The PPU shell is a semi-rigid (rigid) cylindrical product made of low-density polyurethane foam, which ensures insulation, and, more precisely, thermal insulation of various pipelines. Such a heater is considered the most effective for pipes with a coolant or products of the petrochemical industry. The technical parameters of the state of the channels with PPU insulation are continuously monitored by the UEC system (operational remote control).

The so-called "shell" of polyurethane foam is used for thermal insulation of pipelines for various purposes

Content

Design features of the insulating PUF shell

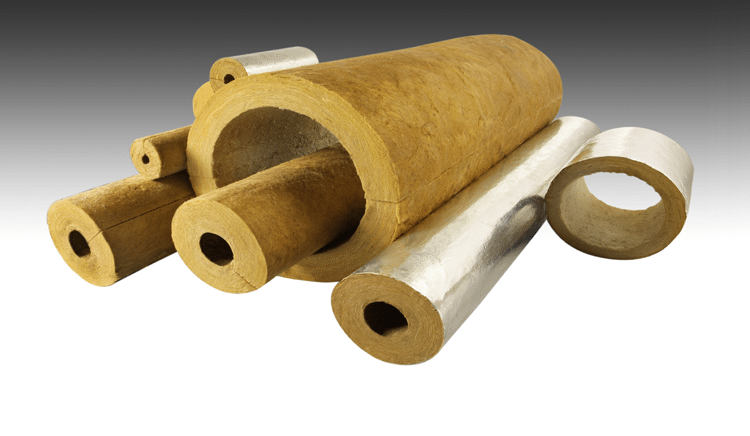

Structurally, the shells made of polyurethane foam are half-cylinders one meter long, the inner diameter of which corresponds to a similar parameter of insulated pipelines.

Note! To facilitate installation work, the products are equipped with locking longitudinal and transverse elements that provide the most tight connection.

PPU density is approximately 60 kg / m3, which greatly simplifies the assembly and transportation of shells for pipe insulation. Such thermal insulation is fixed using glue or foam, as well as iron screeds. Corner elements are used to warm the trunk with a bend.

Molds are used for the production of heat-insulating polyurethane foam PPU shells for pipes. Depending on the operating conditions, such products can be manufactured with an auxiliary coating of galvanized steel, aluminum foil, mastic, reinforced foil or fiberglass. Such protective layers increase the characteristics of deformation and mechanical strength, as well as increase the service life of the shell-insulation.

Main product sizes

The characteristics and dimensions of heat-insulating PUF shells for pipes are presented in the technical specifications (5758-019-01297858-01) for the products. According to the document, the inner diameter of the products may be: 142.0; 122.0; 102.0; 92.0; 82.0; 72.0; 63.0; 53.0; 42.6; 32.5; 27.3; 21.9; 15.9; 13.3; 10.8; 8.9; 7.6 and 5.7 centimeters. The length of the heat-insulating PPU of the shell varies from 100 to 200 cm, but, having agreed with the customer, it is possible to change it.

The thickness of the product should be equal to the same parameter of the insulated layer of pipes and is selected from the table.

Table 1

| External section of steel pipes, cm | The thickness of the shell-insulation for pipes, mm |

| 5,7 | 38,5 |

| 7,6 | 39,0 |

| 8,9 | 42,5 |

| 10,8 | 43,0 |

| 13,3 | 54,5 |

| 15,9 | 38,6 |

| 21,9 | 43,1 |

| 24,5 | 49,4 |

| 27,3 | 57,2 |

| 32,5 | 55,5 |

| 42,6 | 58,2 |

| 53,0 | 40,2 |

| 53,0 | 78,9 |

| 63,0 | 72,5 |

| 82,0 | 72,4 |

| 92,0 | 74,4 |

| 102,0 | 70,4 |

| 122,0 | 60-100 |

| 142,0 | 60-100 |

At the request of customers and design justification, the thickness of the PPU insulation shells can be changed.

The radial angle of products with a diameter of 5.7-53.0 cm inclusive is 180 degrees; 63.0-82.0 cm inclusive - 120 degrees; for pipes with a cross section of more than 82.0 cm - 90 degrees. The geometric characteristics of the PUF shells insulating pipelines may have deviations shown in the table.

table 2

| Name of geometric characteristic | Name of parameter deviation | The value of the limit deviations |

| Outside diameter | Deviation in the outer cross-section of the shell, mm | +5 |

| Length | Deviation in length, mm | ±10 |

Technical characteristics of PPU

Shells for pipes are made from rigid freon-free filling polyurethane foams. Their physico-chemical properties must be consistent with GOST 30732 from 2001 and the table.

Table 3

| Name of indicator | unit of measurement | Value |

| Appearance | — | A fine-meshed yellow to dark brown color structure |

| Density, not less | kg / m3 | 60,0 |

| Stress at 10% deformation under compression, not less | kPa | 300 |

| Water absorption, not more | % by volume | 10,0 |

| Thermal conductivity at 20 degrees, no more | W / m * K | 0,035 |

| Thermal conductivity at 50 degrees, no more | W / m * K | 0,033 |

| Volume fraction of pores (closed), not less | % | 88 |

| Use temperature, not more | ºС | 150 |

| Shear strength (axial direction), not less | MPa | 0.12 (at a temperature of 23 ± 2 ºС)

0.08 (at a temperature of 140 ± 2 ºС) |

| Shear strength (tangential direction), not less | MPa | 0.2 (at a temperature of 23 ± 2 ºС)

0.13 (at a temperature of 140 ± 2 ºС) |

| Thermal insulating radial creep at test temperature 140 ºС, not more | mm | 2.5 (within 100 hours)

4.6 (within 1000 hours) |

In many respects, polyurethane foam is more profitable than other materials for insulation. Its disadvantage is destruction under the influence of ultraviolet radiation. The approximate rate of destruction is 0.05 mm per year. Under the action of the sun, the structure will begin to exfoliate, peel off and lose stiffness.

To prevent the destruction of PUFs by ultraviolet radiation, the insulating layer is coated with a polymer

The main advantages of polyurethane foam insulation

Polyurethane shells have a number of significant advantages, largely due to which they are superior to other insulation materials for pipes. Among them are:

- efficiency;

- resistance to decay, pests, as well as chemicals;

- the possibility of using in a wide temperature range;

- fire safety;

- repeated use;

- environmental friendliness;

- minimization of expenses for repair of pipelines;

- ease and speed of installation.

If it is necessary to repair a certain section of PPU pipes, the insulation is neatly and easily removed, and upon completion of work it is installed in its place. Due to this, the speed and efficiency of the repair process is significantly increased. With PPU there are no difficulties in storage, transportation and loading / unloading.

Note! Under normal conditions, the coefficient of moisture absorption of the material is 0.5. PPU is only able to absorb moisture under pressure.

Light weight, easy-to-understand wiring diagram and available fastening methods provide high installation speed. A thermal insulation system for 1 shift can be installed by two workers on a pipeline with a length of up to 300 linear meters.

For the installation of the shell does not require large expenditures, a small team of workers can easily cope with the work

Options for using polyurethane foam insulation

PPU shells for pipes with a diameter of 108 and 133 mm are used for thermal insulation of sewer pipes. Products with a section of 1.5; 2.0; 3.2; 4.5 and 5.7 cm usually serve as insulation elements of internal heating and water supply channels. PPU shell for pipes elevator nodes and heat points usually has a diameter of 8.9; 10.8; 13.3; 15.9 and 21.9 cm. Products for 27.3 are used for trunk and technological pipelines; 32.6 and 102.0 cm.

Foiled shells for pipe insulation are installed indoors. Such a system is not suitable for use in heating mains with channel or channelless laying. PPU shell coated with reinforced foil can be mounted both inside and outside buildings. Such a foil reliably protects the insulating layer from the action of precipitation.

Note! If the heat-insulating shell is covered with fiberglass or moisture-resistant plastic, then the system is applicable for all types of pipelines, especially for those laid directly in the ground.

Galvanized insulation for pipes (PPU shells) are used mainly for open type laying on highways of regional and city scales, as well as oil and gas pipelines.

Technical parameters of other materials for insulation

In addition to PPU with UEC, pipes can be insulated with other materials. The table shows some technical parameters of such insulators in comparison with polyurethane foam.

Table 4

| Parameter | Coefficient of thermal conductivity | Operation duration | Working temperatures | Porosity structure | Density |

| unit of measurement | W / m * K | Years old | Degrees | — | kg / m3 |

| Hard PPU | 0,025 | 30-50 | from -200 to +180 | Closed | 40-200 |

| Traffic jam. plate | 0,050-0,060 | 3 | from -30 to +90 | Closed | 220-240 |

| Mineral wool | 0,052-0,058 | 5 | from -40 to +120 | Open | 55-150 |

| Styrofoam | 0,040-0,050 | 5-7 | from -50 to +110 | Closed | 30-60 |

| Foam concrete | 0,145-0,160 | 10 | from -30 to +120 | Open | 250-400 |

Another fairly common material for insulation is expanded polystyrene (PPS). With the same shape and size, the insulation system from PPU will have a higher density than from PPP. In other words, polyurethane foam is stronger than expanded polystyrene.

PPP is characterized by such values of the main indicators:

- density: 25-50 kg / m3;

- thermal conductivity at 25 degrees: not more than 0.038-0.042 W / m * K;

- water absorption: not more than 1.0%;

- operating temperatures: -50- + 75 ºС.

Expanded polystyrene can be used for all pipelines, except for those that carry steam or superheated water.

The need for a UEC system for PPU pipes

The channel insulation is equipped with a UEC system, the main task of which is to control the moisture state of polyurethane foam during pipeline operation. In the absence of such monitoring, timely detection of pipe section corrosion is practically impossible. The system helps prevent accidents and minimize repair costs.

Note! The moisture content of the insulating layer may increase due to the penetration of soil moisture into it or due to leakage of the coolant due to joint defects or corrosion.

The UEC system consists of the following elements:

- copper signal conductors in the pipeline insulation layer, which run along its entire length (main and transit indicator wire);

- terminals for switching signal conductors-indicators at control points and connecting devices;

- cables

- damage detector (portable or stationary).

Linear indicator conductors for UEC must be placed at a distance of 10 to 25 millimeters from the surface of the pipe. They are made of wire with a cross section of 1.5 mm2. The permissible resistance of the conductors of the ODK system is 0.012-0.015 Ohm per meter per meter. To connect and connect control devices, an end, intermediate, double end, uniting or through terminal are used.

For the UEC system, it is necessary to provide the following threshold values of the parameters: electrical resistance of the loop (signal circuit) - approximately 200 Ohms (for a pipeline of 5 km); insulation resistance (electrical) of 1-5 kOhm.

Compared to other materials for insulation, polyurethane shells for pipes are more effective, but at the same time they are inexpensive. If thermal insulation from basalt needs to be replaced about once every 3-4 years, then PUF with UEC can solve a similar problem for at least 30 years. Due to the low installation costs and insignificant heat losses, such insulation quickly pays for itself.