American Steel - A type of quick-connect coupling invented by resourceful Americans, consisting of two threaded fittings, a hex nut and a gasket. The universality of a reliable and tight connection, which is easy to disassemble and reassemble, has caused its widespread use in water supply and heating systems, pipelines transporting non-aggressive substances.

With the universal connection of an American, you can easily mount different types of pipelines and other systems

Content

Raw materials for manufacturing

The American steel, having been born in such a design, was successfully distributed. Currently, the detachable connection used for the tight connection of the pipes to be connected is made not only of steel, but also of other materials. The American connection, depending on the material of execution, is available to consumers in the following forms:

- cast iron;

- brass. From the point of view of specialists, the most preferable American detachable connection with a union nut is made of brass, due to the durability of the material. In addition, a detachable connection can withstand temperatures up to one thousand two hundred degrees. American brass fitting can be supplied with individual chrome or nickel elements. The high cost of an American brass coupling coupling is completely redeemed by its reliability and aesthetic appeal;

- made of stainless steel. American stainless steel is marked with an indication of the size of the product (in inches), the grade of steel and the nominal pressure (in PSI). American steel combines such advantages as convenience, reliability, familiarity and relatively low cost, but the duration of operation is several times inferior to that made of brass. American steel, unfortunately, is subject to the main scourge of the material from which it is made - corrosion, which is its main drawback;

- combined. Individual parts of the combined American coupling can be made polypropylene. The combined American coupling is capable of operating at temperatures up to -200º C. An American with polypropylene usually finds application for pipes whose working medium is heated to high temperatures and under high pressure.

American women are most often made of steel, but polypropylene and other polymers are also possible.

Coupling design for American pipes

The American steel woman was originally conceived so that there would be no problems with the pipelines if it was necessary to carry out the replacement of a section or carry out repairs. Convenience of the design allows you to quickly disassemble it, repair the damage in the system and restart the pipeline. The connection design is equipped with:

- two threaded fittings;

- quick-detachable hex nut with thread;

- gasket - rubber, paronite or polyurethane.However, cone-shaped models do not contain gaskets.

At its core, an American is a coupling with a collar and with a union nut resting against it. The union nut, rotating, allows the connection of pipes.

Note! The combined coupling is extremely convenient in that it can be easily disassembled at any time and be assembled again.

The combined coupling is decorated with a protective nickel coating, which is very attractive from an aesthetic point of view. Nickel coating protects the product from mechanical damage and corrosion, but requires careful handling.

Combined coupling: types of fasteners and threaded connections

An American plumbing is used to join in pipelines made of different materials. There are Americans for polypropylene pipes and for plastic pipes. A particular type of connection is selected taking into account the specifics of the pipeline system.

There can be several options with which the American pipe and connection fit together, depending on the design features of the product:

- with internal thread;

- with external thread;

- they are provided by the American nut;

- The listed methods are combined in different combinations.

The coupling combined is issued with two types of fastenings:

Conical. Tapered fixtures are particularly reliable. The lack of gaskets in the design does not affect the reliability of the seal. The connection, when a coupling combined with a conical fastening was used, shows excellent stability under temperature fluctuations and even with a deviation of the axes of the joined pipes not exceeding 5º. When installing a thermostat for radiators of the heating system, conical fastening is unconditionally preferred, as it eliminates leakage even at significant temperature drops. An American with a conical fastening is still recommended to tighten the union nut, after wrapping its surface with FUM tape, in order to be sure of the complete tightness of the joint.

Cylindrical (flat). With this classic type, the seal is provided with a Teflon gasket, which is pressed by tightening the nut to the pipe. The popularity of flat seals lies in the fact that the accuracy of the manufacture of components is not critical.

Threaded connections of American women can be:

- straight. Such a combined coupling is used when it is necessary to connect straight sections.

- angular. American corner is truly indispensable when you have to connect perpendicularly converging pipes.

Polypropylene coupling American: varieties

The proliferation of polypropylene, which has proven its worth when laying pipelines and installing plumbing products, has created a need for appropriate fittings with different configurations. Americans for polypropylene pipelines are made in the form of:

- adhesive couplings. Those are especially recommended for installation of a domestic water supply system;

- water outlets;

- angles in 90º and 45º. These are joined pipes with different internal cross-section. Corners of this type are established, as a rule, in areas laid from a water source to housing construction and utility rooms;

- tees and angles for connecting pipes of the same diameter. Their use allows you to give the necessary configuration of the laid pipeline network, avoiding excessive consumption of materials;

- stubs;

- crosses.In conditions when it is necessary to couple several different-level circuits, the use of cross-connections allows to minimize pipe consumption and reduce the cost of laying the system;

- saddles. The implementation of branches from the main thread of the pipeline becomes possible with the use of pipes of different diameters;

- adapters;

- ball valves. Ball valves successfully supersede the usual plumbing fixtures. The reliability of ball valves as stop valves and, most importantly, the possibility of placement in inaccessible places, greatly contribute to their distribution.

A variety of configurations allows you to successfully use an American for metal pipes.

About the undoubted advantages of an American

The main drawback of the American is believed to be its relatively high cost. Perhaps this is the main deterrent to the triumphal spread of this method of connection. Unlike other methods, using an American woman achieves:

- highest quality docking;

- quick installation, requiring only tightening the union nut;

- the ability to quickly disconnect the nozzles at the place of fixation of the pipe, keeping them stationary. If there is a clogging of the water supply pipe, a new branch is cut in, or a damaged area is replaced, then quick disassembly and assembly of the American woman significantly reduces the system downtime;

- unnecessary rotation of the connected pipes;

- perfect alignment of the parts to be joined during installation of the connecting element. With other connection methods, the joint element itself violates the position of the jointed structural parts, which causes a certain violation of its tightness;

- connection of pipes made of various materials.

- repeated procedure for disassembly and assembly;

- ease of installation in inaccessible places. When using overhangs, their dimensions limit the possibility of application, especially in cases where it is difficult to hold an indispensable seal. The installation of an American does not imply such problems;

- refusal to purchase or manufacture an additional sealant, since it is a structural element (with the exception, of course, of versions with conical fastening);

- selection of the necessary form of the connecting element, which has many varieties.

Recommendations for installation using an American

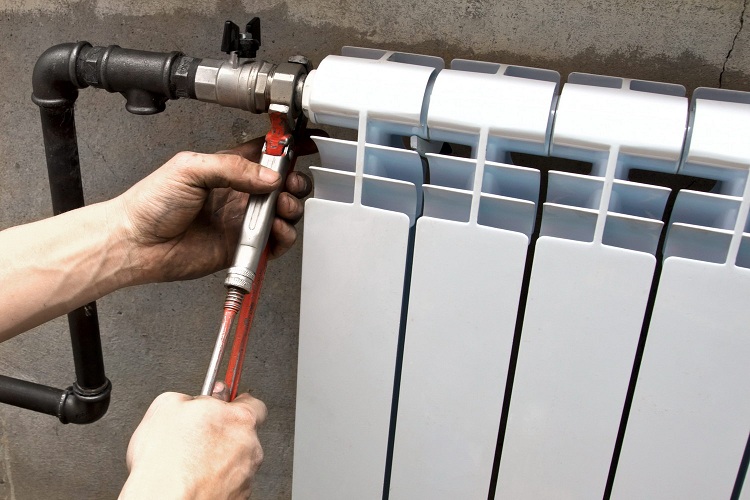

They mount an American, using adjustable wrenches, open-end wrenches and universal wrenches and without resorting to gas, to avoid deformation of the union nut by excessive force.

Good to know! In most cases, it is enough to have keys for 12 and 34 with protrusions. Sometimes, to tighten the American from the inside, the use of a special round key is required.

If there is no thread on the pipe, you have to use a die to cut it, making seven turns. Further installation is carried out in stages:

- The chamfer is removed from the edges of the thread; calibration is necessary for polypropylene products.

- Connecting the pipes, the American is separated, fixing on both pipes. The edges with alcohol or refined gasoline are brought to a clean state, with the removal of moisture, grease stains and grains of sand.

- The fitting is tightened while checking the position of the nozzles, which should be in the same plane. To determine the correct position of the pipe, it is advisable to use some level assistant, which will greatly facilitate and speed up the work. If the position of the nozzles does not match, it is necessary to loosen the fitting and carry out the adjustment.

- Having completed the installation, a leak test is carried out by starting water at the maximum pressure value.After ascertaining the absence of the slightest, even drip leaks, tighten the union nut. Although the American design does not require the use of an additional seal, many plumbers use FUM tape for reliable reliability. Using flax or tow, grease them with special paste-sealant or, at worst, machine oil (distillate).

Carrying out preventive maintenance of the installed system from time to time, simply unscrew the union nut to make sure that it functions normally. Not finding any violations or replacing a damaged system element, the nut is returned to its original position.

Despite the considerable cost, the American is successfully used as a universal tool for laying pipelines and installing plumbing equipment. Work and, most importantly, subsequent maintenance of the installed system, are greatly simplified and made available with a budget and simple skills.