An insert into a pipe is the process of connecting secondary branches or channels to a central highway. At the same time, a minimal set of tools and knowledge of many nuances are necessary, since such work is rather complicated. The whole process requires accuracy, and if you have to crash into the main or central channel, it is important to have permits.

Content

Features of the insertion process

PND channels are ubiquitous today. Thanks to modern technologies, tapping into such a pipeline circumvents some of the difficulties inherent in highways with metal pipes.

Firstly, it is not always necessary to stop the flow of gas or water, which will certainly lead to sharp dissatisfaction of the residents who are connected to the system. If the pipeline is connected to an industrial enterprise, then its capacity may decrease. In some institutions (hospitals, maternity hospitals, kindergartens) the lack of water is unacceptable.

Secondly, earlier the insertion process implied the installation of a reducing tee, which has considerable dimensions. Particularly labor-consuming (both in terms of money and time) was the transition from the main section channel to the local pipe.

Thirdly, there is a need to equip a well or chamber for installation and further maintenance of the locking device. Insert under pressure in the HDPE pipe often performed by using a special valve that allows you to completely shut off the flow or adjust it if necessary.

If necessary, you can apply the technology of insertion under pressure, while water does not need to be shut off

Variants of mechanisms for organizing a challenge

For insertion into the pipeline, the production material of which is polyethylene, there are such devices:

- saddle sleeve for cold tapping;

- valve for making tapping under pressure;

- branch pipe overlay (or laid on leaving);

- flange saddle;

- electrically welded saddle sleeve for soldering.

Nurses with a threaded outlet (or clamps for tapping) are designed to organize the removal of a secondary channel from the main pipeline in systems that transport drinking or industrial water. They are widely used in private irrigation and irrigation networks.

The valve for injection under pressure is a special part that can perform such functions:

- a branch with which a pipe branch is mounted;

- shutoff valves capable of blocking or opening the fluid flow through the pipeline.

Installation of overhead care is possible only on the disconnected channel. Unlike the lining pipe, it has a positioning belt to hold the mechanism on the pipe.

Note! The produced diameters of overhead cares vary from 50 to 315 millimeters, nozzles - from 31.5 to 120 centimeters.

The flange saddle is used in the construction and modernization of main sewage and water supply systems for urban or industrial use.The electrowelded saddle is suitable for installation on all types of gas and water PND pipes with a pressure (working) of up to 10 atm for gas and up to 16 atm for water. For gas pipelines, screw and other similar connections are not permissible.

How to crash into pipes without welding using clamps

The tie-in clamp is made of polyethylene or polypropylene in blue or black. Such a saddle is not afraid of corrosion and is durable in use. Reliable and tight connection to the pipe is provided by a rubber sealing ring inserted into a special groove.

The clamp consists of a lower counterpart and an upper threaded part. Its installation on the channel is carried out by tightening the parts using clamping bolts, the number of which depends on the diameter of the element and can be from 2 to 6 pieces. The presence of a threaded outlet allows you to screw in the transition element for the subsequent outlet device.

Before starting installation, it is important to check the presence of all elements of the saddle and its compliance with the diameter of the PND pipe. To do this, halves of the device must be attached to the polyethylene channel. Next, the installation location of the threaded clamp and the hole drilling point are determined. This can be done with a light marker.

After the preparatory steps, an electric or hand drill with a milling cutter having a suitable size, holes are made, the edges of which are cleaned with a sharp knife from burrs and chips. At the final stage, a clamp is installed. Nuts must be tightened evenly crosswise to prevent collapse and overtightening of plastic parts.

Saddle Features

The use of a saddle for HDPE channels is the most optimal option if a tight insert is required, for example, in a buried stationary pipeline.

Polymer saddle - a practical reliable way to cut into a part of the pipeline, access to which is limited

The option of cutting the product and its connection with a tee is wrong, since plastic elements of large diameters can be deformed or it is problematic to enter it due to lack of flexibility. In addition, dirt trapped in the details of the compression sleeve violates the tightness of the connection and fit with the HDPE pipe.

Dimensional characteristics of some saddles for tapping into HDPE pipes are given in table No. 1.

Table 1

| Channel diameter, mm | Branch thread, inches |

| 20 | ½ |

| 25 | ¾ |

| 32 | 1 |

| 32 | ¾ |

| 40 | 1 |

| 40 | ¾ |

| 50 | ¾ |

| 50 | 1 |

| 63 | ¾ |

| 63 | 1 |

| 110 | ½ |

| 110 | 1 |

| 110 | 1 ¼ |

| 110 | 2 |

The material for the manufacture of such fittings is PP-B polypropylene copolymer. The working pressure for elements with diameters of 20-63 mm inclusive is set at 1.6 MPa at an ambient temperature of 20 degrees, with a diameter of 75-110 mm - 1.25 MPa.

Use of overhead care or pad nozzle

Laid on leaving are made of PE100 polyethylene. Its installation is carried out by welding the element in the HDPE pipe using electrodiffusion (electrofusion) welding. A special heating coil located in the lower part of the care, when current is applied to it, melts the polyethylene on the surface of the pipe and the sole of the pipe.

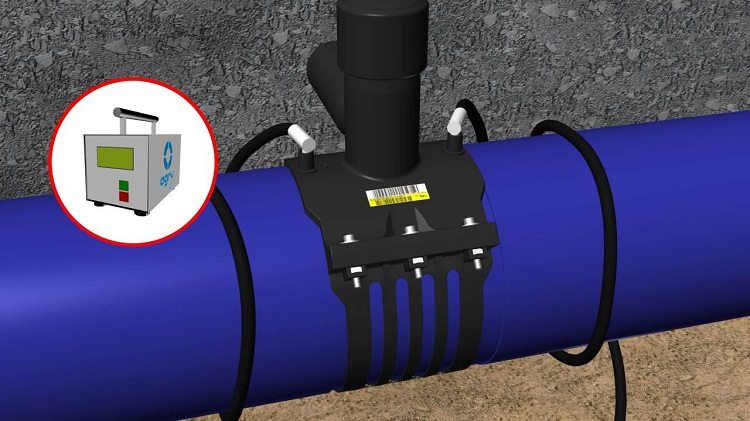

Electro-welded linings provide high tightness of the insert, they can be operated in a limited space

Parameters, welding time and cooling time supplied to the current spiral are adjusted independently by the welding machine. All necessary information is contained in the barcode attached to the nozzle plate by the manufacturer. Guaranteed performance of the received node is at least 25 years.

Laid on care differs from the electrowelded saddle by the absence of a special cutter for cutting into the pipeline and the low cost of laying channels. Although this fitting is installed on a disconnected channel, it has the correct tap angle. Possible production of large diameter pipes.

Due to its size and low weight, overhead care can be installed anywhere in a pipeline under construction or in operation, in cramped city conditions or in a well. Moreover, the process takes a little time and there is no need to cut the HDPE pipe.

Valve Tapping

With the help of a valve, it is possible to insert into non-pressure and pressure-supply water (up to 16 atm) and gas (up to 10 atm) pipelines without disconnecting them. The design features of the cutter allow the process to be carried out with minimal effort. The diameters of the polyethylene channels used for tapping can be 225, 160, 125, 110, 90 and 63 mm.

The insert is made by milling the pipe wall with an annular mill with a lower and upper stop, which moves along a metal sleeve and is controlled by a steel drive spindle. The metal elements of the mechanism do not require maintenance and additional insulation. The shut-off valve is controlled by a boom.

Note! The diameter of the cutter must be less than the internal section of the tap. This eliminates the formation of leaks at the junction.

An electrofusion welding machine is used to mount the valve for pressure tapping. At the bottom of the part there is an open heating element that provides optimal heat transfer. A channel with a diameter of 63, 50, 40 or 32 mm can be connected to the branch pipe.

Using flanged and electrowelded saddles

The flanged saddle is used for inserting into the PND pipeline with a pressure (working) of up to 16 atm in diameter from 8.0 to 60.0 cm; output flange - from 4.0 to 15.0 cm. Shutoff valves, flanged taps, gate valves or a secondary channel with a welded flange can be attached to it immediately. The body of the element is made of malleable cast iron, on which an epoxy powder coating is applied to protect metal parts from corrosion and to provide high resistance to aggressive media.

The flange saddle is fixed by two clamps, covered from above with a movable rubber casing, which simplifies the installation of the saddle on the pipe. Sealing of the connection is provided by the rubber sealing part.

To install an electrowelded saddle, you must:

- attach the upper part of the branch to the pipe, draw a line with a marker along the contour of the part;

- use a hand scraper to remove the oxide layer from the polyethylene channel (approximately 0.155 mm deep);

- degrease welded surfaces, ensure their cleanliness and dryness;

- install the saddle parts on the pipe and secure;

- conduct welding operations with an electrofusion device;

- cut a hole in the pipe with a cutter, which allows you to perform work on pipelines under pressure.

The last step involves removing the plug on the bend, turning the cutter to the lower stop, turning the cutter to the upper stop and putting the plug on.

Inserting into a pipe without welding is indispensable when connecting household appliances to a water supply network or creating an additional sewer drain. This operation is especially relevant when working with plastic pipes.