Corrosion-proof seamless pipe is a type of rolled pipe, which is obtained from stainless high-alloy steel and does not have a welded joint. The cross section of products can have a different shape: round, square, rectangular, oval, etc. A seamless pipe has the necessary strength, rigidity and durability, as well as an increased level of technical and operational characteristics.

Content

Types of Seamless Products

This type of metal is made of alloyed, carbon or low alloy steels. According to the production method, a seamless stainless pipe is:

- cold rolled;

- hot rolled.

In the second case, the workpiece is heated. A hot-rolled pipe has thicker walls, up to 32 mm, and a diameter of up to 32.5 cm. Cold rolled seamless products are thinner and come in smaller diameters.

Obtaining seamless stainless pipes is ensured by the production process with sequential execution:

- rental;

- pressing;

- forging;

- drawing

- centrifugal casting.

The scope of the product depends on the type of surface: unprocessed, mirror and polished. Seamless seamless pipes do not need to be painted or primed. Welded and seamless products by the value of the ratio of their wall thickness to diameter are classified as extra-thin-walled, thin-walled, thick-walled, extra-thick-walled.

According to the standards, 20 alloys with corrosion-resistant properties can be used for the production of seamless pipes.

Steel grades for seamless pipes

The most popular steel, characterized by corrosion resistance, which is used for the manufacture of pipes, is the grade 12x18n10t. It contains alloying agents such as chromium, titanium or nickel. Often, steel products of grade 12x18n10t are used when laying water pipes for hot and cold water, since they do not adversely affect the quality and composition of drinking water.

Note! The elongation of such pipes should be at least 40%, and the tensile strength - 529 N / mm2 (according to GOST 9940).

Such products may have a different cut shape. Non-circular sections are used to create various metal structures, for the production of interior items, as well as for the interior decoration of various premises.

Steel grade 10x17n13m2t is highly resistant to acidic media. This property is maintained during long-term exposure to temperatures up to 600 ° C. Pipes from this material are widely used in the chemical, food and medical industries. They are perfectly welded, forming a tight and reliable seam, which determines their long service life.

Steel pipes come in many different shapes and are even used as decorative elements in a wide variety of fields.

Products 06ХН28МДТ are used for long-term operation in metallurgy, petrochemistry, and in factories when working with acids under high temperature.

High alloyed steel 10X23H18 gives the pipes unique properties in terms of heat resistance and heat resistance. Such products are widely used in the production of combustion chambers, high-temperature pipelines, boilers and other equipment operating at temperatures up to 1100 ° C.

Product manufacturing steps

The technological process for the production of seamless pipes is very laborious and complex. It requires a significant expenditure of raw materials and energy. All substances used in it must be of high quality, since their properties and characteristics will be transferred to products. Also requires the cleaning of metal from impurities.

Pipes are manufactured on high-precision automated machines. At the initial stage, the workpiece is heated in a special furnace. After reaching the temperature of red heat, she goes to the press-piercing mill. To shape, special forming elements act on the workpiece. Hot metal processing does not imply tearing or deformation in the wrong direction. Cooling down, it will retain the resulting shape.

Next, the pipe is rolled to the required length, the formation of the inner, outer diameter and wall thickness. Products are cooled and calibrated in a special bath. Some pipes undergo an additional quenching process, in which they heat up and then instantly cool. This procedure leads to the restructuring of the molecular network and gives the necessary properties.

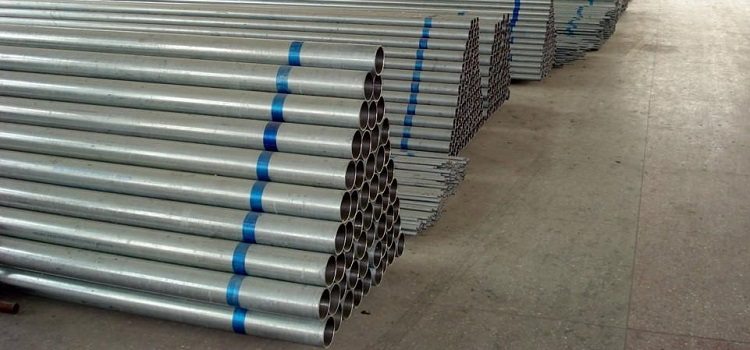

The production technology of seamless pipes is complex, time-consuming and requires the use of only high-quality raw materials

At the final stage, the pipes are cut into pieces of the required length and marked.

Pipe specifications

Seamless stainless steel pipes have high corrosion resistance and strength. Due to the absence of welded joints, they do not have local weld corrosion. Such pipes are much better than others, withstand high and high pressures, aggressive influences of the internal environment, and are also applicable in a variety of conditions (for example, at elevated or low temperatures, in rooms with high humidity).

Note! Corrosion-proof pipes do not oxidize. They do not affect the biological and chemical composition of the substances that are pumped through them.

Products are characterized by the ability to self-repair, if there is slight damage on their surface, as well as the inability to leak or escape volatile substances. Seamless pipe has several advantages over electric welded:

- different wall thickness depending on the type of pipe;

- lack of a seam - a potentially weak point;

- the same strength along the entire length.

To calculate the weight of a stainless pipe, a theoretical formula is applied, having the form:

M = l * (d-a) * ρ * π * a,

where l is the length of the pipe (meters); ρ is the density of stainless steel (7480-8000 kg / m3); d is the outer diameter (meters); a - pipe wall thickness (meters); π is the constant (3.14). The density of the 12X18H10T alloy is 7.9 g / cm3.

The seam is clearly visible on the welded pipe - the junction of the steel sheet, this trace is absent on the seamless pipe

Sizes of seamless pipes

Hot-deformed stainless steel tubes are made according to wall thickness and outer diameter according to GOST 9940-81, heat and cold-deformed products - GOST 9941-81. The assortment of these pipes is also determined by standards. The main difference between these two standards is the difference in the mechanical characteristics of seamless pipes, which are due to different methods of their manufacture.

Hot-deformed stainless products are made of such length:

- unmeasured: from 15 to 100 cm;

- dimensional: within the boundaries of non-dimensional, the maximum deviation up to +15 mm is permissible;

- multiple measured: within the measured limits, taking into account an allowance of 5 mm per cut, a maximum deviation of up to +15 mm in length is permissible, the minimum value of a multiple length is 300 mm;

- limited: within the measured limits with an allowable marginal deviation of 500 mm up or down.

Hot-deformed, heat- and cold-deformed stainless pipes are made of steel grades, the chemical structure of which is consistent with GOST 5632. The introduction of rare-earth metal microadditives is allowed. The amount of sulfur contained in the steel used for the production of pipes should not be more than 0.02%.

Heat-deformed and cold-deformed stainless pipes are made of unmeasured length with the values presented in the table.

Table 1

| Wall thickness in mm | Minimum length, m | Maximum length, m |

| up to 0.5 | 0,75 | 7 |

| 0,5-1,0 | 1,0 | 7 |

| more than 1.0 | 1,5 | 12,5 |

The release of products of unmeasured length and multiple measured is similar to the requirements for hot-deformed pipes.

Seamless pipes are supplied in segments, the length of which depends on the thickness of the walls of the product

Requirements for stainless steel products

Regulatory documents determine that a stainless seamless pipe made of steel 12x18n10t must have a yield strength of at least 216 MPa and a density of 7.95 g / cm3. In the alloy, it contains titanium, which gives excellent anti-corrosion properties, and the carbon contained can significantly increase the hardness of the product.

Note! The minimum wall thickness of hot-deformed products can be 0.12 mm, according to GOST 10498-82.

The requirements for the length of particularly thin-walled pipes are given in the table.

Table 1

| Diameter in mm | Minimum length, m | Maximum length, m |

| 4-6 | 0,5 | 3 |

| 6-25 | 0,5 | 5 |

| more than 25 | 0,5 | 4 |

Corrosion-proof pipes can work at temperatures of internal liquid in normal conditions up to 800 ° C, in aggressive environments - up to 350 ° C. Also, the characteristics depend on the elemental composition of the steels: cold-resistant, impact-resistant, heat-resistant stainless, carbide, etc.

Regarding the curvature of the rolled pipe, then in any section 100 cm long it should not be more:

- 1 mm (for pipes of any diameters with a wall thickness of half a millimeter or more);

- 2 mm (for pipes with a diameter exceeding 15 mm and a wall thickness of less than half a millimeter).

Cutting products should be carried out at right angles with the obligatory cleaning of the ends from burrs. The outer and inner surfaces should not have cracks, flaws and sunsets. It is necessary that the pipes have a light color.

Seamless pipe application

Stainless products have specific qualities, the formation of which occurs using different processing methods. These include, for example, rolling pipes that are hot, and subsequent heat treatment, cold deformation with imparting strength, etc.

Stainless steel is a very durable and practical material that does not rust and does not tarnish over the years. All parts and structures made of it have long-term operational periods. Thick-walled pipes have a wide range of applications, including the following areas:

- details of gas and oil pipelines for the oil refining and petrochemical industries;

- pipes of steam pipelines of condensing power plants, high-pressure steam boilers;

- bimetallic pipes having an internal wear-resistant layer for the transportation of pulp containing diamonds, hydrotransport of ore materials, as well as the production of pump parts;

- pipes used in construction.

Thin-walled products are used:

- in food production, which have high hygienic characteristics;

- in medicine;

- ship, auto and aircraft industry;

- for supplying hot and cold water;

- in heating systems.

Also, a seamless pipe can act as a design item or furniture elements.

Seamless pipes are connected by welding, but if necessary, threads are cut into it; such a connection requires sealing

Types of joining stainless steel pipes

Seamless stainless steel pipes are connected by welding, which can be automatic, semi-automatic and manual. Several technologies exist: TIG, HF and Laser. The first option is welding with an tungsten electrode in an inert gas environment. The resulting seam is characterized by density, uniformity, the absence of shells and voids. The strength of the weld is not inferior to the main material.

Note! The heat generator, which is necessary for welding, is an arc formed between the product and the electrode. Gas enters the weld zone from inside and outside the pipe, which protects the seam from oxidation.

HF - high-frequency current welding, which allows you to get a seam with slightly lower strength characteristics than that of the pipe body. This is explained by the limited melting zone and the absence of a thermal irritation zone, which leads to heterogeneity of the weld. This technology is less expensive.

Laser welding technology allows you to save the strength characteristics of the TIG weld, as well as reduces the melting zone, resulting in better surface treatment of the weld. This is important for pipes used in the chemical and food industries. Typically, laser welding is used in combination with TIG and plasma welding.

The popularity of seamless stainless steel pipes is explained by important operational parameters, extended temperature limits of their application, and high strength properties.