With the help of fittings of this type, a wide variety of tasks are solved. So, for example, when working with pipelines of the oil and gas industry, the use of plugs on steel pipes makes it possible to emergencyly block the passage of the working medium along the main or part of it, reliably block the end openings of the branches and branch pipes. In addition, they are used to ensure the safety of transportation of metal and as decorative elements.

Content

Types of caps for steel pipes

In today's market there is a wide variety of plugs for steel pipes. They are divided into types according to several criteria, the main of which are the design features of these elements and the material of their manufacture.

Threaded. They are intended for use in conjunction with pipelines and fittings on threaded connections. Installing such end caps is very easy. But in order to prevent breakdown of the area, the thread must be tightened securely.

Pneumatic Made of rubber. The pneumatic plug looks like a durable inflatable balloon with a compact pump attached to it. In the process of pumping air, the ball increases in size, as a result of which the hole in the pipe is completely blocked.

Helpful information! When carrying out repairs on damaged areas using pneumatic plugs, it is not necessary to shut down the main line.

Shipping. They are carried out in the form of a cap or a cover and have an integral very simple design. This technical solution is fully justified. Indeed, such end caps are used in order to simply block the pipes during their transportation.

Elliptical. The production of such steel pipe fittings is carried out by stamping from sheet metal. Being a universal part, an elliptical steel plug is used not only to close the end sections of pipelines, but also as a locking element of a container or vessel. As raw materials for their manufacture, 09G2S steel is used. The production process is regulated by the requirements of GOST 17379-01.

The most common types of elliptical metal fittings for steel pipes are presented in the table below. The diameter of the product is denoted by Dн., And its height is H. Unit of measurement ˗ millimeters.

| Size, DN x H | Stub designation |

| 530x16 | J396_P39_04 |

| 426x12 | J396_P39_03 |

| 325x12 | J396_P39_02 |

| 273x12 | J396_P39_01 |

| 219x10 | Ж396_Р39 |

| 159x8 | J396_P38_04 |

| 108x8 | J396_P38_03 |

| 89x8 | J396_P38_02 |

| 76x6 | J396_P38_01 |

| 57x5 | Ж396_Р38 |

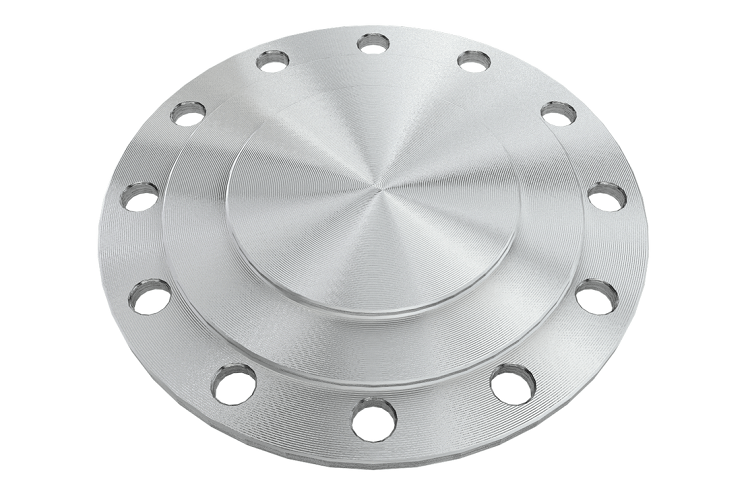

Flanged. Fittings for steel pipes this type in the form of a disk with a supporting annular surface in which holes are drilled for threaded connection to the pipe flange. They are used to block those pipeline branches, the use of which is not supposed to be further.

Compression. This is one of the varieties of crimp plugs. Compression locking element is equipped with a split ring and is designed for operation in an open area. Most in demand are parts with a diameter of 32, 26, 20 and 16 millimeters.Ease of installation is the undeniable advantage of compression fittings for steel pipes. In addition, they have the following advantages:

- they provide perfect joint tightness without additional measures;

- compression plugs can be reused while maintaining the quality of the part itself;

- the ability to install on pipelines made of various materials.

Compression fittings are also characterized by high technical performance.

Crimp. Due to the fact that using a crimp fitting for steel pipes a completely tight design is created, it is allowed to use such a locking element in communications made by the method of hidden laying. It should be noted that of the entire range of metal crimp fittings for steel pipes, the most universal are the parts that came off the assembly line of the German company Gebo-Armaturen GmbH. They are suitable for pipes made of black and galvanized steel, as well as for cast iron pipelines.

Of course, with the help of crimp locking elements it is impossible to jam profile pipes. But this should not be considered as their disadvantage. After all, they are used mainly not in water supply, but where it is necessary to create a rigid structure. So you can do without crimp plugs here. Moreover, today in the market you can find many samples designed specifically for killing profile pipes.

Helpful advice! After installation, be sure to check the connection for leaks and the integrity of the entire system.

Press fittings. Like compression, press fittings are one of the varieties of crimp locking elements. The popularity of such products is due to the presence of the following properties:

- during the installation of press fittings for steel pipes there is no need to use sophisticated welding equipment and use the services of an experienced welder;

- any owner of the house who does not even have special skills can drown out the dead end with the help of a press fitting;

- with the help of crimping press fittings, steel, metal-plastic, polymer, cast-iron and other pipes are suppressed;

- Compared to threaded fittings for steel pipes, the operation of crimping press dies does not require regular monitoring (of course, within reasonable limits, that is, sometimes it is necessary to check the place of muffling).

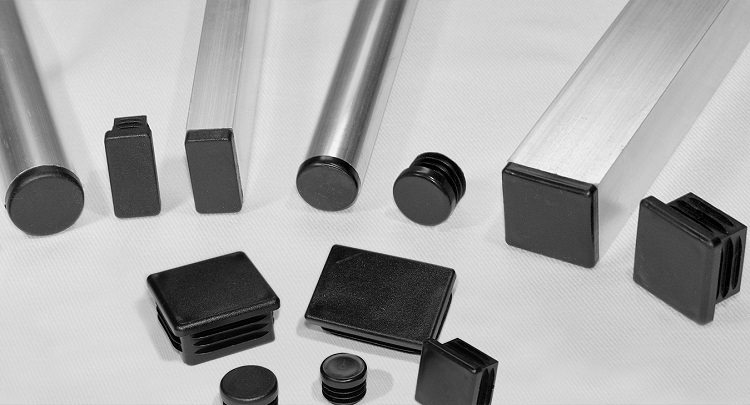

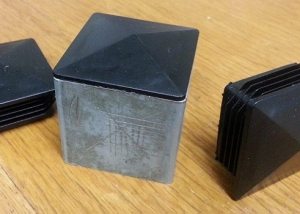

Butt. They are used to solve the simplest tasks, when it is simply necessary to cover the end of the steel pipe supports, that is, to create a barrier from the penetration of moisture and debris. In addition, such fittings for steel pipes are installed for decorative purposes. They are one of the varieties of transportation locking elements.

Cast Iron Plugs

As you know, in the world of plumbing, there has long been a trend of increasing popularity of polymer parts. But cast-iron threaded caps still occupy a decent niche in volume in this segment of the world market. However, you should be aware that they are not used in wastewater and sewage disposal systems.

In general, cast-iron locking elements have a number of undeniable advantages, the main of which are:

- high quality products. Intense competition forces manufacturers to pay increased attention to this issue;

- with the help of threaded cast-iron fittings for steel pipes, a high degree of tightness of the joint can be provided;

- simplicity of installation work (you can plug the pipe with your own hands);

- optimal price / quality ratio.

Cast iron plugs can be used repeatedly, it is convenient and practical.

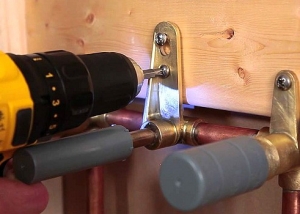

Installation example of cast iron products

The installation process of a threaded cast iron plug is as follows. At the end of the pipe, a thread is cut using a die. It is enough to make 7 turns. Any sealant is applied to the pipe thread. Then the coupling is screwed into the sealed threaded connection.

Before starting to screw the plug into the coupling, a sealant is also wound clockwise on its thread. After that, use the pipe wrench to tighten the plug into the sleeve until it is jammed.

Helpful advice! Do not overdo it when doing this procedure. Excessive force can cause the part to burst.

Cast iron plugs are uncoated (black) and zinc coated (galvanized). Being made of malleable cast iron, they are able to withstand high pressure in pipelines for a very long time. And thanks to explosion safety, such shut-off elements can be used not only in heating systems and water supply / removal systems, but also in gas supply.