When using steel pipes of various diameters, the need often arises for their cutting. To solve such problems, a manual or electric version of the pipe cutter is used. Such a tool is a special modern device that allows you to get pipe segments so that it is convenient to work with them (weld, thread, etc.).

Content

- 1 General provisions for cutting steel pipes

- 2 Features of choosing a pipe cutter

- 3 Classification of mechanisms by type of construction

- 4 Electric and manual pipe cutter

- 5 Hydraulic and pneumatic tools

- 6 Features of manual pipe cutters for steel pipes

- 7 Work with electric pipe cutters

- 8 Instrument Use Rules

- 9 How to cut different types of pipes

- 10 Popular pipe cutter manufacturers

General provisions for cutting steel pipes

Depending on the task, the contractor can use one of the methods for cutting steel pipe products:

- using a pipe-cutting tool;

- electromechanical circular saw;

- gas pipe cutting;

- plasma cutting;

- on special pipe cutting machines;

- on special abrasive cutting machines;

- on a band saw;

- cutting machine.

Obtaining segments of steel pipes using hacksaws is acceptable only at home or in workshops, since the process is labor intensive and low precision. The use of electric tools allows you to increase the speed and quality of work.

Special machines for gas and plasma cutting are able to provide high accuracy and good quality edges during the processing of non-standard and standard pipes. Such mobile and universal devices with mechanical or manual drive can perform cutting at an angle or with different thicknesses of cut.

The most accurate is laser cutting, however, its use is not always advisable due to the significant cost of the process. Machine-tool equipment for cutting steel pipes is used in mass and mass production because it allows you to get workpieces identical in size. This method is not limited in cross-section and material of manufacturing products, and can also be used for batch cutting of pipes with small diameters.

Features of choosing a pipe cutter

When choosing a suitable tool, it is important to consider some technical characteristics, including:

- maximum and minimum pipe section;

- material from which the product is made.

The thickness of the processed pipe, with which the pipe cutter is able to work, allows us to distinguish the following categories of the latter:

- for heavy loads;

- for ceramics and asbestos cement;

- for thin-walled pipes.

A manual pipe cutter for steel pipes is able to cope with all other types of products whose manufacturing material is less durable.

Note! The mechanism for heavy loads can even bite a product with a diameter of 12 inches, made of steel or cast iron.

Its design includes reliable clamps for fixing the treated surface. Apparatus for thin-walled pipes, as a rule, manual. There are models for brass, copper, stainless steel, metal plastic.

Classification of mechanisms by type of construction

There are some types of tools that differ from each other in their design features:

- incisor;

- roller;

- chain;

- rotary or rotary telescopic;

- with ratchet gear.

The cutting tool is most often used for cutting plastic pipes. It is a kind of clip made of steel. Special disks are mounted in it, distinguished by special strength, which provide a cut of the material. The position of the discs is adjustable. The maximum cross-section of pipes with which you can work is 100 mm.

The roller mechanism is designed for steel products. Such a pipe cutter consists of one to three rollers that are responsible for cutting, and guide rollers. The diameter of the pipes depends on the number of rollers: a three-roller device can cope with a product with a cross section of up to 100 mm, a single-roller device can not exceed 50 mm. The pipe cutter does not always allow you to get an absolutely smooth cut.

Chain-type devices allow you to work with materials that are fragile: concrete, ceramics, cast iron. In such pipe cutters there are pivoting levers, a tensioning mechanism, chains with rollers. The last type of tool can cut single-layer thin pipes with a cross section of up to 3 cm.

A rotary pipe cutter is the most expensive apparatus that allows you to work at the bottom of trenches, pits, under water. It has the same interchangeable rollers, which are fixed around the product, cutting it, as well as a removable handle, which sets it in motion. Such a pipe cutter copes with structures with a wall thickness of up to 19 mm.

Electric and manual pipe cutter

The pipe cutter for steel pipes is manual and electric, and then pneumatic and hydraulic. The first type of tool is lightweight and easy to use. To perform the cut, it is enough to fix the device in the required place and perform several revolutions.

The second variant of the mechanisms is advisable to use when carrying out extensive work or processing large diameter products. Due to the use of better and wear-resistant materials for its creation, electric pipe cutters for steel pipes are suitable for more intensive use.

Note! Roller hand tools are excellent for performing work at heights or in cramped conditions, since they allow you to cut a certain section of the steel pipe without wrapping it whole.

The electric tool is equipped with a motor by which the mechanism is driven. Such devices are more expensive than manual counterparts, but they function faster and easier.

Among the main advantages of pipe cutters for working with steel pipes are: wear resistance, a cutting part made of alloy steel, material strength, high cutting speed when processing products of any diameter, excellent balance, a smooth and accurate cut without unnecessary auxiliary manipulations, and the ability to replace rollers if necessary, in the processing of a different type of pipe.

Hydraulic and pneumatic tools

Hydraulic pipe cutters are equipped with a piston, rod and hydraulic pump. Their operating principle is based on liquid pressure. During operation, the pump presses on the piston, actuating the pipe cutter. When the water pressure weakens, the incisors return to their original state. Such tools do not require an electrical connection, but their power is significantly lower than that of electrical counterparts.

Pneumatic devices are used to work with products, the cross section of which reaches 13 dm. Such devices are equipped with cutters of various types, which allows them to be used for both plastic and metal structures.

Pneumatic pipe cutters have significant dimensions, and their weight can reach 60 kg. Complete with them, as a rule, they sell special carts on which they are transported.

Features of manual pipe cutters for steel pipes

A feature of manual type pipe cutters is their work due to the application of human muscular strength. At the same time, it is possible to directly control the entire process. The electric mechanism has a lot of nodes that can fail, require constant cleaning and monitoring the technical condition.

Note! When working with its use, the product may be damaged due to a power failure or short-term malfunctions of the moving belt (or motor), etc.

On the other hand, cutting large-diameter steel pipes for a manual type pipe cutter is not always possible, although the device uses a system of levers to increase the applied force artificially.

At the household level, products of a small section are usually used, so a manual device is more convenient than an electric one. Such mechanisms are characterized by good ergonomics and convenience. In addition, the work can be carried out at a pace that is acceptable to a person, and the cut of the pipe will not have any nicks and need to be cleaned before the subsequent use of the pipe.

Work with electric pipe cutters

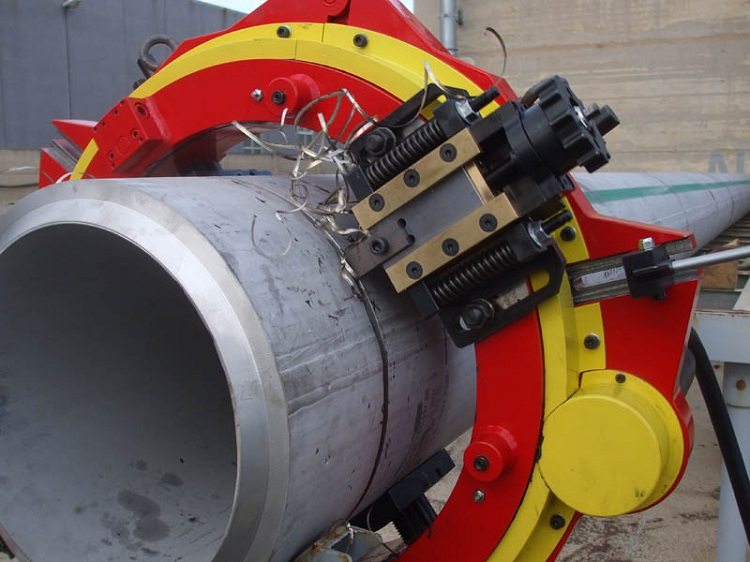

Distinguish between detachable and one-piece electric pipe cutters. The first type of tool is best for professional use. It has a housing that is divided into two parts. This design allows you to install the pipe cutter on a previously mounted pipeline if it needs to be repaired.

At least 2 cutters are used as cutting elements. In some cases, one of them is used for chamfering, and the other is used directly for cutting. The electric pipe cutter is fastened by means of cams. Their number can be from 4 to 8, depending on size. A servo drive is usually included in the tool kit, which controls the cutting progress and protects the device from overloads. To work with thick pipes, special types of cutters are used.

At the initial stage 2, the detachable halves of the device are mounted on the pipeline and aligned vertically relative to it. For large diameters, additional patch cams are used for fastening. Cutters set 2 millimeters from the edge. You can verify that the installation is correct by fully turning the toolholders. Next, the servo is mounted.

During operation, the cutters are automatically fed, and the power tool allows you to perform mechanical cutting of pipes, removing the inner and outer chamfers, trimming and chamfering with blunting.

Instrument Use Rules

Proper operation of the pipe cutter is a guarantee of its durability and quality of work. When using this tool, it is important to control the clamping force of the steel pipe. Excessive force can lead to a mismatch between the beginning and end of the cut line (i.e., the appearance of a helix) and damage to the pipe cutter itself.

Note! With a very fast rotation of the mechanism, the walls of the pipe collapse - the formation of burrs - excess cut metal.

The main rules for the care of the pipe cutter include:

- obligatory cleaning of the surface of the cutting roller, feed screw and guide rollers with a special tool after work;

- good lubrication of guide rollers and feed screw;

- visual inspection of the instrument for dents, chips and other external damage;

- obligatory check of sharpness of the cutting roller and its replacement in case of blunting;

- Store the pipe cutter with a warm, dry place.

By observing the above rules, you can ensure the clarity and durability of the mechanism.

How to cut different types of pipes

A manual roller pipe cutter is most often used for cutting steel pipes. The simplest work procedure has the following sequence:

- marking an object along its entire length;

- wetting the metal with oil or plain water;

- installation of the pipe in the clamp, which is located on the pipe cutter;

- opening the clamping unit and inserting an object;

- applying a cutting roller to a pre-drawn line;

- good tightening of the locking mechanism.

Next, the mechanism is rotated with its gradual tightening, increasing the tension in the block. If the pipe has a large diameter, then the work will be longer, since the rollers in the tool must be moved around the entire circumference of the product, while their deep incision into the material will be traced.

For metal-plastic or polypropylene pipes, a manual guillotine-type pipe cutter is suitable. For the cut you need:

- marking at the place of the desired separation;

- the extension of the handles of the instrument, the girth of the pipe and their closure;

- pressing the handle so that the guillotine knife passes through the diameter of the product.

When closing the handles, the blade should touch the mark, and at the end of the process, alignment of the profile with the internal diameter will be required, since it wrinkles slightly during cutting.

Popular pipe cutter manufacturers

Products for cutting steel pipes on the modern market are represented by such companies: Virax (France), Kraftool (Germany), Rothenberger, Super-ego and others.

The French manufacturer Virax produces professional equipment for processing pipes made of steel and other materials. Among such tools, gas and plumbing wrenches, threading machines, hydraulic pipe benders, roller pipe cutters, a vice and pipe clamps, straight pulleys, chamfers are distinguished.

In order for the equipment to be reliable and serve for a long time, one should give preference to a well-known company.

The German company Kraftool has gained wide popularity due to its versatility, high quality and product reliability.

Note! Tools are created specifically for professional use, but domestic consumers can also use them.

Another German concern - Rothenberger - has been operating on the market for over 60 years. The main products of this manufacturer are:

- mounting tool;

- manual crimping and pipe freezing products;

- tools and materials for working with copper, steel and plastic pipes;

- equipment for cleaning pipelines;

- diamond drilling rigs.

The Taiwanese company Jonnesway provides a lifetime warranty for pipe cutters, subject to all operating rules.

Without a pipe cutter, high-quality repair of highways and cutting of steel pipes is almost impossible. Thanks to this tool, you can ensure good cleanliness, accuracy and straightness of the cut.