The ductility of metal-plastic pipes makes it possible to use various methods of bending them. Thin-walled steel pipes are often required to bend. In this case, the incorrect conduct of this operation can deform or destroy the design of the product. It is possible to use a pipe bender for pipes or do it yourself. The pipe bender is used for a wide range of works, for example, when installation of a water supply pipeline, air conditioning, heating and ventilation systems.

Content

Features of pipe bending

A technological process in which under the influence of external loads the inclination of the axis of the pipe changes is called bending. In this case, elastic-plastic and elastic deformations occur in the pipe walls. A compressive stress appears on the inner wall, and tensile stress on the outer wall with a maximum value in the central part.

The material, diameter and wall thickness of the pipes determine the method of their bending and its minimum radius. Values for steel pipes are given in the table.

Table 1

| Pipe diameter mm | Minimum bending radius | |

| wall thickness up to 2 mm | wall thickness above 2 mm | |

| 5-20 | 4 pipe diameters | 3 pipe diameters |

| 20-35 | 5 pipe diameters | 3 pipe diameters |

| 35-60 | — | 4 pipe diameters |

| 60-140 | — | 5 pipe diameters |

If the bend is made with a smaller radius, then its quality will deteriorate and the product will be deformed.

Bending leads to a change in the shape of the cross section of the product. Instead of a round pipe takes an oval shape. When bending thin-walled pipes on the concave side, folds can occur that adversely affect the operation of the pipeline: the flow area decreases, the anticorrosion properties deteriorate, and the hydraulic resistance increases.

Classification of devices for bending

The use of a pipe bender for metal-plastic pipes and thin-walled steel is advisable if necessary, bending them at different angles. Distinguish these types of devices:

- hand held;

- hydraulic;

- electromechanical.

Do-it-yourself manual pipe benders for metal-plastic pipes allow you to bend thin-walled products with a diameter of up to 5 cm at an angle of up to 180 °.

Important! Schemes for more complex hand tools can be equipped with a power blower, handles, bypass valves, which ensures more efficient use of the pipe bender.

The hydraulic machine is designed to work with pipes up to 12 cm in diameter and can be manual or stationary. Such a tool has a refractory body that can withstand large mechanical loads, and a hydraulic pump. Electromechanical pipe bender is a multifunctional device with program control.

By the method of bending, the devices are divided into:

- spring;

- segmented

- crossbow.

With the help of a spring bender, copper, aluminum and metal-plastic pipes can be bent without deformation.Its advantages are durability, simplicity of design, maintaining good rigidity and the necessary shape, regardless of the number of bends. Segment pipe benders perform bending around themselves. Using a crossbow device, you can bend a pipe of a certain diameter at an angle of up to 90 °. It differs in small dimensions and low price.

Benefits of Using a Bender

The use of a pipe bender to give the metal-plastic or thin-walled steel pipe the required shape is the most optimal and effective option. This method allows you to qualitatively bend the product without damaging the structure. Advantages of using a pipe bender:

- the least risk of warping the pipe;

- ease of use;

- the possibility of using pipes of any diameter;

- safety when performing a bend.

In addition, the working cylinder of the device is filled with oil and is ready for operation. The design of the pipe bender is made of metal, which ensures its impact resistance. During work, there is no need to heat the pipe. Using a hydraulic pipe bender, it is possible to reduce the number of welding and threaded joints, which improves the quality of installation.

The pipe bender for plastic pipes allows you to rationally use the space of the room and optimize the placement of communications. Bending of pipes is obtained without flattening and creases, which positively affects their operational properties.

Characteristics of a spring bender

Structurally, a spring bender is a spring of steel of a certain diameter and length. At one end of the tool there is an extension that is designed for the convenience of the user. Such a bender allows you to bend the pipes with your own hands in any direction at all possible angles.

Before starting work, the required spring diameter is selected and it is inserted into the metal-plastic pipe. Some models involve the introduction of a pipe inside a pipe bender. The inner or outer diameter of the tool must match the diameter of the particular product.

Note! If the pipe bender is of the internal type, then the internal diameter of the metal-plastic products is taken into account, if the external is the external.

The material and shape of the spring prevents folding, kink or cracking of the pipe. Its deformation during use does not occur. After reaching the desired bending angle of the pipe, the spring is removed and ready for further use.

Before purchasing a spring bender, you must make sure that its characteristics correspond to the parameters of the pipes. Particular attention should be paid to such parameters:

- pipe diameter;

- spring length;

- device weight.

The pipe diameter is usually indicated in millimeters or inches.

The length of the pipe, which can be bent, depends on the length of the spring. In some cases, the spring can be moved relative to the pipe and thus bend its sections. The weight of the spring bender ranges from 200 to 600 grams.

The main parameters of the hydraulic machine

The design feature of the hydraulic pipe bender is the presence of an integrated pump. Such a system does not require additional maintenance, but allows you to minimize the applied efforts for bending pipes. The heavy-duty metal housing protects the device from mechanical stress and shock. Thanks to the lever transmission, the operator has the ability to constantly monitor the bending process and achieve the desired angle.

Hydraulic pipe benders come with a closed and open frame, which affects the speed of replacement of workpieces. The modularity of the system allows you to choose electric or manual hydraulic pumps.

Manual (autonomous) drive can be flexible pipes without a power source. Electro-hydraulic pipe benders are much heavier than manual benders, but they allow bending of large-diameter products.

For bending thin-walled steel pipes with a diameter of up to 4 inches, it is better to use a pipe bender having an electric motor. The most popular brands are Rothenberger, KERN, REMS, RIDGID.

Winding and crossbow devices for bending

Based on the design, devices for bending pipes are:

- winding;

- running in

- on the supports.

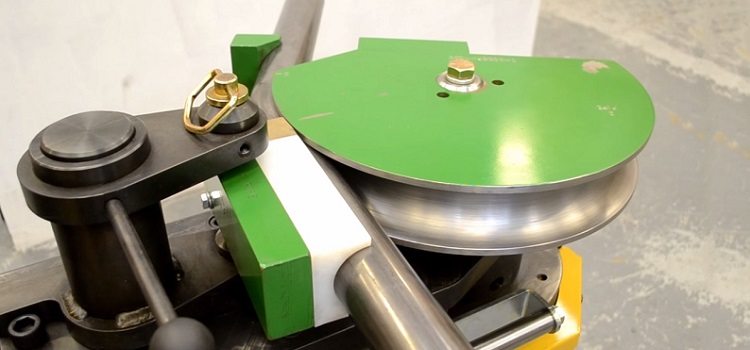

When using the winding method, the pipe is pressed against the bending roller by means of clamps. It rotates and thereby winds the pipe on itself until the desired angle is reached. The bending radius will be equal to the radius of the roller.

During such bending of a thin-walled pipe with their own hands, crushing of its walls can occur. To avoid this, when performing the bending operation, a mandrel is placed inside the pipe - a special rod of the required diameter with a rounded end. It reaches the bending point and prevents the pipe from collapsing. Dorn can be flexible, consisting of connected sections.

Important! For the winding method, the minimum bending radius is one and a half pipe diameters.

In the rolling method, 3 rollers are used, which rotate in the same plane. Two of them are supporting, the third is a clamping one, which hangs on the pipe in the center of the span. Bending rolls are used to bend large radius pipes.

The principle of the crossbow benders is similar to the previous one, but the pipe does not roll, but rests on two supports. A roller is pressed between them, squeezing the pipe to the desired radius.

Pipe bending

If a manual pipe bender for steel pipes works by the break-in method, then the pipe is placed between the rollers. One of them is motionless, the other is break-in. The pipe is fixedly mounted on a bending template. In an arc around it, making a reciprocating motion, the roller moves and presses the pipe with some force, gradually forming the necessary bending radius. Such benders do not require the use of mandrels, so the minimum bending radius is 3-4 pipe diameters.

In the bending template, the size of the stream should match the outer diameter of the pipe. The quality of the bend is affected by the distance between the pipe and the breaker roller. At a small distance, great efforts are required to create a bending moment, which leads to severe ovalization of the pipe. A very large gap affects the cross section, which becomes unequal on a bent pipe section.

Recommended clearance values depending on the diameter are: with a pipe diameter of 5 to 10 cm - from 6.35 to 12.7 mm; with a diameter of less than 5 cm - 6.35 mm.

DIY pipe bender at home

The easiest way to bend the pipe with your own hands is to use a template that can be cut from wooden boards. They are connected and attached to the base. Such a pipe bender is equipped with a stop for fixing the pipe.

With your own hands you can create a rolling pipe bender. The only difficulty is finding or making templates and clips. To obtain the necessary shape of the flexible pipe, you can use wooden parts. When performing more complex work with pipes of significant stiffness, wooden elements (or the entire structure) should be replaced with metal ones. To obtain the correct circumference, the pipe must be rolled at a constant speed.

Important! The larger the distance between the rollers, the less force is required to bend the pipe, but the larger is the minimum bend radius and the longer the length of the pipe end that cannot be bent.

The disadvantages of DIY pipe benders are the inability to accurately control the radius and other parameters of pipe bending, working only with thin-walled or soft metal pipes.

Thus, pipe benders allow quality and without damage to bend pipes. If this operation is disposable, it is better to consult a specialist. For use at home, you can make a pipe bender for your own hands.