A pipe bender for a profile pipe is a very popular equipment on the market. It is used in various fields of industry, housing and communal services and other areas. To save on the purchase of the device, you can do it yourself. However, for this you need to study the device in detail, the principle of its operation and features. In addition, you need to have on hand instructions for its manufacture and carefully comply with all necessary requirements.

Content

Main characteristics

A pipe bender for a profile pipe is a special equipment in the form of a machine designed for bending pipes with rectangular, square and other sections.

Modern equipment of this kind is capable of ensuring the fulfillment of several tasks at once:

- pipe bending at any angle, up to 180 degrees;

- processing pipes of various diameters (it can vary from 5 to 1220 mm);

- deformation of pipes of various manufacturing materials (they can be metal - from aluminum, steel, cast iron; or plastic - from PVC, HDPE, LDPE, etc.)

If plastic pipes can be bent even without the use of a professional industrial pipe bender, then if they are made of metal, this cannot be done without such an apparatus.

There are three solutions to the hardware problem: buy a product, rent it, or make it yourself. If the work is not very much, then the purchase of equipment will be inappropriate. But even if necessary, the acquisition of the device is very expensive. Therefore, many prefer to make pipe bending machines for profile pipes on their own.

Scope of benders

The device in question is widely used in various fields of industry and the national economy. This includes construction, the oil and gas industry, the production of plumbing, the sphere of housing and communal services, and it is also used for domestic needs. This may be the manufacture of garden furniture, awnings, arbors, etc.

However, most often this equipment is used to deform and bend pipes when laying pipelines or erecting buildings (when profile pipes are used as part of reinforcing structures). Tubular products can have a variety of shapes and materials, but in any case, it is necessary to use pipe bending machines to bend them.

Need to know! A factor such as the scope of use is very important for the bending process. After all, tube products of different volume, diameter and material are bent differently, and this requires equipment of different capacities and technical properties. Depending on this, the device can be manual, electric or hydraulic.

Device classification

As mentioned above, pipe bending machines are of several types. They differ in configuration, principle of operation and, as a result, in price categories.

The main are three types of devices.

Hydraulic. Such a pipe bender of a profile pipe must be used if you can not do with your own hands and a simple manual device. Of course, it differs in cost, however, it has more advantages. Among them:

- high deformation rate. Working from the network, such a device for bending profile pipes has more power and performs its tasks much faster than a manual analogue;

- accuracy when setting the bend angle. This is a different view from the previous one. Using the device on a hydraulic drive, you can bend the pipe at the required angle with an accuracy of a degree;

- simplicity in management and service. The simple design of the device provides easy operation and simple repair;

- low operator effort. You do not have to make great physical efforts to give the pipe product the desired shape;

- mobility. Equipment is as easy to move as the previous counterpart;

- universality. If a simple manual control device is not able to work with some types of pipe products, then this type of device is powerful enough to bend steel, even if the pipes are not very small in diameter.

On the electric drive. Such devices have more power, accuracy of adjustment of the angle of bending, however, they are the most expensive.

By the method of bending, devices are also divided into three classes:

- crossbow, with the help of which the bending occurs by using the shape of a certain diameter;

- manual spring, working through powerful springs;

- segmented, representing a segment of wood or other dense material with mandrels mounted on it, around which the pipe bends.

Manual. The cheapest and easiest view. This is a mobile device with small dimensions and weight. In addition, to make such a pipe bender for a profile pipe with your own hands is much easier and cheaper. However, he has enough restrictions. This can not be used if the volume of work is large and regular frequent use of the device is required. In addition, the bending process will take more time and effort, and such equipment can only be used to deform aluminum and plastic pipes, as well as steel pipes with a small cross-sectional diameter.

Manual pipe bender: home-made

Among the owners of garages and private suburban areas, the question often arises, how to make a pipe bender for a profile pipe yourself? This problem is very common, because the finished devices are by no means cheap and buying them, the owner is not always sure of good quality. In this case, making a pipe bender for a profile pipe with your own hands is a real solution.

Despite the simplicity of design, the most primitive pipe benders provide a fairly high-quality processing of pipes

If the scope of work is not too large, then the best option would be a manual pipe bender for a profile pipe.

Important! Remember that a manual adaptation is an unprofessional option, and it is suitable for use from time to time, regular and substantial loads are beyond its power.

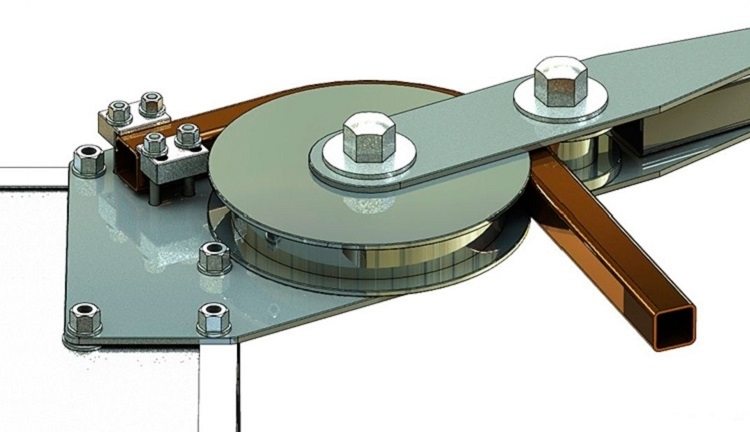

The cheapest and most elementary option is a simple manual pipe bender with your own hands. To make it, you will need only three components: a concrete slab, metal pins and a punch.

The algorithm for installing parts of a manual pipe bender for a profile pipe with your own hands is extremely simple: we divide the concrete base into cells with an area of 4x4 or 5x5 centimeters. At the corners of the formed cells, you need to make holes (drilling them as deep as possible) using a hammer drill, and then install the pins in them.

The resulting equipment for bending a variety of profile pipes works according to a simple principle: the billet of the tubular product is placed between the pins and bent, using physical force, at the right angle.

Of course, you cannot achieve ideal accuracy when using such a simple pipe bender for a self-made profile pipe, but for domestic purposes it is more than enough.

Manual pipe benders of more complex designs

If your requirements for pipe bending equipment are higher, then this simple option is indispensable. In this case, it is recommended to resort to more complex devices.

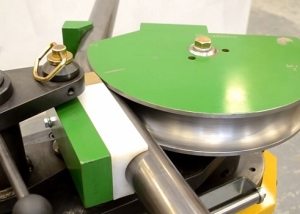

You can assemble a pipe bender for a profile pipe with your own hands, which will work on the basis of a jack. To make it, you will need a hydraulic jack, pins and a solid base.

The bending of the pipe with a pipe bender based on a jack is carried out using a shoe, the size of which must correspond to the diameter of the workpiece

Helpful advice! The jack used as the main element must withstand loads of 5 tons so that the equipment lasts for a long time and without breakdowns.

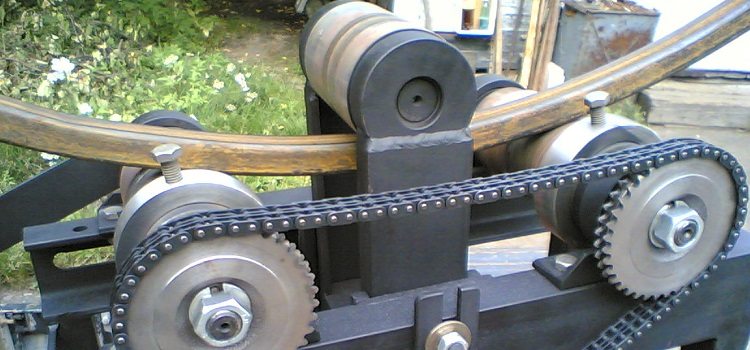

There is a more complex third option - a chain-operated fixture driven by a handle. It is also quite simple to create such a pipe bender with your own hands. It is more convenient to manage and a little more productive.

To make this homemade pipe bender for profile pipes, you need: a metal base of a p-shape, a clamp, three rollers, a chain and a winch.

It is not difficult to assemble this pipe bender with your own hands and it will not take much time. The actions are as follows:

- first, a p-shaped structure is attached to the metal base;

- two rollers are installed on both sides of it, and then the third one (in the shape of an isosceles triangle);

- a chain with a winch is mounted on the rollers.

A welding machine is used to connect the nodes.

How to make a hydraulic pipe bender yourself

The hydraulic apparatus is quite powerful equipment. It can handle steel tubular products of relatively large diameters, compared with the manual counterpart.

However, making a pipe bender for a profile pipe with your own hands in this case will require much more effort and time.

So, to make such a machine, you will need:

- flat base;

- U-shaped metal base;

- feed shaft;

- pulley;

- chain;

- hydraulic stock.

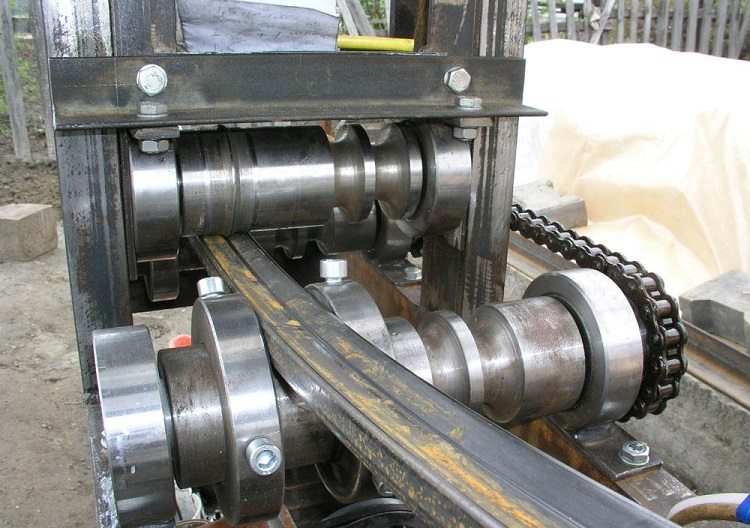

The very design of the do-it-yourself fixture for bending a profile pipe resembles a rolling mill, only more complex and the principle of its operation is slightly different. Instead of a manual drive, a hydraulic rod is used.

How to make a pipe bender for these profile pipes with your own hands?

- first install the shaft on the base. Then a pulley is mounted on the first end of it, and a chain on the second. Now mount the second shaft, connect the chain to the first;

- at the bottom we cut a hole for moving the rod and install a third roller - deforming;

- the shaft of this roller is located in the grooves of the base.

Attention! The basis of a home-made machine for bending profile pipes should be in the form of a trapezoid, if you do not use a u-shaped fork with welded legs (you can use pipe sections or channels as them).

In-house pipe bending machine

A machine for bending different shaped pipes is a rather complicated machine. Making such a machine will require a lot of attention and good skills. It is better, of course, to purchase ready-made goods, however, if you are confident in your abilities, you can make such a pipe bender with your own hands.

First you need to get everything you need, namely:

- concrete slab;

- castors;

- winch;

- engine;

- jack;

- metal jumper;

- gear motor.

First, a base is prepared, made of metal parts using a welding machine. After it 4 support elements are installed on it. Now you can make holes to adjust the bend radius.

Then the jack is mounted. For this, bolts and plates are used.

Now we install the rest of the details: the winch and rollers (as in the simpler design discussed above), the engine and gearbox, as well as the jumper.

After this, the last stage remained - the manufacture of the so-called fungus. To do this, you can purchase a pipe bent 90 degrees in any hardware store. Such a part is installed on top of the apparatus body.

If necessary, a machine for bending profile (square, rectangular) pipes can be made independently. The complexity of the design and the cost of components for it will depend on the purpose of the device and its frequency of use. It is also important how correctly the assembly work will be carried out. The reliability and performance of the device as a whole depends on the accuracy of the actions.