Annealed copper pipes are widely used in water supply and air conditioning heating networks due to their high degree of thermal conductivity, bactericidal properties and corrosion resistance (with the exception of very chlorinated water or acidic media). Plasticity and the ability to take a variety of forms greatly simplifies the process of installation.

Content

What is a copper pipe

Copper pipes are available in two types: annealed and unannealed. The initial stage of production is ore processing. Further, through the so-called blister copper obtained, oxygen is blown, which burns out impurities. As a result of this procedure, metal ingots having a purity of more than 99% are obtained.

Unbaked pipe is produced from such ingots. The processes of rolling, stamping lead to a loss of material elasticity, but at the same time a significant margin of safety is acquired. For an unannealed copper pipe, the tensile strength is 340-450 MPa, and the allowable tensile product is up to 6%.

The annealed pipe is obtained as a result of the heat treatment (annealing) process. The temperature of such heating is about 700 degrees. After gradual cooling, called vacation, the product acquires all the required characteristics.

Note! The strength margin of the annealed copper pipe is 220 MPa, but its elasticity increases several times - elongation of 1.5 or more times is possible.

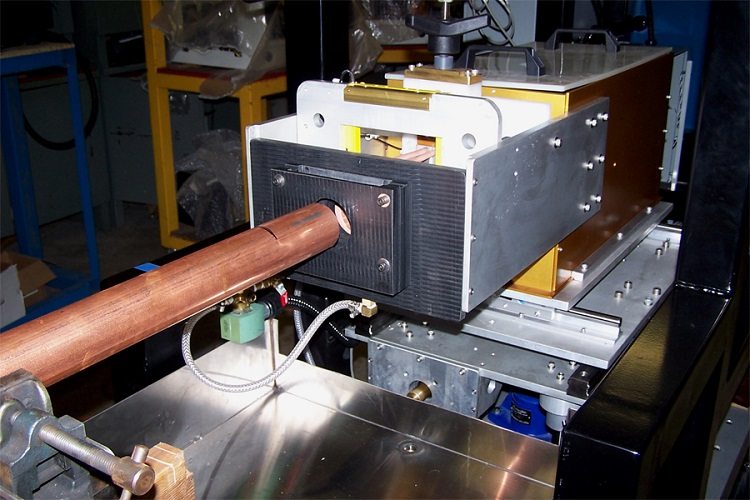

In order for the pipe to acquire special properties, it is subjected to heat treatment on special equipment

An unannealed pipe does not undergo such heat treatment, so the internal structure of the metal remains unchanged.

Advantages and disadvantages of copper products

Annealed products are resistant to high humidity, frequent and sudden changes and temperature jumps. Thick-walled copper pipe can withstand almost any pressure.

Modern production technologies involve the application of an external polymer layer, which can reduce heat loss. This solution is important for the use of copper pipes in hot water and heating systems. The outer coating also prevents condensation.

Copper products have a smooth inner surface, which allows to maintain good passability during the entire period of operation. They have excellent heat resistance. Even a thin-walled pipe can withstand high temperatures without deformation.

For annealing, a special inert composition is used. Such a measure ensures the resistance of pipes to ultraviolet rays, various aggressive substances, for example, alkalis, acids. The annealed pipe does not lose its technical characteristics when water freezes in it.

Copper pipes can be connected by soldering or fittings, but each of the methods is quite laborious and requires strict observance of installation rules

Among the shortcomings, a rather high cost of products and the complexity of installation work are distinguished. In addition, small mechanical impacts on thin-walled copper pipes can lead to their deformation.

Characteristics of annealed and unannealed pipes

Copper pipes are subject to several regulatory documents. The content of impurities is determined by GOST R 52318-2005 and should not be more than 0.1%. The assortment of copper pipes is regulated by GOST 617-90, which determines the use of copper grades M3r, M3, M2r, M2, M1r, M1. Products may be:

- solid;

- semi-solid;

- soft.

The standard distinguishes cold-rolled, drawn and pressed copper pipes. The main requirements that are regulated by the document relate to the condition and shape of the products. Plumbing annealed and unannealed pipes should not have external and internal defects.

Note! The destruction of the annealed pipe occurs at a pressure of 200 atm.

It can be operated in a wide temperature range - from +250 to -200 ° С. Such indicators relate to the parameters of the coolant and the environment.

An unannealed pipe, when trying to bend it, can be permanently deformed, therefore such products are delivered in straight sections. Annealed options are often delivered in bays.

The annealing stage gives increased ductility to the copper pipe, which means the appearance of a possible rupture when it is elongated by 60%. The service life of copper products is up to 100 years.

Carrying out the necessary calculations

At pipeline installation often there is a need to calculate various parameters or determine the amount of additional materials required. To calculate the weight of a copper pipe, the expression has the form:

M = L * ρ * π * b * (d-b),

where L is the pipe length (in meters), ρ is the copper density (8930 kg / m3), π is the constant (3.14), b is the pipe wall thickness (in meters), d is the outer diameter (in meters).

When using copper pipes in a heating network, their thermal insulation is necessary, since a high coefficient of thermal conductivity leads to significant heat losses. For this, ready-made covers are used. If thermal insulation is carried out with other materials, the question arises of their sufficient quantity.

The expression for determining the area of the side surface of the pipe has the form:

S = 2 * π * r * L,

where r is the outer radius, L is the length of the pipe.

The cross section of the pipe is most often given in fractions of an inch. There is no need to use a special expression to select a suitable part; you can refer to the table data.

Table 1

| Cross section in fractions of an inch | Wall thickness in mm | Outer diameter in mm |

| ¼ | 0,6 | 6,4 |

| 3/8 | 0,7 | 9,5 |

| ½ | 0,9 | 12,7 |

| 5/8 | 1,02 | 15,9 |

| ¾ | 1,02 | 19,05 |

| 7/8 | 1,1 | 22,2 |

| 1 1/8 | 1,3 | 28,6 |

| 1 3/8 | 1,4 | 35,0 |

| 2 1/8 | 1,78 | 54 |

| 2 5/8 | 2,03 | 66,7 |

| 3 1/8 | 2,5 | 79,4 |

| 4 1/8 | 2,8 | 104,7 |

There is another important formula that allows you to determine the permissible pressure in the pipe. For hollow thin-walled cylinders, the expression has the form:

P = 2 * s * b / d,

where s is the permissible voltage for long-term continuous operation of the pipe, b is the wall thickness, d is the outer diameter.

Copper pipes can withstand high pressure and high temperature, therefore, they are often used for installation of heating systems

Application of plumbing copper pipes

Since the unannealed pipe has a significant margin of safety, it is used in the manufacture of automotive parts, equipment for refrigeration structures and hydraulic units. Often, such products are used for the installation of hot water supply in places where water is heated to 100 ° C when supplied, for example, in a boiler room, laboratory, or industrial enterprise. An unannealed copper pipe does not become clogged with debris and deposits.

Note! In hot water networks, it is better to use detachable connections, rather than soldered ones, for joining the elements together. This is due to the low melting point of the solder and the destruction of the compound when exposed to hot water.

If a thin-walled copper pipe is part of a different system, then capillary soldering, welding or application is quite suitable for the connection fittings.

Annealed pipe can be used both in industry and in everyday life.Since it is thin-walled, that is, it is possible to reduce the size of the inner diameter without reducing its throughput and strength.

Products less than 10 mm in diameter are used to arrange internal heat exchangers for air conditioning and heating systems. Efficiency of operation is ensured by good energy transfer. Pipes with a diameter of 10-25 mm are usually part of plumbing systems.

In drain systems, varieties up to 4-4.5 cm are used. The efficiency of water disposal is ensured by high traffic. Thicker pipes are suitable for heating systems. A thin-walled pipe, together with high heat resistance of the material, heats the room with low energy consumption.

In this way, copper products They have favorable technical characteristics, a wide range of products, which means that almost any plumbing system can be organized on their basis.