mass of the meter pipe, * 10, g, if the wall, * 10-1 mm | |||||||

| 50-4,0 | 40-2,8 | 30-2,5 | 25-2,0 | 20-1,8 | 15-1,4 | 10-1 | ||

| Difference, not more, * 10-3 mm | ||||||||

| 800 | 560 | 500 | 400 | 360 | 280 | 200 | ||

| Big, * 10-1 mm | Smaller * 10 mm | |||||||

| 140 | 1,0 | — | — | — | — | 19,3 | 15,7 | 11,3 |

| 160 | 1,2 | — | — | — | — | 23,6 | 19,0 | 13,5 |

| 180 | 1,0 | — | — | — | — | 23,6 | 19,0 | 13,5 |

| 180 | 1,4 | — | — | — | 33,0 | 28,0 | 22,2 | 15,6 |

| 200 | 1,2 | — | — | — | 33,0 | 23,0 | 22,2 | — |

| 280 | 2,2 | — | — | 66,4 | 57,6 | 47,6 | 26,9 | — |

| 320 | 1,8 | — | 82,1 | 66,4 | 57,6 | 47,6 | 36,9 | — |

| 360 | 2,0 | — | 95,3 | 76,3 | 65,8 | 54,1 | 41,8 | — |

| 380 | 1,8 | — | 95,3 | 76,3 | 65,8 | 54,1 | 41,8 | — |

| 400 | 2,5 | — | 115,1 | 91,0 | 78,1 | 63,9 | 49,1 | — |

| 450 | 3,0 | — | 137,1 | 107,4 | 91,8 | — | — | — |

| 500 | 3,0 | 175,7 | 148,1 | 115,6 | 98,6 | — | — | — |

| 550 | 4,0 | 216,7 | 181,1 | 140,2 | 119,2 | — | — | — |

| 600 | 4,0 | 230,4 | 192,1 | 148,4 | 126,0 | — | — | — |

Limit deviations for values less than 60 mm are 0.5 millimeters up or down, for 60 mm - ± 0.60 mm. It is also possible to manufacture pipes with dimensions that are not indicated in the table. Moreover, all conditions are agreed with the consumer.

When calculating the mass, the density of the aluminum alloy B95 is adopted, which is 2850 kg / m3. Calculation for other alloys was carried out taking into account conversion factors, which are: for all grades of aluminum - 0.950; for AMts - 0.958; AMCS - 0.958; AD31 - 0.950; AMg0.7 - 0.947; AMg1 - 0.947; AB - 0.947; D1 - 0.982; 1955 - 0.972.

Standardized Product Features

A rectangular shaped aluminum tube may have a length of one to six meters. Other dimensional values must fall within these limits. A pipe of measured or multiple lengths must be produced with maintaining an interval of 0.5 m. The maximum deviation in this case cannot exceed +1.5 cm.

The lateral deflection of the sides of a rectangular pipe should not be more than half a millimeter with a side value of up to 5.0 cm and 0.75 mm for other sides. Regarding the smooth twisting of a rectangular pipe, GOST defines a limit of 1 degree per meter of length.

Note! An aluminum pipe can have a general deviation from straightness, which is not more than the product of its length by the permissible deviation by 1 m of the product.

To eliminate the deviation for the annealed structure with a side of up to 3 cm is allowed by installing it on a flat plate and applying a force of no more than 50 N. The pipe from alloys 1955, D1 with a side above 3 cm can have a straight line deviation of no more than 3 millimeters.

Profile pipe surface requirements

An aluminum rectangular pipe must be cut exactly (GOST 18475) with a cut cut no more than 1/3 of the boundary deviation to its length. This design does not need to deburr. Separation, cracks, spots of corrosive origin, as well as non-metallic inclusions and coarse-crystalline structure are not allowed on the inner or outer side of the product.

An aluminum pipe on its surface can have (if the depth does not affect the wall thickness defined by the standard):

- bubbles

- captives;

- nicks;

- traces of grease (technological);

- Scratches

- traces of broaching and stripping defects.

Indentations in the form of dents, spiral and annular traces of the finish are also possible if the aluminum pipe does not go beyond the limit dimensional frames along the wall thickness. On the surface of products with a wall of up to 2 mm there may be longitudinal risks in an amount of not more than 2 per 1 cm of the perimeter and with a depth of not more than 0.04 mm, and for a wall of more than 2 mm - with a depth of not more than 0.05 mm.

GOST acceptance conditions

Acceptance of rectangular pipes from aluminum and its alloys is carried out in batches that contain structures of one state of material, size, one heat treatment cage and one grade of source material. The quality accompanying document includes information about the manufacturer, consumer, grade of aluminum or its alloy, state of the material, size of products, net mass of the batch, test results, shipping date and standard. In the batch, it is permissible to find heat-treated pipes taken from several cages.

Note! Each aluminum rectangular pipe is subject to verification of its geometric dimensions, the outer surface, the inner surface (with the side of the product above 2 cm).

In order to determine the chemical composition (alloying components and basic impurities) and mechanical properties, 2 pipes are selected from the batch. Other impurities are not determined. The mechanical characteristics of the annealed pipe from A5, A8, AD1, A85, AD0, AD31, AMTSS and AMTS are not controlled by the manufacturer.

If unsatisfactory results are obtained with at least 1 indicator, then the tests are repeated on a doubled sample of pipes. Let's admit piece control of products.

Basic test methods

The aluminum profile pipe is subject to tests to determine the chemical composition, their preparation and selection according to standard 24231. For this, chemical (GOST 25086, 12697.12 and 12687.1) or spectral (GOST 3221) methods can be used. The aluminum alloy pipe is tested according to the standards specified in GOST 18475.

The length of the product is checked by tape measure (GOST 7502) or a ruler of metal (GOST 427). The surface outside is inspected without magnifying devices, and inside - on the illuminated screen. The presence of coarse-grained structures is determined by the roughness of the surfaces of the samples after tensile tests. In the event of a burnout, it is not allowed to re-control the microstructure.

Tensile tests are carried out according to GOST 10006. Change of products on the side at a distance of not less than 7.5 cm from their end and wall thickness is carried out with a micrometer in accordance with document 6507. Temporary corrosion protection, packaging, storage and transportation must comply with standard 9.011.

Product Use Areas

Profile pipes is a material that is used for the installation of a variety of structures, construction of buildings and structures for domestic use, public and industrial needs.

A rectangular pipe is most commonly used:

- in systems of internal heating systems;

- as ventilation ducts and for performing internal wiring of electrical networks;

- in the form of carcasses of structures;

- in mechanical engineering, light chemical, aviation, food, shipbuilding industries;

- in furniture production;

- in lightweight constructions, for example, antennas, advertising media, etc .;

- as decorative elements in design and architecture (more than 70%).

Light weight, good corrosion resistance and strength allow the use of products in various designs to obtain a stable frame. This may be the construction of gates, supporting columns, fences, handrails, protective barriers. An aluminum pipe can act as a power element of the frame of shop windows, shelving and mezzanines.It is indispensable for the production of door or window blocks.

Note! Such products are well combined with other materials that are used in construction.

Due to their good throughput, they are installed in transportation systems of various gases and liquids.

High heat and electrical conductivity, resistance to deformation, lightness, strength and many other characteristics allow the use of rectangular pipes made of aluminum and its alloys in different fields. Designs of such components are characterized by durability and reliability.