Large-diameter pipes are products that are made from various materials and are used for laying trunk pipelines transporting oil products, gas, hot and cold water, and wastewater. Large-diameter pipes, as a rule, transport the working medium over considerable distances.

Content

Features and characteristics of pipes with a large diameter

Pipes with large cross-sectional indicators are operated not only during the installation of trunk lines, but also for other tasks. One of these tasks is to strengthen the walls of wells that extract minerals. Such products are used in utilities for various purposes.

Note! The cross-sectional indicators of the main pipes are the main feature that determines their operational area. The outer diameter of these parts can vary from 530 to 1420 mm.

Products that are used to reinforce well walls have more modest cross-sectional indicators. The largest "representatives" of this class reach an outer diameter of not more than 508 mm. The material from which the trunk and casing parts are made may be different, however, the products from:

- steel;

- modern polymer materials.

Half a century ago, parts made of concrete and various metals: iron, cast iron, steel, were used to lay trunk communications. However, with the development of industry, many new materials have appeared, which are made from various polymers and additives to them. Plastic pipes have many advantages and today are used almost everywhere.

Large diameter steel pipes

Today, steel pipeline elements occupy a leading position in the market of building materials used for the installation of highways. Despite the fact that their cost is quite high (compared to plastic counterparts), the demand for them is incredibly high.

Consider the main operational industries of steel products, characterized by large cross-sectional indicators:

- gas and oil pipelines;

- as casing pipes for wells;

- thermal pipeline structures;

- water pipes;

- sewer communications.

Operating pressure in the lines that transport oil and gas, as a rule, reaches high rates. Steel products are characterized by good strength characteristics and are able to withstand very high pressures, so they are suitable for such purposes.

There are three main types of steel parts that are classified according to manufacturing technology. Consider them:

- longitudinal welded by means of electric arc welding. Such products have cross-sectional indicators from 530 to 1420 mm;

- spiral seam produced by electric arc welding. They have cross-sectional indicators from 159 to 820 mm;

- longitudinal welded parts made by resistance welding.They differ in small diameters (114–530 mm).

Helpful information! Steel straight-seam products made by electric arc welding have a different number of seams, depending on their cross-section. Parts with a diameter of up to 820 mm are distinguished by the fact that they have one transverse and longitudinal seam, and with cross-sectional indicators above 820 mm, one transverse and two longitudinal ones.

All electric-welded products with straight seams are classified by the method of deformation into:

- cold rolled products;

- hot rolled products.

Varieties of shells of steel pipes

Steel products with high cross-sectional indicators are used in difficult conditions. High pressure in the communication, low temperatures and the harmful effects of corrosion can damage the pipe. In order to protect the pipes from these negative factors, they are usually insulated with various materials.

Consider the two most popular materials used to isolate steel trunk communications:

- polyurethane foam equipped with a special sheath made of polyethylene (for waterproofing). In abbreviated form, this insulator looks like this: PPU-PE;

- polyurethane foam, which has a shell made of galvanized steel (PPU-OTs).

PPU-PE

PPU-PE has a low coefficient of thermal conductivity. This insulator is an excellent protective option if the main pipeline construction is laid at low temperatures. Installation of PPU-PE is quite simple. The steel pipe is located in a polyethylene. Between the outer shell of the steel part and the inner shell of the PE product there is a space that is filled with polyurethane foam. Polyurethane foam is applied under high pressure and hardens. The result is a “pie” of pipes and heat-insulating material between them.

It is worth noting that such a protective case is very effective and eliminates the use of additional concrete boxes. Consider the main methods of laying devices with PPU-PE insulation:

- internal laying (underground). Moreover, such products are used both for underground channelless installation and channel installation;

- external laying (aboveground).

Through such methods, communications are installed that transport hot and cold water to consumers. These options are popular when installing heating systems.

PPU-OTs

PPU-OTs is a zinc layer that is located inside and outside the main steel part. The empty space between them, as in the previous case, is filled with polyurethane foam. Zinc is an excellent anti-corrosion material. Its use allows you to protect the pipe from corrosion damage and extend its service life by several times.

Depending on the wall thickness, pipes in such insulation are divided into three main types:

- lungs;

- ordinary;

- heavy (reinforced).

Such products are used during the installation of water and gas main lines.

Large diameter polymer pipes

Modern polymeric materials are used in almost all spheres of human activity. Large diameter plastic pipes are made from the following materials:

- polypropylene (PP);

- polyethylene (PE), including low pressure polyethylene (HDPE).

Polypropylene parts are used in gas pipelines and differ in cross-sectional indicators from 110 to 2400 mm. Products made of low-pressure polyethylene differ in cross-sectional indicators from 630 to 1200 mm and are used, as a rule, in the installation of sewer communications, which have small pressure indicators.

Consider the main advantages of polymer products:

- resistance to harmful corrosive effects;

- resistance to aggressive chemical compounds;

- good resistance to temperature fluctuations;

- low cost;

- light weight;

- ease of transportation and installation;

- durability (operational life of modern polymeric materials reaches 50 years).

Pipes made of polymeric materials have many positive qualities and are used in the same areas as steel

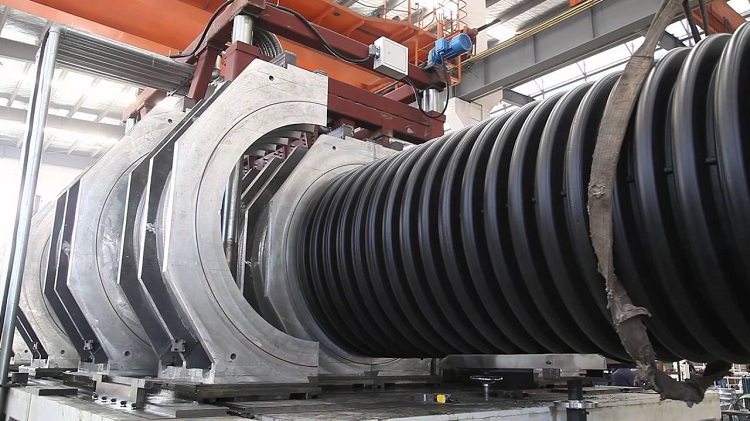

Spiral PE pipes of large diameters

Spiral products with large cross-sectional indicators are made of polyethylene and are used when laying gravity sewer communications, as well as during the installation of storm sewers. Previously, concrete pipes were used for these purposes. Today, polyethylene products are mounted instead of old concrete pipes or laid in them. In the second case, the old concrete structure acts as a protective case.

Note! Such pipes are used for tunneling under roads and railways. Such pipes are much lighter than concrete pipes (14 times), they are notable for their low cost and ease of installation, which allows to save and reduce labor costs to a minimum.

The operational life of such products can reach 100 years. From a constructive point of view, such details are unique in their kind, because they have a wound profile. This profile is rectangular in shape. This shape of the wound profile provides good resistance of the pipe to loads in the soil.