Installation of water supply and sewage is a set of operations, as a result of which the stay of people in the building becomes quite comfortable, meeting the minimum requirements of modern civilization. The emergence of new materials and tools, technologies related to their use, made it possible to turn the process of installing water pipes into a feasible one for doing it yourself.

Installation of a water supply system can be easily done with your own hands, if you follow the established rules

Content

- 1 Classification and composition of water supply and sewage engineering networks

- 2 Stage-by-stage scheme of conducting water supply and sanitation

- 3 Choosing the option of arranging the layout of the internal water supply

- 4 How to choose pipes for autonomous water supply and sewerage

- 5 How is the installation of internal and external water and sewer networks

Classification and composition of water supply and sewage engineering networks

The water supply system is installed to ensure a continuous supply of usable water to the water intake point. Sewerage is equipped to divert used water and treat sewage. Arrangement of water supply and sanitation pipelines for an individual building or complex is possible in two ways:

- By connecting to a centralized system.

- By constructing an autonomous installation.

Depending on the method of moving the working medium, water supply and sewage networks can be:

- pressureless. Since it is intended to move the working medium by gravity, the pipelines are installed with a certain slope, allowing the fluid to flow without additional pumping;

- pressure head. With pumps ensuring constant movement of the working medium, the network is provided in cases when it is necessary to supply it in large volumes, as well as in difficult terrain, which does not allow the installation of an external water supply with an optimal slope.

Based on the location of the engineering networks in relation to the binding objects, it is customary to talk about them as:

- about internal. Installation of the internal water supply system begins from the place of introduction of the pipe into the building, the internal sewerage network ends at the point where the pipe leaves the building;

- outdoor. Installation of external water supply and sewage networks takes place outside of buildings and structures.

The internal water supply network consists of the following elements:

- entering the pipe into the building;

- launch water metering and dispensing installation;

- a source providing hot water;

- a double pipeline, which separately transport hot and cold water;

- inlets to points of drawoff;

- water consumers.

Internal sewerage networks are composed of:

- pipes leading from water points;

- sewer riser with pipes connected to it;

- the place of withdrawal from the construction of the sewer pipe.

Installation of external networks, plumbing and sewer, suggests that the installation of such equipment will be carried out:

- pumping (surface, submersible and / or fecal pumps);

- pipeline outside of buildings;

- wells (overflow, rotary, revision);

- wells (wells) required by the autonomous pipelines;

- sewage treatment plant, which requires sewage.

Stage-by-stage scheme of conducting water supply and sanitation

Installation and replacement of water supply and sanitation involves a certain sequence of actions, which can be schematically presented in the following form:

- Drawing up a plan and diagram, taking into account the location of the network and each element in detail.

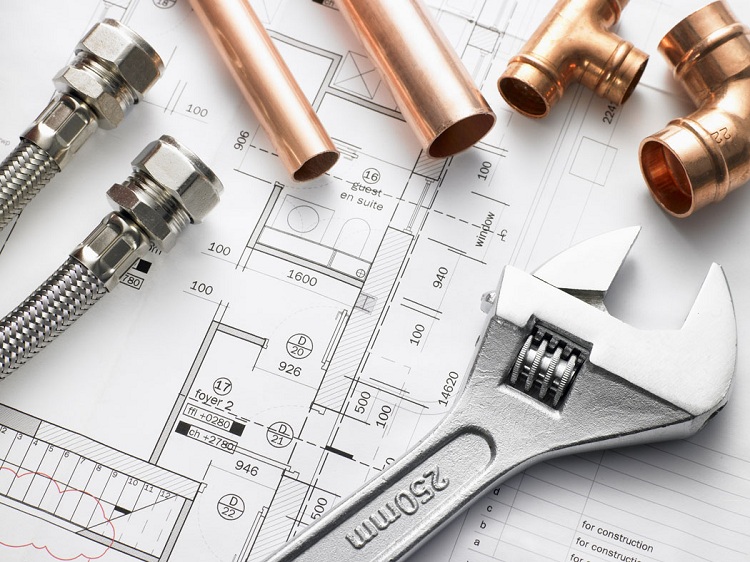

- Preparation of tools required during installation, selection of materials suitable for installation on the internal water supply and for the installation of an external network.

- Removing obsolete replacement devices.

- Conducting earthwork to lay outdoor communications at the required depth.

- Installation of water supply and sanitation pipelines for external networks.

- Restoring the normal appearance of the site on which the work and landscaping were carried out.

- Connection to internal networks. The transition to the installation and replacement of individual devices related to internal networks.

Before you begin any work, you need to draw up a diagram of the future pipeline and determine the type of material for its installation

Important! The foundation device for laying water and wastewater pipes and backfilling is given special attention to prevent incorrect operation and defrosting of systems.

Choosing the option of arranging the layout of the internal water supply

It is desirable to lay the internal water supply in such a way that its length is the smallest, and the project minimally contains turns and intersections. Installation of water supply pipes inside the building in a closed way is quite difficult. This requires certain professional skills and accurate preliminary calculations.

Note! There should be no fittings in the pipes hidden in the walls, and the connections made should be routed to areas accessible for inspection and prevention and repair work.

In an open way, the installation of the water supply system inside the building is much simpler, and the implementation of prevention, maintenance and repair will not cause any difficulties. The placement of water pipes in a vertical plane is provided in the corners of the premises, in the horizontal plane they are placed at floor level, at a small distance from the walls.

Water supply wiring is performed by:

- Sequentially. With a tee system, the pipeline coming from the main line is sequentially supplied to consumers. Through two pipes extending from the riser, on which there is an introductory locking device, hot and cold water is supplied to all consumers by means of tees. The advantage of serial wiring is the extreme ease of installation and the economical use of materials. A significant drawback is the possibility of a noticeable pressure drop in the system with the simultaneous connection of several consumers. As for the need to turn off the system as a whole for repair work, it is easy to avoid. For this, shutoff valves are installed on each branch.

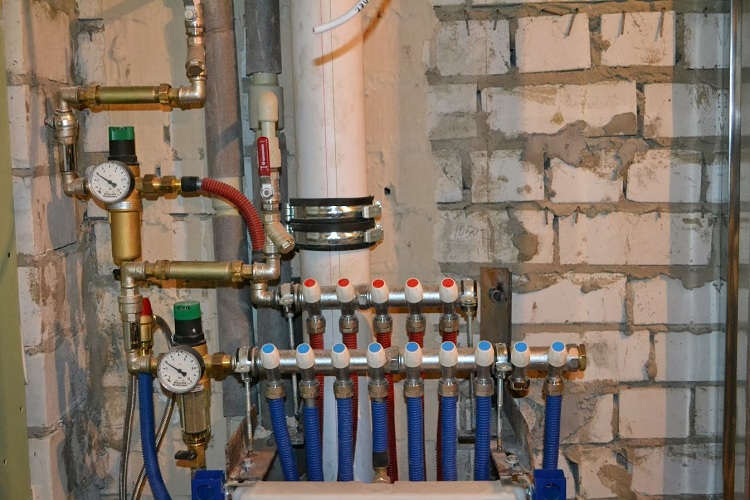

- Parallel. The collector system provides for the presence of the same device. It has one input, and the number of conclusions corresponds to the number of draw points. The advantage of parallel wiring is the uniform distribution of water between consumers, as well as the ability to perform maintenance and repair, disconnecting from the system only the area requiring attention. Another significant plus of the collector system is the concentration of all control devices in a single collector cabinet. The disadvantages include an increase in the complexity and cost of work and the system as a whole.

How to choose pipes for autonomous water supply and sewerage

Steel products for autonomous water supply and cast-iron are used less and less for sewage due to their significant weight and the relative complexity of laying, as well as their considerable cost. Without dwelling on the shortcomings of metal products in more detail, we note that consumers vote with their own wallets, and their preferences seem quite justified.

Copper is expensive, their installation will require the involvement of specialists. The aesthetic attractiveness of copper products is undeniable, and the durability of operation is subject to fairly reasonable doubts.

It is simple and convenient to work with metal-plastic water pipes. They are easily bent without the use of tools, can be connected by adapters with products from other materials. Assembly requires the use of fittings, the gaskets of which periodically need to be replaced, so a closed metal-plastic gasket is undesirable.

Good to know! It is recommended to use metal-plastic only in selected areas with open access, where its best properties are manifested - a low coefficient of hydrodynamic resistance and a small pressure loss of the working medium.

Now almost always the choice is in favor of one of the varieties of plastic:

- polyethylene. Strong and flexible polyethylene products equip the water supply system and the external sewer. Polyethylene joined by welding is not afraid of freezing followed by defrosting. Cross-linked polyethylene is of higher quality and cost, it is connected by fittings. Use is possible even for hot water supply and in heating systems;

- polyvinyl chloride. Rigid products bonded by bonding, UV resistant, suitable for open laying;

- polybutylene. Sufficiently expensive pipes are connected by welding, using their elasticity and thermal conductivity in warm water floors;

- polypropylene. The characteristics are similar to those of cross-linked polyethylene, but the cost is much lower. The use of special equipment for welding with exact adherence to the technological process allows to achieve a high duration of operation, not less than fifty years. The closed laying method is not recommended due to the high coefficient of thermal expansion.

Plastic water pipes preference is given due to such factors:

- long term of operation;

- diverse assortment;

- the possibility of laying both open and closed;

- inertness to corrosion and reactive substances;

- strength;

- low weight;

- reduced thermal conductivity;

- low roughness, providing high throughput and preventing the formation of plaque and blockages;

- simplified installation, maintenance and repair work.

When using plastic products, you should remember about their inherent shortcomings:

- flammability;

- loss of strength with increasing temperature;

- high coefficient of thermal expansion, manifested in deformation during operation.

The disadvantages of plastic pipes are considered insignificant in comparison with the benefits derived from their use. Therefore, in the vast majority of cases, preference is given to plastic products when installing sewage and water pipes. In this case, you should follow these tips:

- with a straight section length exceeding three meters, it is desirable to use welded or finished ring expansion joints;

- movable supports are used by attaching plastic pipes to the ceiling and walls, and fixed ones - for fastening gate valves, taps, counters, etc .;

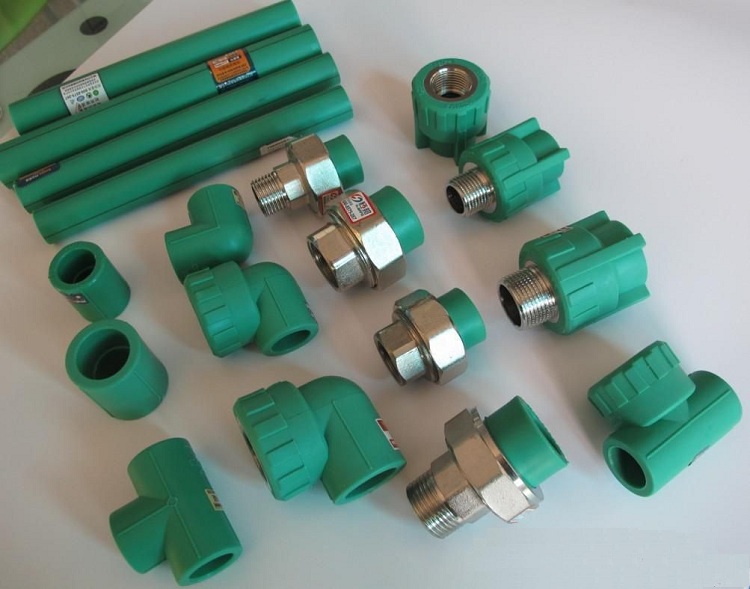

- connecting plastic pipes and metal parts, resort to the use of combined detachable fittings having metal inserts;

- tightening of threaded connections is carried out without excessive efforts so as not to push a metal insert out of the fitting;

- on a threaded connection, the sealing winding is applied sparingly;

- fixing supports should be resorted to at a minimum, and the step between the sliding is equal to one meter.

To connect polymer pipes, different types of fittings are used, including combined fittings with metal elements

How is the installation of internal and external water and sewer networks

Having worked out the project and selecting the required materials and tools to carry out the installation, you can begin to implement it. By laying internal networks, as a general rule, it is customary to do as the frame of the building is ready, when the construction of walls and roof is completed. When laying internal networks, it is customary to observe a number of rules:

- to introduce a water pipe into the building, observing the minimum one and a half meter distance from the sewer, gas and heating;

- the installation of the water meter assembly should be carried out at the place of entry, departing from the first outer wall;

- installation of a departmental valve blocking the water supply is recommended in front of the water meter, and installation of a house valve after the water meter;

- the diameter of the pipes is selected based on the number of consumers;

- during installation in the building, the pipeline is laid, as usual, in the basement;

- anticipating the lack of water pressure at the entrance to the building, provide for the installation of two separate pumps, operating, respectively, at low and high levels of water consumption, and the third - backup;

- pipe laying is carried out with a slope provided for in the project.

When laying external water and sewer networks it is accepted:

- set the depth of the pipes so that the pipeline passes below the line of seasonal freezing of the soil;

- lay a pillow of sand and gravel, preventing sagging pipes;

- to make layer-by-layer filling with ensuring hydro and thermal insulation;

- at the intersection of the water supply and sewer networks provided for by the project, lay pipes through which water is supplied, at least half a meter higher. At the intersection, install a steel casing extending in each direction to a minimum five-meter distance in clay soil and a minimum ten-meter distance if the soil is sandy. The angle of the intersection to be made straight;

- for parallel installation of water and sewer pipes with a diameter of less than 200 mm, provide a distance between the walls of at least one and a half meters;

- restore a layer of sod over trenches and improve the surrounding area.

The works associated with the installation and replacement of water and sewer communications have been greatly simplified with the distribution of plastic pipes and connecting elements for their installation. With low weight and low cost of materials, sufficient simplicity of equipment for their installation, work on laying autonomous internal and external networks has become quite possible on its own. Proper design of the project and the selection of materials, compliance with the details of the technological process will create comfortable conditions for staying in buildings. Independent installation of water supply and sewage systems, internal and external, using plastic pipes will ensure long-term reliable operation of the systems.