Gate valves are widely used in pipelines of both industrial and domestic use. Similar details in production are more common due to their impressive weight and dimensions. The purpose of the flange gate valve with a rubber wedge is to shut off the flow of the working medium transported through the pipeline. The locking or regulating element of such valves moves perpendicular to the direction of movement of the pumped products.

Varieties and Design

In general, a valve may be:

- gateway;

- parallel. Modern industry produces a parallel flanged valve with a sliding spindle and with a rotatable (non-sliding) valve.

- hose.

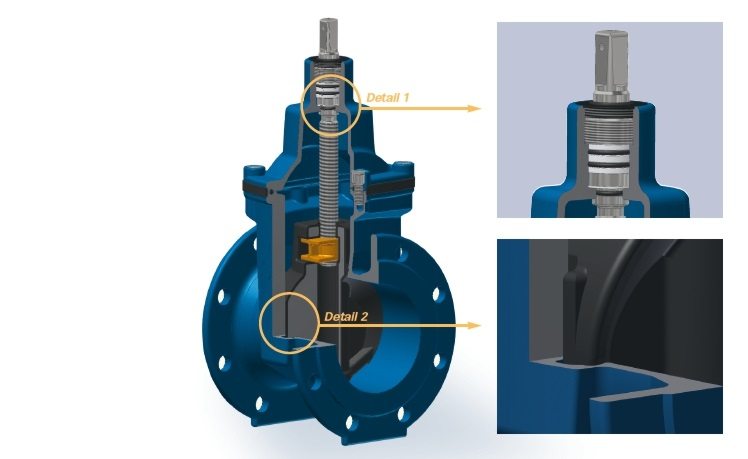

In accordance with the name, the wedge gate valve has a wedge shape. In this case, the sealing surfaces - saddles - are located relative to each other at a certain angle. The surface of the wedge under the action of the pressing force transmitted by the spindle due to elastic deformation changes shape, which ensures a snug fit to the saddles. The scope of the slide gate valve is the place where you want to create a high degree of shutter tightness when it is closed.

By design, the design itself is:

- double disc. She found her embodiment in a parallel valve.

- elastic;

- tough.

The shutter is adjusted using a spindle or damper. The product is connected to the pipeline from two sides through the flanged, socket or welded-on connecting ends on its body. One of the drawbacks of the design with a sliding locking element is that for its exit it is necessary to leave a place no less than the diameter.

A threaded pair with a spindle is formed by a running nut. The rotation of one of the elements of this pair provides the shutter to move in the necessary direction.

In a two-disc product, two disks form a wedge, which are self-mounted relative to the seats. Seals are characterized by high wear resistance, which is why the double-disc flange gate valve has a very long service life. The advantage of this type of design is the absence of jamming. An important factor is also that closing a double-disc flange gate valve requires less effort.

The elastic wedge also has two disks connected by an elastic part. Such a technical solution provides complete blocking of the channel, even if there are errors in the dimensions of the wedge itself.

A rigid wedge closes the gap between the saddles, as they say, tightly.

Important! However, since adjusting the angle of a given element can be very difficult, it can simply jam.

Rubber wedge gate valve operating parameters

Typical experts include the following technical characteristics of these products:

- high tightness. GOST 9544-93 classifies valves having a rubberized locking element to class “A”. That is, in such a node, leaks are guaranteed to be absent;

- long service life.Overhaul of the control unit will be required no earlier than 16 years after commissioning, and the case, with proper handling, will “live” even longer;

- universality. Gate valves with rubberized wedge are ready to work in systems for transporting liquid and gaseous media;

- limited size of the throughput (conditional) diameter. The value of this parameter is within 15 ... 300 millimeters;

- wide temperature range. Gate valves, the design of which includes a rubberized shut-off element, are able to work with media with temperature.

And these indicators are not limiting. So, for example, the model 30h6nzh of a flange parallel two-disk valve with a sliding spindle withstands the flow temperature up to -15 ° C. But there is one limitation: similar products are applicable in pipelines with fluids that neutralize their parts.

Alternatives

The relevance of the use of this type of product led to the appearance on the market of other products that successfully perform the functions of a slide gate valve with a rubber wedge. This is, first of all, the material of manufacture. Most of these parts have two significant drawbacks:

- the above temperature range may not be sufficient to work in specific conditions;

- at very high pressure in the pipeline, a slide gate valve with a sliding spindle can simply fail. For example, a cast-iron part withstands only 10 atmospheres.

Against this background, the use of a slide gate valve-stainless steel flange looks preferable. Its advantages include:

- the possibility of operation on pipelines transporting various media: water, air, natural gas, petroleum products and steam;

- reliable blocking of the flow and a high degree of sealing;

- excellent maintainability;

- simplicity of construction;

- large assortment: there are stainless gate valves with a sliding spindle on the market, the passage diameter of which can reach 3 meters. Moreover, unlike the cast iron ones, they are not afraid of pressure even in a thousand atmospheres!

The main advantage of the gate valve is the simplicity of the design, which greatly simplifies the repair in case of failure

Helpful information! One of the most popular stainless steel gate valves today is the 30s41nzh model. Its design includes a retractable locking mechanism that can withstand pressures up to 16 atmospheres and a range of operating temperatures ˚C.

We should also mention the disadvantages of these elements of the pipeline.

- short juice of seal service during intensive operation;

- low efficiency of flow control. The overlap process takes a certain period of time;

- due to its impressive dimensions, installation of steel valves with a sliding spindle is possible only in certain conditions.

There is another type of shutoff valves, which today is widely used in pipelines. This is a flange hose valve. Its body does not have a seat, and the shutter is formed by several sealing surfaces. The movement of the working medium in the hose valve is carried out through a flexible pipe, which is clamped if necessary with a special spindle. Despite its simplicity, it is impossible to call this design a full-fledged stop valve.

The advantages of a hose valve include:

- transportation of the medium is unhindered, since clogging of the nozzle is impossible;

- the hose valve has a low hydraulic counteraction;

- contact with the working medium is carried out only by means of a nozzle;

- complete sealing of the structure.

- The cross-section of the hose valve is full bore.

When using this device, you must monitor the condition of the flexible pipe. Due to constant loads, it wears out quickly.To replace it, you must be guided by the attached instructions. This can be done very quickly, without using a special tool.