Copper pipes are the most acceptable option for organizing a water supply network. The presence of various impurities in water does not affect the structure of such products. Due to their properties, they can be actively used in heating, air conditioning and gas transmission systems. The connection of pipes during installation is performed by crimp fittings or by soldering.

Content

Features of copper pipes

Important advantages of copper communication networks are high strength, corrosion resistance, flexibility and ductility, and long service life. An important feature of copper is the ability to eliminate certain bacteria, which prevents their reproduction and settling on the inner surface of the pipe.

When installing the pipeline with your own hands, it is necessary to take into account such selection factors copper pipes:

- purpose of the pipeline;

- temperature of substances to be transported;

- pressure in the water supply or heating system;

- pipe size;

- the presence of an insulating layer.

The disadvantage of copper pipes is low compatibility with products made from other materials.

The most important characteristic that determines the technical parameters of the pipeline and the selection of the necessary fittingsis the diameter of the copper pipe. In the construction of household systems, the most common are the following sizes:

| Pipe diameter mm | Wall thickness mm |

| 10-28 | 1 |

| 35-54 | 1,5 |

Important! With a smaller thickness, copper products have a much higher working pressure than steel counterparts.

More bulky systems involve the installation of large copper pipes.

Scopes of use of copper pipes

Due to the ability to work with high-temperature fluids, copper pipes are widely used in heating systems. This is especially important in single-tube schemes, where to maintain the temperature of the last radiator about 70 ° C, in the first it should be at 120 ° C. The maximum working temperature for polymer products is 95 ° C, while copper pipes can transport liquids with a temperature of 300 ° C.

A pipeline of this material can withstand a pressure of 200-400 atm. The solder joint does not lose tightness.

Soft copper pipes can easily carry up to 4 freeze / thaw cycles. Plumbing copper is resistant to chlorine. Being a strong oxidizing agent, it promotes the formation of an oxide protective film on the inner wall of the copper pipe, which increases the operating life of the pipeline.

With your own hands, a hidden laying of a copper pipeline can be performed if there is a polymer layer on it, which will prevent the flow of stray currents. It is also necessary to avoid the combination of materials in the system, which can lead to electrochemical corrosion. When connecting, for example, copper with aluminum, brass adapters are used.

Installation Tools

The main operations that are performed during the installation of copper pipes include cutting, bending, assembling components and joints, soldering, crimping, welding. Additionally, calibration and stripping of the ends, removal of burr and burrs, application of flux with the subsequent removal of its residues, etc. are performed.

Note! Before starting work, a water supply scheme is drawn up indicating the number of necessary parts and pipe sizes.

To install copper pipes with your own hands, you will need such tools:

- pipe cutter or hacksaw;

- manual calibrator;

- torch for soldering copper pipes;

- spanners;

- file.

Of the materials directly required are copper pipes, fittings for them, a tape that seals the threaded connection, flux and solder.

Before installation, it is necessary to prepare the necessary segments of copper pipes by cutting them with a pipe cutter. If a hacksaw is used for these purposes, it is important to put a new blade. Products are checked for integrity, damage, kinks, flattened sections, etc. are unacceptable.

The burner is needed if the connection is to be soldered. To connect to the cylinder with it, hoses must be included in the kit. Wrenches are required for threaded connection of copper pipes. The burrs are removed with a file.

Features of installation operations

The pipe cutting operation is simple and fast. Pay attention to maintaining the perpendicularity of the pipe axis and the cutting edge. The permissible deviation of the cut plane from the perpendicular to the pipe axis should be less than:

| Outer diameter mm | Cut bevel, mm |

| 6-18 | 2 |

| 22-42 | 3 |

| 54-76 | 4 |

| 88-108 | 5 |

The most common are disk pipe cutters. When using them, it is better to increase the speed than to apply more force. Sometimes, when cutting soft copper pipes, their ends are deformed, as a result, the mounting gap changes and the capillary effect is violated. To restore shape, the ends of the pipes are calibrated. First, the inner diameter is calibrated, then the outer.

The influx of metal during soldering - grata - can form inside the copper pipe, which will increase the resistance of the liquid during operation. In this case, you need to delete it.

Due to their ductility, copper pipes can be joined in a bell-shaped manner without the use of fittings or couplings. It is applicable only for pipes with equal diameters and in heating and water supply systems with water temperatures up to 110 ° C. Getting a bell is possible with the help of special tools.

When bending a copper pipe with a diameter of up to 15 mm, its radius must be at least 3.5 diameters, for diameters of more than 15 mm - four diameters. When manually bending, the permissible radius is 8 workpiece diameters, therefore, for copper pipe bending a pipe bender is used over a large radius.

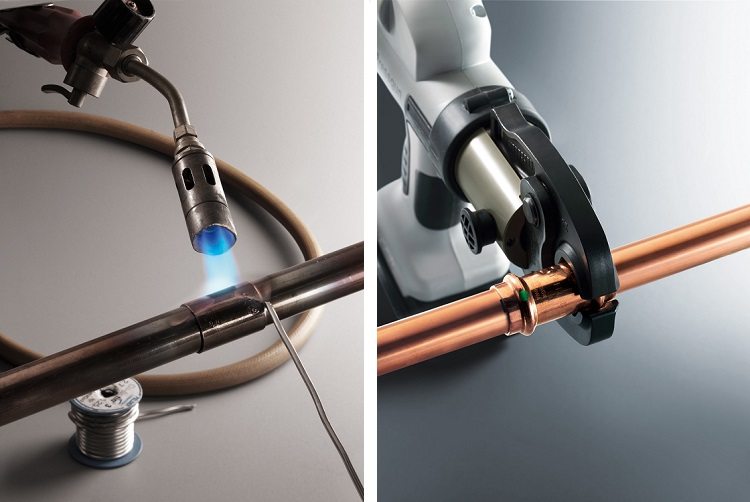

Threaded connection of copper pipes

When installing copper pipes with crimp fittings, collapsible joints are obtained that do not differ in absolute reliability and require monitoring during operation. Such a connection is designed for lower permissible pressure and needs periodic pull-ups. To begin with, a part of the pipe of the required length is cut. If copper pipes with an insulating layer are installed, then it is removed from the end of the product. To do this, an incision is made with a sharp knife and the insulation is removed. Further, the burrs are removed from the end of the pipe with a file.

First, a union nut is put on the pipe, and then a crimp ring. After joining the nut and crimp fitting, the threaded connection is tightened. First you need to do this smoothly, then use the key. During this process, the ring compresses the copper pipe and the joint is sealed.

In case transition fittings from steel pipes to copper are used, sealing is performed using fum tape. It is screwed onto the thread, and then the fitting is screwed in.

Important! Connection by crimp fittings is advisable in places where it is possible to check its tightness.

Features of soldering

Solder joints are used in situations where the installation of water supply or heating pipes is carried out in walls, floors or other options in which access is not possible for visual control of the integrity of the joint.

The method is based on the capillary effect, due to which the solder is evenly distributed over the pipe section, regardless of its position. To create it, special fittings are used, which have diameters that differ from the pipe diameters by a certain value. The recommended clearance for soldering over an open flame is 0.1-0.15 mm.

Solders and fluxes are used to connect using capillary soldering. There are low and high temperature soldering methods.

Soft (low temperature) soldering It is used for transportation networks of gaseous and liquid media with a working temperature of not more than 110 ° C. It is applicable for connecting pipes with a diameter of 7-110 mm. Products with a wall thickness of more than 1.6 mm and a diameter above 110 mm can be joined by welding.

Hard (high-temperature) soldering is almost not used when installing the pipeline with your own hands. It is applicable for connecting pipes in systems where operating conditions are associated with significant temperatures.

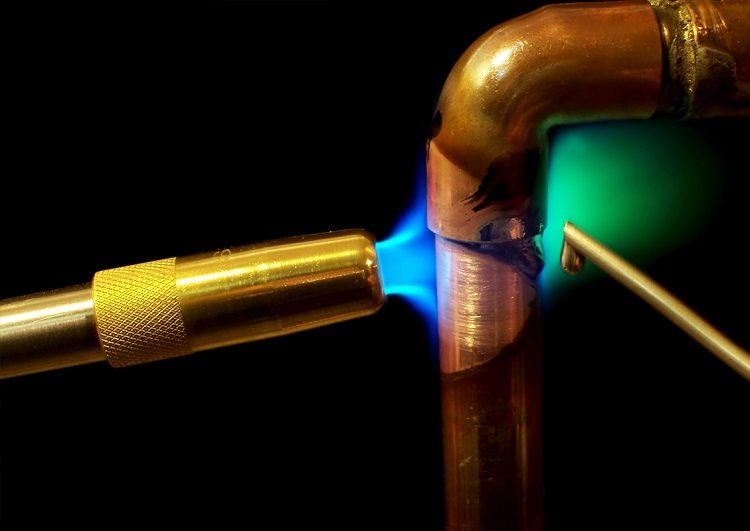

DIY soldering process

The soldering process is performed in the following sequence:

- Part of the pipe is cut to the required size.

- At its end, the insulation is removed and the burrs are removed.

- The soldering place and fitting are cleaned with an abrasive cloth from oxide film.

- The dust is wiped and a flux is applied to the surface.

- The end of the pipe is inserted into the fitting, leaving a gap of not more than 0.4 mm.

- Connection is warming up burner and the seam is sealed with solder.

If there is no burner, then a blowtorch is suitable for heating. The movement of the flame must be uniform so that individual sections do not overheat. Solder for brazing copper pipes should have a minimum melting point.

Helpful advice! To check the sufficiency of heating the connection, you need to touch the solder. If it melts, then the required temperature is reached.

In order to solder the seam into the gap between the pipe and the fitting, solder is introduced. It is important to ensure fixation and immobility of the compound until it crystallizes completely.

Thus, the installation of copper pipes can be done with your own hands, given all the rules and recommendations. The water supply system of such materials is characterized by durability and reliability.