When installing water pipes and sewers, both novice masters and experienced builders prefer lightweight and reliable pipes made of polypropylene (PP). The reason for this phenomenon lies in the practicality of this material and the ease of installation of pipes: even a layman can do such work. For this, crimping with couplings, gluing and welding are used. Last method of joining polypropylene pipes is most popular.

Content

Classification of welding machines and equipment

As you know, the category of welding machines include devices that allow you to create an integral connection. A strong structure is formed by increasing to a melting temperature with subsequent deformation of certain sections (mainly end), supposed to combine products.

The welding equipment for plastic products is divided into two groups:

- manual device. On the slang of experienced installers, its name sounds like this: an iron for welding polypropylene pipes. The reason for this was the similarity of the principles of the household appliance for ironing and devices of this type. For the home master, this is the best option. With the help of such devices, pipes of small diameter (up to 50 millimeters) are welded. However, when using special nozzles, the “gun” (this is another name for manual welding devices) allows you to connect pipes with a large cross section. Nozzles are covered with a Teflon layer, which prevents the plastic from sticking to the surface;

- mechanical welding machine. Using this technique, pipes whose diameter exceeds 40 millimeters are welded. In addition, this unit is used when a lot of effort is required to align the joints. Its design includes a hydraulic unit and an instrument unit. They are mounted on the frame. On the sides are grips made in the form of half rings. Between them are liners, the size of which is selected taking into account the diameter of the connected pipes.

A set of additional accessories depends on the manufacturer and the specific model of the device.

The main equipment options for welding polypropylene pipes are presented below.

- simplest set. It consists of an apparatus and a key for installing nozzles. A great option for the homework of a master who plans to work with pipes of only one ˗ two diameters.

- mid-range kit. This option is most convenient from the point of view of domestic use. In addition to the device itself, the kit includes nozzles for the most common pipe diameters (20 mm, 25 mm, 32 mm and 40 mm). The mobility of the apparatus for welding polypropylene pipes in this configuration is ensured by the fact that they are placed in a suitcase case, which is very convenient for transportation and carrying.

- professional equipment. The acquisition of such a kit for welding polypropylene pipes will be justified if it is supposed to work with polypropylene pipes constantly.It includes everything that a professional needs, and all the equipment (not only nozzles, but also welding tools) is packed in a convenient suitcase.

As a rule, a professional kit includes more accessories than a household one.

Advice! It is possible that you may need more nozzles for welding pipes. In this case, just contact a specialist retailer. There you will certainly find suitable specimens.

Polypropylene pipe welding technology

High-quality combination of products of such products consists of several stages.

Preparation for the operation of welding equipment and pipes is as follows: first, paired special nozzles of the required diameter are installed on the welding machine. From the point of view of sufficiency of heating, their location on the heater is not critical.

As mentioned above, nozzles have a special non-stick Teflon coating, vulnerable to the effects of solid particles. If it is scratched, the required quality of the connection of the PP pipes will not be ensured. Therefore, cleaning nozzles with metal objects is not allowed. This can be done with wooden scrapers or rags in a warmed state.

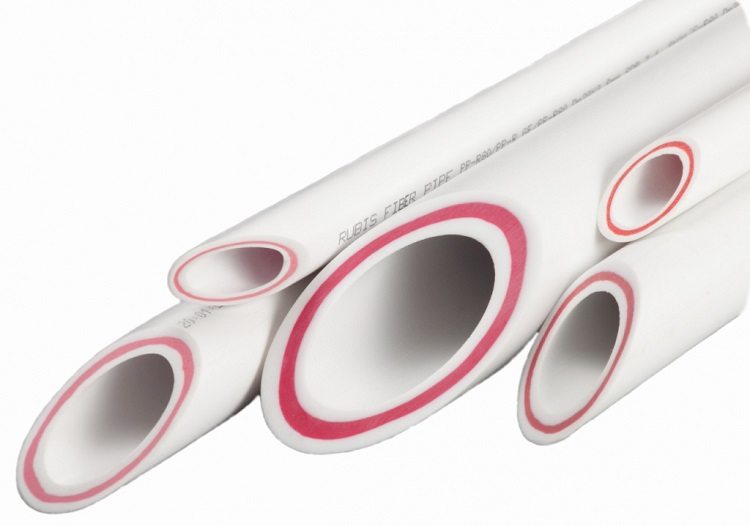

Next, you need to cut the pipes at right angles with special scissors to the right size. The next very important step is cleaning the surfaces to be welded. The substances used for this must be suitable for the type of pipe. When working with products reinforced with aluminum, special cleaning devices must be used to clean the welding zone. If fiberglass acts as the reinforcing layer, it is not necessary to clean the pipe. Particular attention should be paid to a degreasing agent. Only ethyl alcohol, isopropyl alcohol or isobutyl alcohol should be used. It is impossible to degrease polypropylene with vodka, gasoline, white spirit, acetone, since the surface will loosen.

After that, the fitting (sleeve) and pipe are put on the welded nozzles at the same time. The duration of the heating of parts is the value of the derivative of their diameter. Approximate figures are shown in table No. 1.

Table 1

| Welding Belt Width (millimeters) | Pipe diameter (millimeters) | Heating time (seconds) | Cooling Time (minutes) | Connection Time (seconds) |

| 33 | 110 | 50 | 8 | 12 |

| 30 | 90 | 40 | 8 | 11 |

| 28 | 75 | 30 | 8 | 10 |

| 26 | 63 | 24 | 6 | 8 |

| 23 | 50 | 18 | 4 | 6 |

| 20 | 40 | 12 | 4 | 6 |

| 18 | 32 | 8 | 4 | 6 |

| 15 | 25 | 7 | 2 | 4 |

| 14 | 20 | 6 | 2 | 4 |

Important! During the entire connection procedure, the welding machine must remain on. Heating parts should begin at the same time.

The temperature is set on the panel of the device used for welding polypropylene pipes. If a gun is used, its value should be 260 ° C. The time required for the heating element to reach the required temperature is about 5 ˗ 8 minutes.

After the material becomes plastic, the parts are removed from the nozzles and inserted at a predetermined depth into each other. During cooling, the connection must be protected from deformation.

How to choose a pipe mounting fixture

When choosing a device for welding polypropylene pipes, factors such as:

- power. The larger the value of this parameter of the installed heater is, the less time it will take to heat it up to the desired temperature. However, the power and cost of equipment are in direct proportion. The efficiency of the work also depends on the power. Home craftsmen can completely do with a welding fixture, characterized by a small value of this parameter. But here it is necessary to pay attention to the fact that if it is supposed to work with pipes whose diameter exceeds 100 mm, the device must produce power in the range of 1.5 ≤ P ≤ 2.0 watts. In the case when it is planned to connect the elements of the pipeline, traditionally installed in home networks (diameter 16 ≤ D ≤ 63 mm), you can get by with a gun for welding polypropylene pipes with power up to 0.85 kW;

- expediency. The cost and configuration of the product is chosen taking into account the complexity of the proposed work. The existing options were mentioned above;

- pipe diameter. When working with pipelines with a diameter of up to 63 millimeters, it is preferable to use cylindrical and xiphoid manual models. For larger products, mechanical devices will be required;

- temperature condition. Numerous reviews indicate that during operation, increased welding stability is demonstrated by professional welding equipment;

- number of nozzles. Usually install them at once two. This is the minimum necessary set, providing ease of use;

- nozzle coating. The category of the highest quality includes devices with a protective layer of metallized Teflon;

- the presence of the stand and its type. This accessory ensures the stability of the welding machine during operation. The more massive the stand, the less risk that the pipes will stick when removed;

- equipped with protective elements. Before you purchase a suitable unit, in your opinion, pay attention to the handle. If it is not covered with insulating material, it is better to refuse to purchase such equipment for welding polypropylene pipes.

It is worthwhile to carefully study all the models that seem suitable. A serious approach to selection is the key to successful and quality work.

Safety is the main criterion for choosing such a tool, even if you need a household option.

Advice! Since such devices generate heat, they themselves may overheat. To avoid problems associated with this phenomenon during operation, do not be lazy and carefully study the passport of the equipment you like. If protective mechanisms against overheating are not provided in it, it is recommended to stop your choice on another sample.

A brief overview of popular models

The most popular products in this segment of the global market today are products from manufacturers such as Candan and Dytron. Consider their advantages.

Candan The specialization of this Turkish brand is the production of inexpensive, but high-quality professional machines for welding polypropylene pipes. For example, the most striking representative - the CANDAN CM-01 model - is designed so that it is possible to install three sizes of nozzles at once on its mirror. The scope of delivery includes a level with which you can accurately set the device, tape measure and scissors for cutting pipes.

Dytron. This manufacturer from the Czech Republic produces any welding equipment, including one intended for connecting PP pipes. For example, the power of the heating element of the POLYS SP-1a model is 0.65 kW. This device is equipped with three nozzles for working with pipes of diameters of 20 mm, 25 mm and 32 mm, scissors, a clamp, keys and a suitcase.

Today you can choose high-quality equipment for welding PP pipes in any price range. Even the cheapest and simplest “Made in China” welding machines can withstand up to several tens, or even hundreds of on / off switches. If you plan to work in this area constantly, there is no alternative to professional equipment.