Regulatory document GOST 3262 published in 1975. It extends to galvanized as well as non-galvanized steel welded communications with / without cut or rolled cylindrical threads. Such pipes are applicable for gas pipelines, water pipelines, heating systems, as well as parts of water-gas pipeline (GWP) structures. The document reflects the assortment, test methods, technical requirements and acceptance rules.

Steel pipes manufactured in accordance with GOST 3262-75 are used for the installation of domestic and industrial water and gas pipelines

Content

Features of steel communications

The main material for making VGP pipes is carbon steel. Production technology includes the preparation of metal billets, their molding, as well as the implementation of the seam by electric welding.

For installation, two methods are often used:

- using electric welded joints;

- using couplings and other equipment.

The positive qualities of VGP communications include strength (exceeding the performance of plastic and copper products), low linear expansion, good thermal conductivity, resistance to high pressure values, oxygen and gas tightness.

Note! If it is necessary to lay an open route, a pipeline transporting gas or install a heating system with an operating temperature above 100 degrees, then the use of other communications, except for VGP, is impossible.

The service life of the products depends on the substance transported.

Product range in accordance with GOST

Standard 3262-75 defines the dimensions and weight of a steel pipe.

Table 1

| Conditional pass | Wall thickness 10-1 mm / mass 1 meter of product in kg | Outside diameter | ||

| light pipe | ordinary pipe | reinforced pipe | ||

| 6 | 18/0,37 | 20/0,40 | 25/0,47 | 10,2 |

| 8 | 20/0,57 | 22/0,61 | 28/0,74 | 13,5 |

| 10 | 20/0,74 | 22/0,80 | 28/0,98 | 17,0 |

| 15 | 235/1,10 | -/- | -/- | 21,3 |

| 15 | 25/1,16 | 28/1,28 | 32/1,43 | 21,3 |

| 20 | 23,5/1,42 | -/- | -/- | 26,8 |

| 20 | 25/1,5 | 28/1,66 | 32/1,86 | 26,8 |

| 25 | 28/2,12 | 32/2,39 | 40/2,91 | 33,5 |

| 32 | 28/2,73 | 32/3,09 | 40/3,78 | 42,3 |

| 40 | 30/3,33 | 35/3,84 | 40/4,34 | 48,0 |

| 50 | 30/4,22 | 35/4,88 | 45/6,16 | 60,0 |

| 65 | 32/5,71 | 40/7,05 | 45/7,88 | 75,5 |

| 80 | 35/7,34 | 40/8,34 | 45/9,32 | 88,5 |

| 90 | 35/8,44 | 40/9,60 | 45/10,74 | 101,3 |

| 100 | 40/10,85 | 45/12,15 | 50/13,44 | 114,0 |

| 125 | 40/13,42 | 45/15,04 | 55/18,24 | 140,0 |

| 150 | 40/15,88 | 45/17,81 | 55/21,63 | 165,0 |

Pipes of a light series, which are designed for thread rolling, according to GOST can be manufactured with such values of mass and size.

table 2

| Outside diameter | Mass of one meter, kg / wall thickness | Conditional pass |

| 16 | 0,69/2,0 | 10 |

| 20 | 1,08/2,5 | 15 |

| 26 | 1,45/2,5 | 20 |

| 32 | 2,02/2,8 | 25 |

| 41 | 2,64/2,8 | 32 |

| 47 | 3,26/3,0 | 40 |

| 69 | 4,14/3,0 | 50 |

| 74 | 5,59/3,2 | 65 |

If the thread is made by knurling, then document 3262 on steel communications allows a reduction in internal diameter along the length of the thread to 10%. To calculate the mass of the pipe, the GOST takes the density of steel 7.85 g / cm3. Galvanized pipe is 35% heavier than un galvanized.

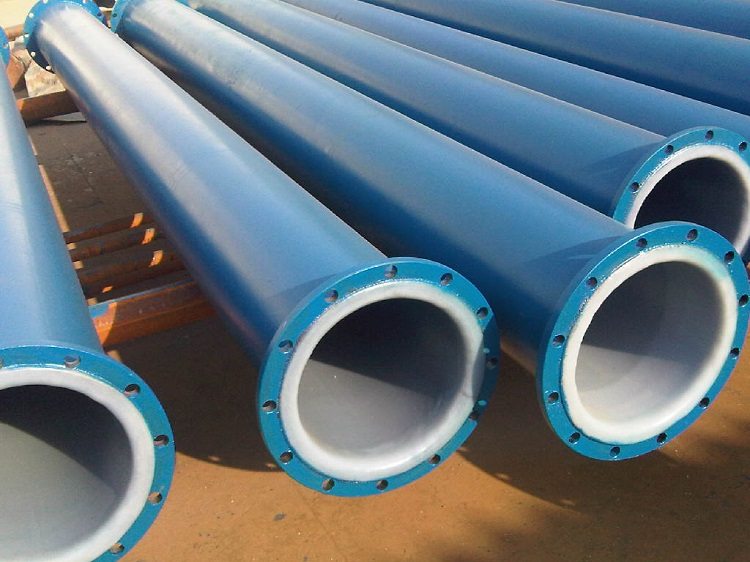

Zinc coated pipes are more durable and last longer than usual, since zinc protects the metal from corrosion

Limit deviations in steel pipe parameters

GOST 3262-75 gives the maximum deviations that are allowed for the dimensions of VGP pipes:

- with normal manufacturing accuracy for an outer diameter with a nominal bore of up to 4 cm inclusive, the deviations are from -5 * 10-1 up to + 4 * 10-1 mm (with increased accuracy from -4 * 10-1 up to + 4 * 10-1 mm)

- above 4 cm - from -1.0% to + 0.8% (with increased accuracy from -0.8% to + 0.8%);

- wall thickness -15% (with increased accuracy -10%).

The maximum deviation of the pipe wall thicknesses according to 3262-75 is limited by the deviations of its mass.

Note! Products of ordinary manufacturing precision are used for heating systems, gas pipelines, water pipelines, and high accuracy - for parts of gas and water structures.

By weight, the steel pipe is limited to + 8%. According to customer requirements, this parameter should not exceed + 7.5% for a batch and + 10% for a single product. For one meter of its length, the curvature of the communications according to 3262-75 cannot exceed:

- 0.15 cm if the conditional pass is higher than 2 cm;

- 0.2 cm, if the conditional pass is up to 2 cm inclusive.

For each type of pipe there are maximum permissible deviations from the parameters that are regulated by GOST

GOST provides requirements for threading on VGP products.

Table 3

| Conditional pass | Thread Length | With conditional number of threads | |

| short | long | ||

| 15 | 9,0 | 14 | 14 |

| 20 | 10,5 | 16 | |

| 25 | 11,0 | 18 | 11 |

| 32 | 13,0 | 20 | |

| 40 | 15,0 | 22 | |

| 50 | 17,0 | 24 | |

| 65 | 19,5 | 27 | |

| 80 | 22,0 | 30 | |

| 90 | 26,0 | 33 | |

| 100 | 30,0 | 36 | |

| 125 | 33,0 | 38 | |

| 150 | 36,0 | 42 | |

For conditional passages 10, 8 and 6, the length of the thread and the number of threads are not defined.

Requirements for steel VGP pipes

GOST 3262-75 determines that the manufacture of pipes should be made of steel according to GOST 380, as well as GOST 1050, published in 1988. In this case, the mechanical properties and chemical composition are not standardized. Document 3262 establishes that parts for VGP structures are made of steel according to GOST 1050.

At the ends of the communications to be welded, having a wall of 5 mm or more, bevels comprising angles of 35-40 ° to their end should be removed. In this case, it is necessary to leave the end ring with a width of 10 to 30 (* 10-1) millimeters.

Document 3262-75 permits, at the request of the consumer, threading on reinforced and ordinary products with a conditional pass of more than 1 cm at both ends. Pipes can also be equipped with couplings that are manufactured according to the standards 8966-75, 8944-75, 8965-75 and 8954-75.

According to normative document 3262, captures, cracks, sunsets and swellings are unacceptable on the surface of VGP communications. The ends of the pipe should not be delaminated.

It is permissible to have a layer of scale that does not impede inspection, as well as individual marks, dents, rowaness, traces of stripping and other defects that are caused by the production method, provided that they do not divert the wall thickness to the minimum required values.

The appearance of steel pipes is also important for quality control - the presence of extraneous inclusions or a heterogeneous surface structure is not allowed

Technical parameters of VGP pipes according to GOST 3262

Trimming the ends of the VGP pipes must be performed at a right angle. The permissible bevel is not more than 2 °, and the remaining burrs are not more than 0.5 mm.

Note! A galvanized pipe must have a continuous zinc coating over its entire surface, the thickness of which is not less than 30 microns. In this case, the ends and threads may not have such a layer.

The surface of the galvanized steel pipe (GOST 3262-75) does not allow the presence of bubbling, foreign inclusions and peeling of the coating. Individual non-galvanized sections on 0.5% of the outer side of the pipe can be corrected in accordance with GOST 9.307.

The withstand hydraulic pressure for VGP pipes (according to standard 3262-75) is:

- 3100 kPa for reinforced pipes;

- 2400 kPa for ordinary and light pipes.

At the request of the consumer, this value may be 4900 kPa. For pipes with a nominal bore of up to 4 cm inclusive, bend tests are carried out using a mandrel whose radius is 2.5 of the outer diameter of the product. For VGP communications with a conditional pass of 5 cm - a radius of 3.5 outer diameters.

At the request of the consumer, distribution tests can be carried out. So, for products with a conditional pass of 1.5-5.0 cm, the required value is not less than 7%, for products of 65 mm and more - not less than 4%. In addition, they must withstand flattening tests to a distance equal to 2/3 of the outer diameter of the pipe.

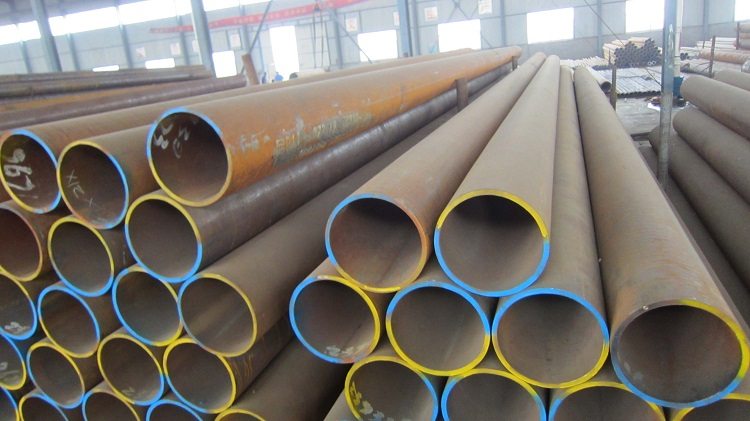

Steel pipes are the basis of many high pressure pipelines, so the produced samples pass rigorous strength tests

Acceptance rules in accordance with GOST 3262-75

Steel pipes are accepted in batches. Each of them includes products of the same brand and one size. The batch mass is not more than 60 tons. Each pipe passes a check of dimensions, surface and curvature. The control of the outer diameter is carried out at a distance of more than 1.5 cm from the end of the product.

To check the parameters of the thread, tests for bending, flattening, distribution, burrs, the height of the burr inside, the bevel angle and right angle, as well as the mechanical properties, 1% of the pipes are selected, but not less than 2 from the batch.

Each product is tested by hydraulic pressure. If 100% weld quality control is performed using non-destructive methods, then hydraulic pressure testing may not be necessary.

The galvanized pipe is checked for the thickness of the zinc coating in accessible places inside and on the outside. In this case, 2 products from the batch are selected.

If the test results are unsatisfactory for at least one indicator, then it is necessary to re-test it for a 2 times larger sample. Repeated results apply to the entire batch of communications.

Pipes are checked for compliance with the parameters selectively - two products from each batch are examined

Applied steel pipe test methods

Tensile testing is carried out in accordance with GOST 10006. Instead, it is permissible to control mechanical properties using non-destructive methods. Pipes are inspected visually. According to GOST 3845, hydraulic tests are carried out, communications are kept under pressure for at least 5 seconds.

Note! Check for bending of galvanized pipes is carried out before applying a protective coating.

Distribution tests are carried out on a conical shaped mandrel with a taper angle of 6 ° according to GOST 8694. Flattening tests must comply with GOST 8695. The weld is controlled by non-destructive methods in accordance with NTD. The thread is checked by gauge rings in accordance with GOST 2533. The curvature of the pipes is controlled by a test line (GOST 8026).

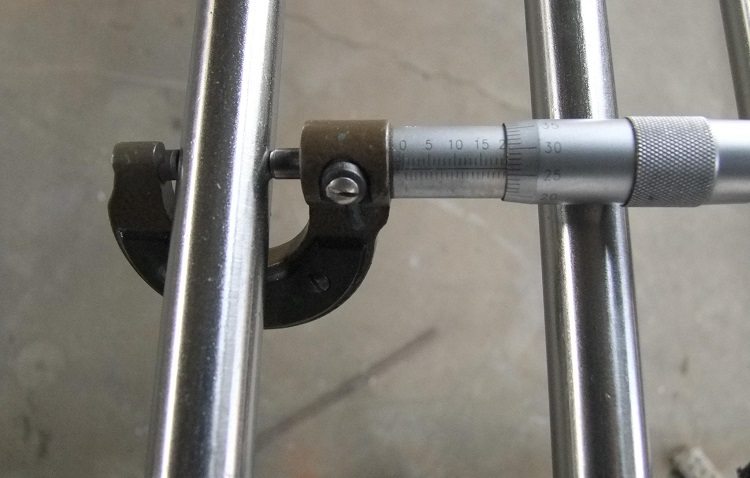

The rectangularity of the pipe end is checked with a 90 ° class 3 angle measuring 16 x 10 cm, the bevel angle of the chamfers with a goniometer, the outer diameter with a smooth micrometer and caliber brackets, and the length with a tape measure. The batch mass is controlled on a scale of not more than 10 tons and a division price of not more than 20 kg.

Due to its characteristics, steel VGP pipes are indispensable for almost any communication system. They are widely used in cases of impossibility of laying products from other materials.