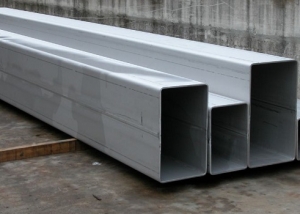

Profile pipes are widely used in private and industrial construction. From them create arbors, greenhouses, garages, outbuildings, billboards. Designs are not only classic rectangular, but can also have the most diverse configuration. Therefore, it is very important to correctly calculate the maximum allowable pipe bend. This will provide the building with strength, durability and will allow to maintain its original shape.

In the manufacture of structures from a profile pipe, it must not be bent “by eye” - appropriate calculations should be made

Content

Properties and features of shaped tubular products

It is customary to name pipes as pipes, the cross section of which differs from round. The most common options are square and rectangular products. They are especially popular with the fact that the final design created on their basis has a relatively low weight. Moreover! Due to its specific shape, the fastening of the tube elements to various surfaces and to each other is greatly simplified.

These building products are made from a wide range of alloys and metals. However, profile pipes made of low alloy and carbon steel are most often used. Each metal is characterized by such a natural quality as a resistance point. It can be both maximum and minimum. The first, in particular, causes the deformation of the constructed structures, leads to excesses, which can result in kinks.

When bending, it is important to take into account such characteristics as the type of product and its density, cross-section, size, as well as the flexibility of the material and its rigidity. Knowing all these properties of the metal, the contractor will be able to understand how the structure will behave during operation.

In addition, it should be remembered that when the product is bent, its internal parts are compressed, which leads to an increase in their density and a decrease in size. The length of the outer layer increases accordingly, it becomes more stretched, but less dense. Moreover, even at the end of the process, the initial characteristics of the middle sections are preserved.

When bending a pipe, it is necessary to take into account the properties of the material from which it is made, its dimensions and wall thickness

Important! Stress during bending of the pipe profile will necessarily occur even at the product segments as far as possible from the neutral zone. Especially high pressure will experience layers located in the immediate vicinity of the above neutral zone.

How does material strength affect allowable bending radii?

GOSTs operating in the territory of our country regulate in sufficient detail the characteristics and properties of the elements used in calculating the bending strength of the pipe. First of all, in this context, we consider the minimum radius by which it is allowed to bend a shaped tubular product. It depends on the bending conditions. If this procedure is carried out with heating or with packing of the pipe cavity with sand, the value of the outer diameter starts at 3.5 DN (DN refers to a conditional pass).

In the case when the contractor can use specialized equipment (for example, a pipe bending machine) that allows you to perform the sequence of necessary operations without heating, or other additional measures, then the minimum diameter is 4 DN.

If it is necessary to perform a sufficiently sharp bend, the diameter should be at least 10 DN, since this procedure will be carried out by other methods, mainly at high temperatures.

Of course, the values provided by state standards can be slightly reduced, but then it is necessary to calculate the profile pipe for bending very carefully. Deviations from GOST are possible if, with the used method of bending, the wall thickness is guaranteed to change from the original by 15%. Only then can you be sure that bending by smaller values will not have a significant effect on the strength of the structure in the future.

You can bend the pipe to the maximum radius allowed for it only with the help of a special machine or device

What formulas and tables are used

For the correct calculation of the pipe bending strength, it is necessary to find out the length of the part. This is done according to the following formula:

D = 0.0175 × P × Y + p1, where

D is the length of the workpiece; P is the bending radius of the pipe (mm); Y is the required bending angle; p1 is the distance to hold the workpiece required when using special equipment.

Next, we evaluate the magnitude of the proposed bending section according to this formula:

D1 = π × Y / 180 (P + DN / 2), where

D1 - the length of the bent section; π is a known mathematical constant; Y - bending angle (degrees); DN - diameter on the outer surface of the pipe (mm).

GOSTs No. 617/90 and No. 494/90 contain the smallest values of the main characteristics, on the basis of which the strength of the profile pipe product in bending is calculated.

Good to know! This approach - the regulation of minimum values - provides the convenience of the master, as well as the greatest safety when performing work and, of course, during the operation of structures, in particular, constructed from brass and copper profiles.

The main characteristics used in the process of calculating the bending strength of a pipe are given in the table below.

Table 1

| Minimum bending radius | Minimum free length | External diameter |

| 90 | 60 | 30 |

| 72 | 55 | 24 |

| 36 | 50 | 18 |

| 30 | 45 | 15 |

| 24 | 35 | 12 |

| 20 | 30 | 10 |

| 16 | 25 | 8 |

| 12 | 18 | 6 |

| 8 | 12 | 4 |

| 6 | 10 | 3 |

The data in this table are for tubular brass and copper products. And the calculation of the bending load on the profile pipe made of steel is carried out in accordance with the data below (GOST No. 3263/75).

table 2

| Pipe size | Free length (minimum) | Minimum bending radius | ||||

| Conditional pass | External diameter | Hot condition | Cold condition | |||

| 100 | 114 | 230 | 340 | 680 | ||

| 80 | 88,5 | 170 | 265 | 530 | ||

| 65 | 75,5 | 150 | 225 | 450 | ||

| 50 | 60 | 120 | 180 | 360 | ||

| 40 | 48 | 100 | 150 | 290 | ||

| 32 | 42,3 | 85 | 130 | 250 | ||

| 25 | 33,5 | 70 | 100 | 200 | ||

| 20 | 26,8 | 55 | 80 | 160 | ||

| 15 | 21,3 | 50 | 65 | 130 | ||

| 10 | 17 | 45 | 50 | 100 | ||

| 8 | 13,5 | 40 | 40 | 80 | ||

The main parameters that must be taken into account when determining the bending load include wall thickness and the diameter of the workpiece. The correlation of these two indicators is presented in the next table. By the way, the information contained in it can be used to calculate the load on the pipe of circular cross section.

Table 3

| Diameter (mm) | Bending radius (minimum) for wall thickness | |

| Thickness is more than 2 mm | Thickness less than 2 mm | |

| 60/140 | 5D | 7D |

| 35/60 | 4D | 6D |

| 20/35 | 3D | 5D |

| 5/20 | 3D | 4D |

There is one more thing to be said. Various on-line calculators present on the Internet are called upon to replace the manual calculation of the load of the type in question. They work in accordance with the formulas laid down in them, oriented to various samples of pipe products. The range of applications of a modern online calculator is very wide: starting from the simplest calculation of a round pipe for deflection, and ending with the calculation of the load on the profile pipe when it is bent.

Deformation of the pipes at the bend is sometimes inevitable, but it can degrade the performance of the finished structure

Bending process

Any deformation leads to a decrease in the bearing capacity of the profile pipe and is accompanied by the appearance of prolonged stresses on its walls. On the inner layer, due to compression of the metal, the density increases, and on the outer part, tension, on the contrary, decreases the value of this indicator. The cross-sectional shape also changes as expected. The combination of these factors leads to the fact that the bearing capacity of the structure at the bend is significantly reduced. This is true for a round pipe, as well as for a rectangular and square pipe product. Moreover, for the last two, this phenomenon is not so pronounced than for a pipe with a circular cross section.

However, in any case, a careful approach to assessing the degree of applied load during bending of the workpiece is required. Then unnecessary faults and curvatures will not appear on it. From the point of view of the functional purpose, this concerns, first of all, round pipes from which bends for water supply systems are made.

Good to know! The formed folds lead to blockages, increase the resistance of the transported fluid and reduce the permeability of the working medium.

Therefore, the degree of oval deformation for a part with a diameter of up to 20 mm should not exceed 15 percent. With an increase in diameter, the value of this indicator decreases to the level of 12.5 percent. The same numbers are also used to determine the optimal load on the deflection of a pipe with a profile cross section, and the above diameters refer to the rectangle (a) or square (a) of the circle inscribed / described in / around.

Apply Hooke's Law

The calculation of the bending strength of a tubular product is reduced, according to Hooke's law, to a simple determination of the maximum stress value for the structural point under study. In this case, it is important to consider what material the profile is made of, since each of them is characterized by its own stress indicator.

According to Hooke's law, the elastic force is in direct proportion to the degree of deformation. In general, the following formula is used for calculations:

H = P / V, where

N is the voltage; P is the magnitude of the bend along the axis of the applied force; V is the value of the bending resistance, which is taken along the above axis.

When bending pipes, it should be remembered that the load on the workpiece should not be too strong, otherwise the pipe will simply burst

Determining the normal value of resistance is included in the circle of the main tasks of a person who has decided to erect a structure from a profile. And the use of the formula for calculating the optimal level of force acting on the pipe involves the verification of the correctness of the results. To do this, you need to know a number of rules and, of course, follow them. They are briefly formulated as follows:

- Before proceeding with the calculations, it is necessary to draw at least a sketch of the future design. So you will be insured against errors caused by a misunderstanding of the shape of the structure;

- in order to prevent deformation or destruction of the profile that impede the operation of the building, the material of its manufacture and wall thickness should be taken into account;

- Having calculated the bending strength of the pipe, it is necessary to carefully study the results. They must not exceed the maximum values.

Well, the basic rule is: do the calculations slowly, accurately, accurately. Use appropriate formulas at each stage, do not adjust the values to ones that are beneficial for yourself.