GOST 3262 75 applies to galvanized and non-galvanized welded steel pipes without threads and with rolled or threaded cylindrical threads. The scope of their application is water and gas pipelines, heating systems, as well as the production of parts for gas and water structures.

Content

Assortment of water and gas pipes GOST 3262 75

In accordance with the requirements of this regulatory document, pipes are produced by weight and size specified in table No. 1. The unit of measurement of geometric dimensions is millimeters.

Table 1

| Outer

diameter |

Conditional pass |

Weight 1 meter pipes, kg | Pipe wall thickness | ||||||||||

| Reinforced | Of ordinary | Lung | Reinforced | Of ordinary | Lung | ||||||||

| 10,2 | 6 | 0,47 | 0,4 | 0,37 | 2.50 | 2 | 1.8 | ||||||

| 13,5 | 8 | 0,74 | 0,61 | 0,57 | 2,8 | 2,20 | 2 | ||||||

| 17,0 | 10 | 0,98 | 0,8 | 0,74 | 2,8 | 2,20 | 2 | ||||||

| 21,3 | 15 | ˗˗˗˗ | ˗˗˗˗ | 1,1 | ˗˗˗˗ | ˗˗˗˗ | 2,35 | ||||||

| 21,3 | 15 | 1,43 | 1,28 | 1,16 | 3,2 | 2,80 | 2,5 | ||||||

| 26,8 | 20 | ˗˗˗˗ | ˗˗˗˗ | 1,42 | ˗˗˗˗ | ˗˗˗˗ | 2,35 | ||||||

| 26,8 | 20 | 1,86 | 1,66 | 1,5 | 3,2 | 2,80 | 2,5 | ||||||

| 33,5 | 25 | 2,91 | 2,39 | 2,12 | 4 | 3,20 | 2,8 | ||||||

| 42,3 | 32 | 3,78 | 3,09 | 2,73 | 4 | 3,20 | 2,8 | ||||||

| 48,0 | 40 | 4,34 | 3,84 | 3,33 | 4 | 3,50 | 3 | ||||||

| 60,0 | 50 | 6,16 | 4,88 | 4,22 | 4,50 | 3,5 | 3 | ||||||

| 75,5 | 65 | 7,88 | 7,05 | 5,71 | 4,50 | 4 | 3,2 | ||||||

| 88,5 | 80 | 9,32 | 8,34 | 7,34 | 4,50 | 4 | 3,50 | ||||||

| 101,3 | 90 | 10,74 | 9,60 | 8,44 | 4,50 | 4 | 3,50 | ||||||

| 114,0 | 100 | 13,44 | 12,15 | 10,85 | 5 | 4,50 | 4 | ||||||

| 140,0 | 125 | 18,24 | 15,04 | 13,42 | 5,50 | 4,50 | 4 | ||||||

| 165,0 | 150 | 21,63 | 17,81 | 15,88 | 5,50 | 4,50 | 4 | ||||||

When calculating the mass of 1 meter of products, the value of steel density equal to 7.85 g / cm³ was taken as the basis. Non-galvanized pipes are 3% lighter than galvanized water and gas pipes GOST 3262 75.

The maximum mass deviation at the request of the customer shall not exceed:

- for a separate pipe + 10%;

- for the party + 7.5%.

The production of water and gas steel pipes of the aforementioned assortment in accordance with GOST 3262 75 is carried out from steels according to GOST 1050 and GOST 380 without standardizing the chemical composition and mechanical properties. Pipes for parts of gas and water structures are produced in accordance with GOST 1050.

Technical characteristics of water and gas steel pipes GOST 3262 75

The length of the steel water and gas pipes GOST 3262 75 produce in the range of 4m≤ L ≤12m.

If you use this parameter as a criterion, these products are:

- unmeasured length. In the batch of pipes of this assortment, the presence of up to 5 percent of products with a length of 1.5 m ≤ L1 ≤ 4 m is allowed.

- multiple measured or measured length. The longitudinal deviation in accordance with the requirements of GOST 3262 75 for the entire length may exceed the nominal value by 10 centimeters with a cut allowance of up to 5 millimeters.

All tolerances are strictly regulated by GOST and in the presence of deviations exceeding permissible, the product is considered defective.

Important! If the thread is knurled, a reduction in the inner diameter of the steel water-gas pipeline pipe GOST 3262 75 is allowed no more than 10 percent along the length of the thread.

The range of maximum deviations of pipe sizes is indicated in table No. 2.

table 2

| Pipe size | Maximum Deviation Value | |

| Increased manufacturing accuracy | Normal manufacturing accuracy | |

| Nominal diameter |

|

|

| Up to 40 millimeters inclusive | +/- 0.4 mm | plus 0.4 minus 0.5 millimeters |

| Over 40 millimeters | +/- 0,8 % | plus 0.8% minus 1% |

| Wall thickness | — 10% | — 15% |

The indicator "Curvature of the pipe" per 1 meter of length according to GOST 3262 75 does not exceed:

- 2 mm with a conditional pass up to 20 mm;

- 1.5 mm if the conditional pass is more than 20 mm.

One of the most significant technical characteristics of the GOST 3262 75 water and gas pipe is pressure resistance. Depending on the type, a product of this type can withstand:

- reinforced pipe - 3.1 MPa;

- ordinary and light pipe - 2.4 MPa.

Requirements for galvanized steel water and gas pipes pipes GOST 3262 75

The thickness of the zinc coating over the entire surface of the pipes of this assortment should be at least 30 microns. Its absence is allowed on the threads and ends of the products.The galvanized surface should not have inclusions (sintered charge, oxides, hartsink), bubbling and signs of peeling of the coating from the steel base.

Minor influxes of zinc in certain places and roughness, traces of capture of products by lifting equipment and local flux spots are allowed.

Certain sections of the galvanized steel water-gas pipeline pipe GOST 3262 75 can be corrected if they do not have a zinc coating layer of no more than 0.5% of the total surface area. This operation must be carried out in accordance with the requirements of GOST 9.307.

If the conditional passage does not exceed 40 millimeters, the galvanized pipe must pass a bending test conducted around a mandrel with a diameter of 2.5 * Dvn, where Dvn. - the outer diameter of the test product.

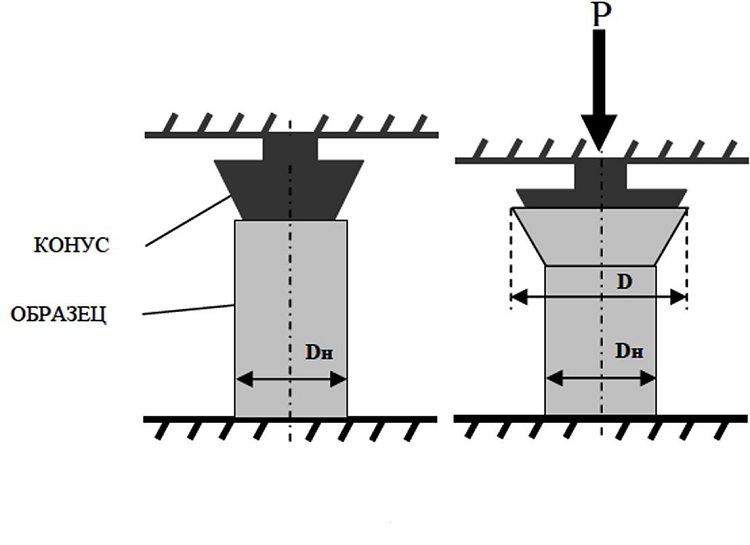

In addition to this method, there is a more rigid technology for checking the technical characteristics of pipes. It is called the “Distribution Test,” expressed as a percentage and determines the ability of the pipe to expand until cracks appear when a cone-shaped body moves in its hole. With a conditional pass of 15 ... 50 millimeters, the value of this indicator should be at least 7 percent. For pipes with a conditional passage of more than 65 millimeters, at least 4 percent.

Helpful information! The above test methods are especially relevant for a galvanized water and gas pipe GOST 3262 75. Indeed, the destruction of the coating layer will deprive the product of many attractive technical characteristics, for which the consumer buys not just steel, but galvanized water and gas pipes.

Galvanized pipes manufactured in accordance with the requirements of GOST 3262-75 are a guarantee of reliability and durability of the pipeline for any purpose.