For decades, cast-iron heating radiators remained an uncontested source of heat in urban apartments. Today, heating equipment is offered in a variety of options - according to the material of manufacture, the method of connection to communications and dimensions. It is in the cast-iron "accordions" that have become classics that the largest number of adherents remains, despite all their disadvantages.

Content

Import and domestic cast iron radiators

In the cold season, comfort in a house or apartment depends entirely on the quality of the heating equipment. Any device for heating a room on a water coolant is gradually clogged, its effectiveness decreases. Over time, any cast-iron batteries have to be replaced or cleaned from clogging of the heating circuit using a special pump. The main sign of clogging and airing is that the heating pipes are much warmer than the radiators themselves.

Of course, communications, including heating, must be properly installed in order to function flawlessly. In many respects, their efficiency depends on the quality of the water circulating inside the heating tanks.

Note! The internal gaps through which the coolant flows are much less in imported models than in the thermal equipment manufactured in our country.

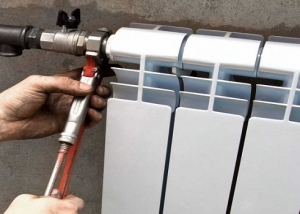

Since the main source of heat in many apartments remains cast-iron heaters, it is recommended to replace them with analogues. Particularly complicates the replacement of "inconsistency" when it comes to self-replacement of old batteries. It is equally important during installation to verify the clearance of pipes and radiators, selecting the appropriate fittings.

For Russian realities, cast iron radiators are recognized as the most suitable. There are not so many varieties:

- classic and designer;

- wall and floor;

- from a large number of sections and a modest format.

Not all products are resistant to water hammer during testing the system for strength, which is carried out at the beginning of the heating season. In new samples, more attention is paid to this. However, in this parameter they are inferior to bimetallic radiators. Thick walls of cast-iron "accordions" guarantee resistance to damage, but increase the weight, respectively, the load on the wall and floor covering. The best technical characteristics are distinguished by imported cast-iron heating radiators.

A method of manufacturing a cast-iron sections

At first glance, the old and new cast-iron batteries are not much different. In fact, the material is the same, only slightly reduced weight and increased heat transfer. Perhaps the residents of Khrushchev and other houses of the old housing stock would willingly replace them with something more modern. But the hosts bribes:

- reliability;

- efficiency;

- affordable cost.

The main disadvantage is that it is impossible to build up several sections if one battery under the window is not enough to fully warm up a large room. This is due to the peculiarities of their production - these are completely cast products that are not subject to melting and cutting at home.Cast-iron sections are reliably connected only by means of a special key.

Cast iron is a brittle metal, the product may crack from a sharp blow with a sharp object. It is unrealistic to process this metal. The casting of identical products, whether it be batteries or pans, made them “identical” from year to year.

Features of cast iron batteries

According to the type of connection, cast-iron heating radiators are classified into:

- 1-channel (vertical models);

- 2-channel (the main variety of cast iron products);

- 3-channel (models with great depths, are rarely found on sale), which have the greatest heat transfer.

Before the perestroika era, several varieties of casting molds were used in the production of cast iron heating equipment. Finished products slightly differed in height, length and depth, the number of inputs for the coolant varied.

Batteries with a center distance of 300 to 900 mm were once produced, but 500 mm became the main standard. At the same time, it became a "classic" for radiators from other types of metal. When replacing old cast-iron radiators, it is important to find analogues on the center distance - this is a guarantee of a reliable connection to communications and the effective functioning of the heating system.

The dual-channel battery has the following characteristics:

- Dimensions (LxWxD, mm) - 93x588x140;

- Power of 1 section - 0.16 kW

- Capacity - 1.4 L

- Section weight - 7.1 kg

- The area of the heating surface is 0.25 m2.

These parameters are valid for the most common domestic model of a cast-iron radiator - MS-140.

In a closed system, sealing is important, in which case it is provided with rubber gaskets. If it is antifreeze, then use paronite gaskets. Not every sealant will be effective in alcohol-containing mixtures used as a coolant.

Old and new cast iron batteries

Since there was no alternative, everyone was satisfied with the old-style cast-iron heating radiators and their characteristics:

- temperature of the circulating stream (water and steam) up to + 110 ° C;

- system pressure up to 15 bar;

- flawless operation for at least 20 years, the possibility of use up to 50 years;

- resistance to chemical and organic admixtures of the coolant;

- low cost.

Cast iron is known for its considerable weight - the heaviest metal used in everyday life. "Accordions" were known because of their heavy weight, which created considerable problems during their transportation and installation. The walls on which such batteries were mounted sometimes could not stand the holders, and the heating elements sagged, disrupting the horizontal. This led to airing of the upper corner and clogging of the lower point.

Many models of the new sample have comfortable legs. They also differ in a more interesting design, often with patterns in the form of metal soldering. In general terms, these blocks for heating a room resemble classic cast-iron radiators, but they are more:

- lungs;

- aesthetic;

- resistant to pollution;

- effective in terms of heat transfer relative to batteries of the Soviet era.

Most of the new cast-iron batteries have positive characteristics:

- The weight is much less, unlike the old ones, with a weight of up to 112 kg.

- High heat transfer coefficient.

- There are practical smooth patterns with a patterned surface (designer), which makes it possible to organically fit into any interior - classic, retro and modern.

- Affordable prices for the entire range of thermal equipment made of heavy metal.

- The equipment operates at different pH levels (acidic or alkaline water reaction).

- Smooth metal models with a painted surface are also available (lend themselves to repainting to their preferred color).

Attention! Usually domestically produced batteries need additional coloring.If you want to change the color of cast-iron heating radiators, pay attention to heat-resistant metal enamels for internal work. This eliminates the evaporation of harmful chemical compounds in residential areas.

Criteria for choosing heating batteries from cast iron

The main indicators for which thermal equipment is selected:

- metal;

- sample aesthetics;

- Battery efficiency (thermal return);

- kind of heating system;

- durability and reliability of the model;

- kind of connection;

- a way to heat the room (not in all cases there is a window sill for batteries).

The quality of cast iron batteries is time-tested, so they remain in demand, despite the considerable weight and specificity. The Russian market is replete with offers not only of domestic design, but also of cast-iron radiators of foreign manufacture. These are well-known brands that produce thermal equipment in such countries:

- Britannia;

- Slovakia;

- Czech Republic;

- Italy;

- Turkey;

- China.

The form of Russian and imported models are practically no different, if not to talk about designer models. A significant difference is the quality of casting and cast iron itself. Because of this, foreign-made radiators have a smoother surface, which favorably affects the reduction in their mass.

Note! Imported batteries have less hydraulic resistance due to a smoother inner surface. But domestic models are more resistant to low-quality coolant.

Products made of heavy metal (from any manufacturer) are characterized by high resistance to metal corrosion. However, gradually all of them become clogged due to the coolant coming from metal pipes.

It is impossible not to recall that cast-iron batteries warm up more slowly than models made of another metal, but they also cool longer. This ability is evaluated differently by potential buyers, but it cannot be attributed to the merits, nicknames or shortcomings of products from this metal. When buying, it is important to pay attention to technical parameters, including heat capacity, in order to correctly calculate the number of "ribs" per room.

Helpful advice: Keep in mind that imported cast-iron heating radiators are slightly more expensive than domestic ones, but they are more “capricious” with respect to the heat carrier that has not undergone thorough filtration and additional chemical cleaning.

Today, on sale you can find not only solid constructions, but also highly artistic sectional samples of gray cast iron. Their casting is carried out according to a special technology in forms that provide excellent characteristics of devices.

The price of domestic and imported cast iron batteries also varies. The comparison can be seen in the table.

Table 1

| The cost of 1 section, rub. | ||||

| MS-140 (Belarus) | Viardus Termo (Czech Republic) | Kiran (Ukraine) | Demrad 350 (Turkey) | Nostalgia (Retro) 500/180 (Turkey) |

| From 340 | From 425 | From 335 | From 400 | From 2120 |

Recommendations for choosing radiators regarding the area of the room

Well-known norms exist:

- heating 1m2 of an apartment in a temperate climate involves 50-100 watts, depending on the floor, the location of the room and its functionality;

- in cold climates, especially on the 1st and last floor - about 200 watts.

There are special computer programs for calculating heating needs. Even if you do not use these schemes, the experience of urban heating plants says that for a room of 15-19 m2 there are enough cast-iron batteries for 10-14 sections (temperate climate).

In a room with an area of up to 15 m2, power is required in the range of 750 - 1500 kW, depending on climatic conditions and the material of the house. However, in some circumstances it is necessary to be guided by a certain margin of power, especially when the water in the pipes is often only slightly warm.

There are also calculation formulas regarding the volume of heated air, which is important in rooms with large ceilings. For panel houses, 40 W is recommended for heating 1m3 (minimum 10 sections per room). In a brick house - 35 watts (approximately 9-10 sections), in a wooden house - 30 watts (8-9 sections).

The power of cast iron products is also calculated taking into account the parameters specified in the technical description of the model. The indicated unit of thermal power of one section is multiplied by the number of square meters of the room - the required number of sections in the model is obtained at the output. However, these are indicative indicators that need to be taken with a margin upwards.