This product is one of the types of fittings with which individual elements of the pipeline are fastened together. It is very important that the couplings make the system reliable and tight for a long period of time. Fittings are also required to secure all parts. At the same time, the home master must understand both the characteristics of the elements for connecting the water pipes, and the intricacies of their installation.

Installation of pipelines is not possible without connecting parts - couplings that are available for all types of pipes

Content

Features, application and material of manufacture of couplings

The use of fittings in the form of a coupling allows you to quickly replace various communications when an emergency occurs or during a scheduled repair. The design of these building elements provides the ability to install the water supply in a limited space for a short period of time.

Such a fitting is a short pipe, the ends of which are threaded. Consider the features of these connecting elements on the example of widespread polyvinyl chloride couplings. Their characteristics are as follows:

- not deformed during operation;

- the possibility of mounting the coupling in a wide temperature range: -20 ≤ T ≤ +50;

- fire resistance;

- long service life without replacement and even preventive maintenance.

Couplings are used, also when arranging various PND pipelines. According to technological requirements, such a part should be made of a similar material, in this case, polyethylene. HDPE - raw materials are characterized by the same excellent technical characteristics as polyvinyl chloride. This factor led to a comparable demand for connecting elements made of these materials.

The polyethylene coupling can be mounted in the same temperature range. It is also worth noting the environmental cleanliness of this product and its non-exposure to various aggressive substances.

Important! Design and construction of complex transport pipelines is carried out on the basis of PND couplings.

Most types of such products allow you to not use any special tools when arranging water supply branches. In addition, they are easy to install and cheap. The combination of these properties has provided polyethylene couplings with a high level of popularity in the building materials market. Of their other advantages, experts distinguish:

- high resistance to aggressive environmental influences;

- under mechanical loads exhibit minimal deformation;

- perfectly tolerate both heat and frost;

- reliable and easy fastening;

- the ability to operate without interruption for several decades.

Polypropylene couplings are also on the market. They come in several forms. Below are only the most widely used models.

- With union nut.Installation of a polypropylene coupling of this type is carried out only in front of one device, for example, a water heater.

- The American coupling is detachable (with internal or external thread). It is used where a connector is needed in a cold water supply system. When mounting this type of coupler, pay attention to the gasket. If it is flat and made of rubber, it is not recommended to install an American in these places. Due to the narrowing and expansion of polypropylene at temperature extremes, the plug-in connection may leak.

- The coupling is detachable connecting. Installation of such a part is carried out using fittings having a bell for pairing with the pipe. A polypropylene coupling of this type has proven itself due to the presence of a paronite gasket.

Types of fittings

In addition to manufacturing materials, couplings differ in their technical characteristics, but the main difference is the installation method. According to this indicator, they are:

- compression;

- crimp;

- welded plastic;

- threaded.

Consider each of these species in more detail.

The coupling is compression connecting. Ease of use is the main advantage of such a part. It is fixed by pressing in a special sleeve of the crimping ring. This technical solution eliminates the likelihood of unwinding during vibration of various types, as well as water hammer. Of the advantages we can distinguish:

- universality;

- ease of installation do it yourself. Installation work can be carried out by a person who has only basic plumbing skills;

- the possibility of reuse;

- no need to use a welding machine;

- low cost.

Installation is as follows:

- fastener components - collet, nut, etc. - put on the pipe;

- then the pipe is mounted on the fitting or inserted into the pipe of the connecting component;

- then the collet ring slides over and the nut tightens.

Important! When installing the compression fitting, tighten the nut without excessive force. This requirement is especially relevant with respect to plastic piping. Otherwise, the pipe may just crack.

Crimp coupling. The scope of such a product is metal-plastic water supply systems. It should be noted that the need for a crimp coupling is infrequent. This is due to the fact that the sale of "metal-plastic" is carried out by multimeter bays. When the crimp part is still needed, install it in the following order:

- cut the edges of the tubes at a right angle;

- insert the tubes into the sleeves;

- crimp the connection with a special tool.

Plastic welded socket. The type of plastic makes a difference in the assembly process of the water supply system. Briefly they are formulated as follows:

- PND. Installation of PND water supply, as a rule, is carried out using an electrowelded coupling having electric spirals. Having joined all the details, connect a special apparatus to this type of coupling. After its inclusion, an electric current will begin to flow into the spiral, because of which it will be heated to the melting temperature of polyethylene. As a result, the material of the components is mixed, and after cooling, a very strong connection is formed.

- PVC The installation method of such a pipeline is more similar to gluing, rather than welding. And here the connected surfaces melt, but not because of the high temperature, but under the influence of a special chemical composition - glue. However, this method is called coupling welding.

Installation involves the following sequence of actions:

- cut the connected pipe and insert it into the connecting part;

- on the surface of the pipe, put a mark indicating the depth of entry;

- coat the marked area with a brush with a thin layer of the above glue;

- connect the elements. After doing this, be sure to turn them a quarter turn;

- glue the second pipe a few minutes later in the same way.

Polypropylene. Welding fitting looks like this:

- the connecting part and the pipe are inserted into the preheated nozzles of a special soldering iron;

- after the plastic surfaces soften, remove the parts from the soldering iron and connect to each other;

- allowing the plastic to cool, connect the second pipe to the fitting in the same way.

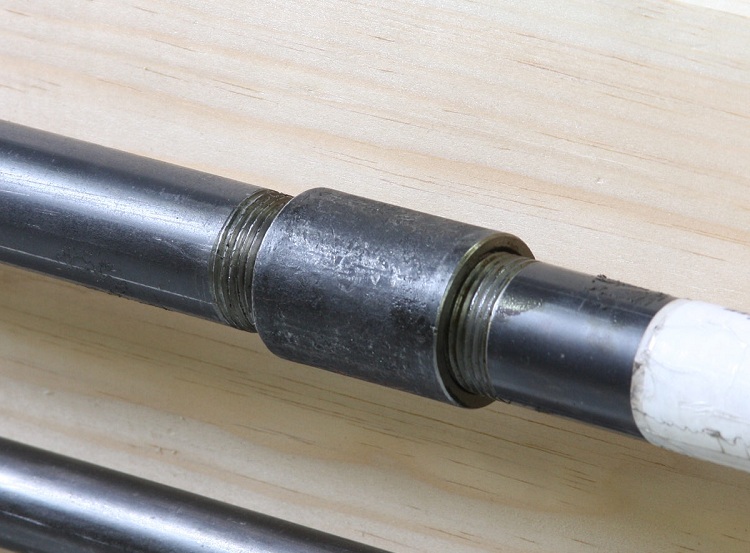

The coupling is threaded. Such fittings are used, as a rule, for steel pipelines. Installation instructions for the threaded coupler are presented below.

- cut the pipes to be joined strictly perpendicular to the longitudinal axis;

- thread them;

- then tighten the compression nuts;

- then, in turn, screw the pipes into the connecting part.

Important! At the final stage, be sure to tighten the compression nuts.

Cast Iron Coupling

When talking about couplings, this product cannot be ignored. Indeed, the elements of sewer pipelines in most Soviet-built houses, of which there are still a great many on the territory of our country, are made of cast iron. Therefore, you should know the installation features of the cast-iron coupling.

For example, to seal the joint, it is necessary to provide access to both the fitting itself and the pipe along the entire circumference. And if the sewer is mounted in the immediate vicinity of the wall, you will have to hollow out a certain section in the wall. Of the other nuances of mounting connectors of this type, it is worth highlighting the following points:

- as a sealant, it is necessary to use organic fiber, impregnated with oil (the so-called heel). However, the result will not be worse if you mint the joint with a graphite gland;

- so that the seal does not fall inward, insert the pipe into the coupling until it stops;

- mint the cable in several revolutions, each of them sealing around the circumference of the pipe;

- in the absence of a special tool, you can do with a wide screwdriver or a thin steel tube, having previously flattened its end;

- after sealing, coat the joint with cement mortar.

Heat Shrink Couplings

These elements are used for insulation of pipelines of water supply systems having a complex profile. The water-shrinkable connecting coupling serves as a double sealing system consisting of an integral fitting having heat-shrink properties and two welded polyethylene plugs. In addition, its design includes two heat-shrink sleeves designed to isolate two adapter sleeves.

Shrink sleeves are designed to connect and isolate the junction of the insulation layer on the pipes

Due to its technical characteristics, such products have found the greatest application in the electrical industry. Of all types of couplings, it most effectively and safely connects various cables. A distinctive feature of the heat-shrinkable sleeve is the possibility of carrying out the procedure for connecting several conductive elements simultaneously, but only if their diameter is almost the same. After the wide production of this type of product was established, modern enterprises began to abandon other products, since their installation does not reduce the cable elasticity index, and the connection is completely and fairly reliably protected from undesirable external influences.

Since we are talking about the electrical industry, we should briefly mention the existence of a coupling for a metal hose, which serves as a means of protecting cables and electrical wiring during installation and operation.

Note! With the help of such a part, it is possible not only to interconnect two segments of the protective structure, but also to ensure their entry into junction boxes.

You should also be aware that the repair of couplings used in electrical engineering is possible. The relevance of its implementation occurs in the case of fixing various breakdowns of insulation of current-carrying wiring. But this is the topic of a separate article.