Installation of ventilation is a mandatory procedure dictated by sanitary standards. Installing this system in bathrooms, kitchens and saunas is a must. Pipes for ventilation have many types and differ in their characteristics. To select the right products for your purposes, you should study their properties in more detail.

Ventilation is necessary in almost all rooms and for its installation you can use different types of pipes

Content

Ventilation pipe requirements

Ventilation pipes must meet several important parameters:

- be airtight;

- noise level during air transportation should not exceed sanitary and hygienic standards;

- air must move through them freely and at a certain speed, which was determined in the calculations of the system;

- must comply with the necessary requirements for thermal insulation;

- fit into the design of the room and not take up too much space.

The main elements of ventilation systems

Any system for providing a room with air includes such parts:

Ventilation duct. Their selection, as a rule, depends on the required section and size. As a hood, you can use a profile pipe, because it is easy to install. Rectangular air ducts of the following sizes are popular: 60x120 mm and 60x204 mm.

Connectors There is an equivalent type and transitional. The adapter connector is used if it is necessary to combine two pipes of different sizes.

Turns. This element is used to change the direction of the duct in one of the planes.

The assembly and installation of the ventilation system involves the use of additional parts - angles, turns, mounts and other elements

Tees. They include three outputs for ventilation elements. Used to create branch structures.

Fasteners. They are used during installation of the system for fastening pipes.

Important! Ventilation performance will deteriorate if you install a gas stove or cooker hood for it on the opposite side of the ventilation duct outlet.

Non-return valve. A device that performs a regulatory function. Air, thanks to the non-return valve, moves in the right direction. Typically used when the fan is off in forced systems.

In addition, there are many auxiliary elements that connect pipes with different cross-sectional sizes and shapes. Additional details are selected based on the dimensions of the main components of ventilation. They simplify installation and make it faster.

Pipes for ventilation. Types and characteristics

For exhaust structures, different types of pipes are used: from various plastics, smooth and corrugated from steel or aluminum, galvanized. Corrugated products accumulate dirt due to their ribbed shape and produce more noise during operation. Such pipes need to be cleaned from time to time.

Metal

Such pipes include several types, which are made from different metals and have individual characteristics. These products have several advantages:

- long term of operation;

- strength;

- the surface of most of these pipes is very smooth, which improves the speed of transportation of air masses;

- do not accumulate dirt, soot and dust;

- have excellent resistance to temperature and pressure;

- resistant to aggressive environmental influences.

Galvanized pipes

Installation of ventilation in a private house is carried out in accordance with a given project. The choice of material for the construction is perhaps the determining factor. At the same time, galvanized pipes are quite popular.

Such parts are lightweight, but at the same time retain all the necessary qualities that a metal ventilation pipe has. In addition, they are distinguished by ease of installation (the structure is easy to mount with your own hands) and relative cheapness. The main quality that a galvanized metal part has is a protective layer of zinc, which protects it from the harmful effects of corrosion.

Pipes made of black steel and stainless steel

Ventilation systems made of such materials are often used in enterprises of various kinds. A distinctive feature of such pipes is their operability at high temperature indicators. They are also very strong and mechanical impact they are not afraid. Stainless steel can be used in ducts that transport air masses with an admixture of corrosive chemicals.

It's important to know! Exhaust ventilation pipes can be used to remove products that appear as a result of the gas boiler. But in the cold periods of the year, they can accumulate condensate, which occurs due to temperature differences. To cope with this problem, the outlet of the pipe to the roof is insulated. If this is not done, the condensate, together with harmful chemical compounds formed during the combustion process, will destroy the walls of the product and the adjacent parts of the building.

Plastic pipes

When installing a ventilation structure with your own hands, it is recommended to choose plastic materials, since they are mounted most easily. There are several types of such pipes, but the most popular are polyvinyl chloride (PVC).

Pipes made of polymers can be used in ventilation systems, most often polyvinyl chloride products are used.

Consider the advantages of these products:

- attractive cost;

- ease of installation: practically do not require any special tools and devices. Installation of such pipes is carried out using special elements that are included in the configuration;

- huge range for any conditions and needs. The sizes of such products have a wide range;

- excellent throughput indicators, which are achieved due to the smooth inner walls;

- low noise in the system;

- aesthetic appearance;

- The light weight of these products makes it easy to install and make less complex mounts for them.

- durability in operation.

When selecting such parts, it is necessary to carefully study their characteristics in order to choose what you need. Most often, plastic pipes are installed in private homes. The hood may have a square-shaped outlet, so you should purchase special adapters for reliable connection of the structure.

Corrugated pipes

The use of corrugated parts in ventilation structures has both positive and negative sides. Their undoubted advantage is the ease of installation. During installation work, special clamps are used that tighten and secure the structure with bolts.At one end, corrugated exhaust pipes for ventilation are connected to the hood (fan), and the other end is led out through the roof or wall.

Advantages:

- corrugated parts can be stretched in length;

- compactness (if you fold the corrugation, it takes 3 times less space than a product from another material of the same length);

- has good air resistance;

- provides good performance in the temperature range from −30 to +120 ° C.

Disadvantages:

- some polymers are flammable materials;

- when burning emit harmful chemical compounds;

- accumulate dust and dirt on the walls;

- do not have resistance to mechanical stress.

To choose a pipe that will operate at a certain temperature regime, you should study the table.

Table 1

| View | Temperature (max) | Temperature (min) |

| PVC | +170 | -20 |

| PPU | +130, sometimes up to +150 | — |

| Black steel | Up to +900 | -40 |

| Galvanized | +80, sometimes up to +200 | -40 |

| Aluminum (flexible) | +130 | -40 |

| Stainless steel | From +500 to +700 | -40 |

Is it possible to make ventilation from PVC sewer pipes?

Often when installing ventilation in a private house, plastic sewer pipes are used. This is due to the fact that they are very similar (in their characteristics) to PVC exhaust components. Many people are interested in the possibility of using these pipes in the design of ducts. It is not easy to answer this question, but it is worth considering this option.

For the installation of a household ventilation system that does not require operation under high pressure and temperature, simple sewer pipes can be used

The use of sewer parts for such purposes is more common than it seems at first glance. The main problem when installing them as air ducts is the differences in the sizes of component parts. The diameters and sizes of the two types of pipes often do not match. Therefore, installation of a ventilation structure from sewer products is possible only if it will be carried out from scratch. Combined ventilation is unlikely to be collected due to the difference in dimensions and other indicators.

It should also be noted that sewer pipes are made of less environmentally friendly plastic. This is due to the specifics of the application. With this in mind, their use in the ventilation system can only be carried out if it performs an exhaust function. The use of such parts in the supply structures is strongly discouraged.

In addition, the appearance of the construction of sewer parts is not as presentable as in the case of parts specifically designed for such systems. Specialized elements can be selected for almost any room design.

Based on all of the above items, the feasibility of installing sewer pipes as an air duct is extremely doubtful. But this option still has the right to exist if the ventilation requirements are minimal.

Sandwich pipes

This is an extremely specialized variety that is used in the installation of chimneys and incorporates insulation. Such a product is two pipes arranged in layers. The gap between them is filled with heat-resistant insulating material.

Sandwich pipes are made of stainless steel, which has increased strength and heat resistance. They are made on welded joints, and among themselves, parts can be assembled using locks. A variant is possible in which the pipe is made of other materials (for example, galvanized steel). But such models are less reliable.

“Sandwiches” should be used when installing an external ventilation system, which, according to the technical regulations, must be equipped with insulation. The combination of these parts occurs by the bell method. The price of such pipes is quite high, but it is fully justified by their quality and functionality.

The choice of the necessary design

When purchasing pipes for ventilation, it must be borne in mind that they must have a diameter smaller than the opening of the hood itself. If we neglect this rule, then the noise level during the operation of such a system will be much higher, and the load on the motor will increase and, as a result, the productivity of the system will decrease.

It is worth considering that 1 turn of the exhaust pipe by 90 ° reduces the functional characteristics of the system by 10%. If the bend exceeds the size of the right angle, then this can lead to a complete malfunction in the design due to the fact that the outflow of air will be disturbed.

To cope with the reverse draft, the design provides for the installation of a valve that regulates the air flow and prevents its circulation in the opposite direction. To ensure proper operation, the rotary axis is mounted in a vertical plane. Air is usually vented through a roof or wall. It is allowed to use a combined grill, in which there are openings for conventional ventilation.

According to technical rules, the optimal duct length is 3 m. Each subsequent meter reduces the design's operability by 10-15%.

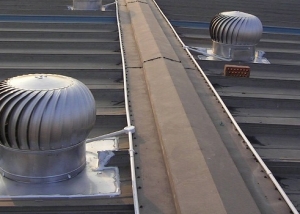

The outlet of the ventilation duct should be located vertically, for this the pipe is often led out through the roof

Features and installation rules of ventilation systems

Installation of natural ventilation. Installation of this type of system should be carried out according to technical standards and it is preceded by all necessary calculations, the choice of materials and their marking. Installing ventilation without a plan for a future design is a risky business.

First, the elements are fastened with special accessories. Then the grilles and deflectors are installed. Special supply valves perform the function of supplying the required volume of air. At the final stages of the assembly, fans are mounted in the ventilation duct grilles. Such devices operate on blowing.

Advice! The best indicator of traction can provide a round pipe. At the same time, air renewal will be faster.

In case of poor ventilation, you can add a check valve to the structure, which will direct more air.

Installation of forced ventilation. This design option is ideal for suburban private houses with a large number of rooms and for rooms in which the humidity coefficient is above normal.

Installation of forced ventilation includes the following steps:

- Initially, work is carried out to install the supply and exhaust unit. This element is located most often in a warm and dry place, isolated from unwanted effects. For this, an attic can be a great fit.

- Further to the block air ducts are attached. The air intake is being installed. It must be positioned so that the gap between it and the pipes is at least 10 meters.

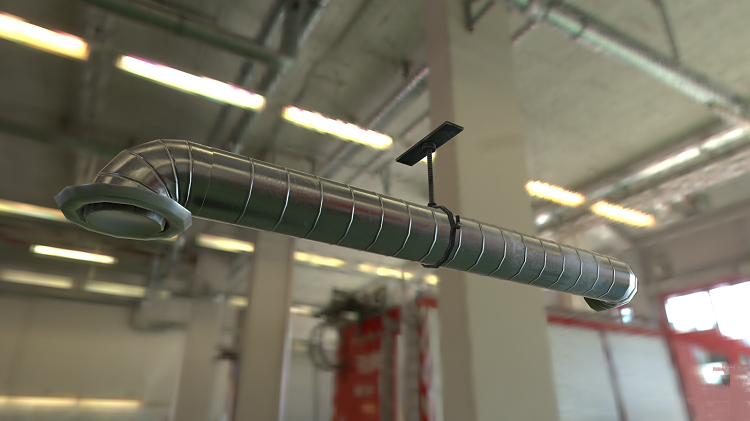

- Then the unit is combined with air ducts (as a rule, corrugated pipes are used for this).

- At the end, the system is insulated, the grilles are mounted on the ducts and various devices are installed that will monitor the operation of the network.

The ventilation system includes many elements, each of which must be selected and installed correctly. Only in this case will the design fulfill its functions and provide comfortable indoor conditions.