When performing repair work, it is often necessary to change the configuration of the pipes in order to give them the desired shape. This result can only be obtained using a special tool. But to acquire a device for the sake of only a few operations is impractical. Nevertheless, every master should take care of the presence of a pipe bender in the arsenal, since bending a pipe product may be required at the most unexpected time.

Content

General information

This tool has several features in its design. It is thanks to them that it is possible to bend pipes, including metal ones, without any problems, giving those a given angular radius with the expenditure of minimal physical effort. Such equipment is divided into several types:

- manual pipe benders;

- hydraulic pipe benders. Models of this type can also be attributed to the category of hand tools;

- mandrel;

- spring.

But there are devices of another design:

- electromechanical;

- segmented

- crossbow.

All the above tools are characterized by positive and negative qualities, but each of them allows you to bend a metal tubular product with a circular cross section without significant physical effort and in a short time.

The easiest option is to go to the nearest specialized store, in the assortment of which there are devices of this type. But a person who has experience in making the most diverse devices with his own hands will be able to create a manual pipe bender at home.

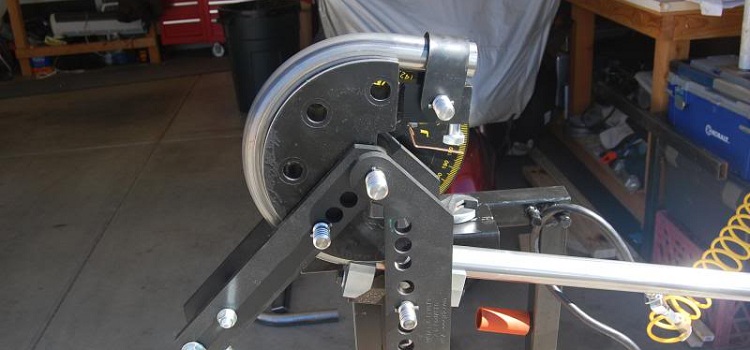

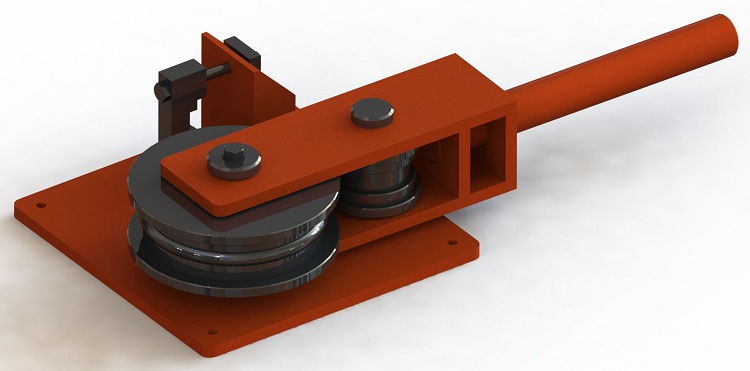

You can purchase a factory-made tool, but it is quite possible to assemble it yourself from improvised materials

Device. Operating principle

The type of pipe bender largely determines its design. However, each device includes a standard set of elements. The key working component is the pressure nozzle (pressure), which is under pressure. As a result of its impact, the angle of bending of the pipe changes.

The manual pipe bender is characterized by a design including a spring with a clamp, while electrical devices are equipped with electric motors. The pressure is driven by precisely these elements.

Regardless of the type of pipe bender, the unit includes several shafts (templates / rollers). They perform the function of stabilization and regulation of the bending radius of the workpiece. The impact on the pipe involves its preliminary fixation between the pressure plate and the shafts. The realized amount of bending is regulated by the position of the shafts. For example, if you want to form an acute angle, the shafts are placed close to the pressure and one to the other.

Good to know! In a homemade pipe bender, most often this is not possible due to the simplicity of the design.

The type of equipment also determines the way it affects the pipe. Methods are as follows:

- rolling (rolling). 3 movable shafts are used here. Bending radius - the value of the derivative of the location of the support rollers with respect to the central shaft, which also exerts pressure on the pipe;

- impact on the tube stock with a rod (crossbow method). In this case, two stationary rollers serve as a support, and the template between the rod bends the pipe between them;

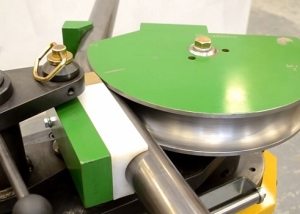

- winding. When winding the pipe with a special clamp is pressed against a rotating roller. In this case, the roller wraps the workpiece, stretching it between itself and the stop;

- running in. In this method, the pipe bender clamps the ends of the pipe, the template remains stationary, while the pinch roller, moving, bends the workpiece.

It should be noted the versatility of this tool: it can be used to bend various types of tubular products:

- plumbing;

- gas;

- boiler rooms, etc.

The pipes themselves can be made of:

- metal plastic;

- aluminum;

- copper;

- steel.

The only restriction concerns the diameter of the pipes: the value of this parameter should not exceed two inches.

The nuances of working with a manual pipe bender

Consider the features of the use of this equipment on the example of its most popular types.

Crossbow pipe bender. For home craftsmen, faced with the need to bend thin-walled tubular products made of brass, aluminum and copper, or thin pipes made of metal-plastic, this tool is the best choice. It is great for working with pipes whose diameter varies in the range of a millimeter. At the same time, anyone with only basic technical skills can do the job.

The simplicity of the design of the crossbow pipe bender is realized by converting the effort on the handle by pressing the lever. Thus, the compression force of the tool handle directly determines the bending angle of the final product. As practice shows, in order to form a smooth, without deformation, arc with a bend angle of 90 degrees from the pipe, the efforts of one male hand are enough. But there is one requirement: to eliminate crushing or tearing of the walls, it is necessary to choose the right punch. It should correspond to the diameter of the bent workpiece.

Manual hydraulic pipe bender. This type of equipment comes to the rescue when the capabilities of a crossbow bender and hands alone are not enough. The device is ideal for metal pipes with a diameter of 12 ≤ D ≤ 100 millimeters. Before working with a manual hydraulic pipe bender, make sure that the cylinder rod is correctly positioned. In this case, he must be in a non-working position. That is, in order to prepare the operation unit, the contractor will need to raise the overflow valve screw by half a turn.

Note! Before work, it is necessary to place the hydraulic cylinder on a horizontal level surface, and fix the lower crosshead.

To prepare the hydraulic manual tube bending machine for work, we take a bending shoe. Its marking should correspond to the diameter of the workpiece. Next, we attach this accessory to the hydraulic cylinder rod so that the punch takes a horizontal position on the pipe bender. Having installed the bending segment, we insert the stops in the holes closest to the hydraulic cylinder. Now the manual pipe bender is ready to work completely.

How to prepare pipes

To get a high-quality result on a hydraulic pipe bender, you need a little math. It must be taken into account that such a sufficiently powerful device can damage pipes. This concerns, first of all, products characterized by the following ratio:

Sst /Dvn < 0,06 ,

where: S - wall thickness; Dvn. - outer diameter.

For example, for a pipe of 20 millimeters with a wall thickness of 2 millimeters, this figure is 0.1, which is quite acceptable. But a thin-walled (1 mm) pipe of the same diameter does not fit this condition, since the ratio is 0.05.If you use a manual hydraulic pipe bender, without fractures and jams of the walls of such a tubular product will not do. Avoiding these troubles will allow stuffing to the brim with dry and clean sand with sealing pipes on both sides.

And one moment. Suppose you do not have a segment of the right size for the billet proposed for bending, but there are large diameters for them. The installation of an additional soft copper or aluminum insert between the segment and the pipe will help to solve this problem. Its thickness is calculated by the following formula:

Sstand = (Dpr.s.— Dt)/2 ,

where: - insert thickness; Dpr.s is the diameter of the groove of the segment; Dt. - pipe diameter.

Consider the following example. There is a segment designed for pipes with a cross section of 26 mm, and the workpiece installed in a pipe bending machine has a diameter of 18 mm. Substituting these data into the formula, we get that the plate thickness should be (26-18) / 2 millimeters.

For manual hydraulic pipe benders, there are also restrictions on the minimum allowable bending radius - 4 pipe diameters. That is, a pipe product with a diameter of 20 millimeters can be bent to a minimum radius of 80 millimeters.

Making a pipe bender

It’s easy to create a simple fixture for bending pipes with your own hands. The only thing you need is locksmith skills and a specific tool:

- Bulgarian;

- welding machine;

- pencil and tape measure.

It’s easy to assemble a primitive pipe bender, the main thing is to buy or make templates of the right size

From the materials you need several metal sheets with a thickness of 10 and 3 millimeters, and, in addition, a certain number of steel bars.

Make a pipe bender in the following sequence:

- prepare the pulleys. To create a universal device, that is, suitable for working with pipes of different diameters, use 2 triple pulleys: a pair for pipes three quarters of an inch, a pair for half inches and a pair for inch pipes.

Advice! Order such pulleys in the workshop, because you will not find them on sale.

In the wheel on each side there should be a groove the size of half the diameter of the pipe. Since the bend is formed by a stationary roller to minimize the radius of the arc, the diameter of this element should be as small as possible;

- Next, make a base, which is a plate, at the corners of which holes are drilled for attachment to the desktop. Use a metal sheet about 10 millimeters thick for this;

- then, using welding, install a pin in the center of the plate. Its diameter should correspond to the internal section of the small triple pulley;

- after the manufacture of the bed, a rotary mechanism is performed. First of all, from 2 metal plates, boil the U-shaped part. The height of its legs should correspond to the diameter of the large and small pulley. In this case, it is necessary to control the possibility of placing at this distance a large movable pulley and half stationary;

- weld a handle about 25 centimeters long to the top of the part. Subsequently, a pipe playing the role of a lever will be put on it;

- Having done this, install a large pin with the edge of the part and secure it with cotter pins. A small pulley is mounted on the base pin simultaneously with the entire structure;

- focus. To do this, weld another pin, then put the pulley on it.

This completes the manufacture of the tool. It remains only to fix the manual pipe bender and begin work on bending pipes.

Features of bending with a homemade tool

When bending pipes, you must know the principles of the process and the diameter of the products. Then the correct deformation of the material without wrinkles and tears will be ensured. On machines where hydraulics are used, bending with heating is possible.This allows you to bend pipes made of polymers, strong alloys, as well as products with a sufficiently large wall thickness. But in practice, at home, the “cold” method is often used, oriented to work with pipe products made of plastic material - aluminum, copper, metal plastic. However, it is possible to bend from another metal with the exception of cast iron. In this case, to get a quality bend, before the deformation procedure, water (ice) is poured into the pipe, oil or salt or sand is poured.

The minimum bending radii are indicated in the tables below: the first contains data on copper and brass pipes, and the second on steel.

Table 1

| L min | R | d | |

| 60 | 90 | 30 | |

| 55 | 72 | 24 | |

| 50 | 36 | 18 | |

| 45 | 30 | 15 | |

| 35 | 24 | 12 | |

| 30 | 20 | 10 | |

| 25 | 16 | 8 | |

| 18 | 12 | 6 | |

| 12 | 8 | 4 | |

| 10 | 6 | 3 | |

table 2

| D | R if wall thickness | |

| Exceeds 2 mm | Up to 2 mm | |

| 60-140 | 5d | — |

| 35-60 | 4d | — |

| 20-35 | 3d | 5d |

| 5-20 | 3d | 4d |

In the tables: L min - the length (minimum) of the straight section; R is the smallest bending radius; d is the diameter of the workpiece. The unit of measurement for all indicators is millimeters.

Any pipe can be bent with a homemade pipe bender, but you need to take into account their diameter and the maximum possible bending radius

Non-standard methods of bending a profile pipe

To get a high-quality bend of a profile pipe at home, masters often use a welding machine and an ordinary grinder.

Work begins with calculating the required bend radius. Then, with the help of a grinder, cuts are carried out along the entire length of the selected site from three sides. After that, the workpiece can be bent at the required angle without much difficulty. In order for this parameter to be the most accurate, it is better to use a wooden piece of the desired shape. We apply it to the whole side of the pipe, fix it, and carefully bend it. At the same time, keep in mind that with an increase in the frequency of cuts, the smoothness of the bend increases.

Welding machine closes the cuts, and the resulting bumps are ground. Welding should be applied not just to cover the cracks, but so that the connection is guaranteed to be strong. This method, when properly executed, provides impressive results. However, it is suitable for isolated cases.

Note! If you have to work continuously with a large flow of workpieces, it is better to manufacture or purchase a special tool.

Qualitatively bend the pipe will help internal countermeasures. If the workpiece has a small radius of the circumference described around the profile, then a specially made spring can be used as a pipe bender.

In this case, the steel wire with a millimeter diameter acts as the starting material. She curls into a spring not with a round but a square section. The length of the side should be less than the size of the inner diameter of the profile pipe by 2 millimeters, so that the spring can fit inside without hindrance. Next, heat the spot with a blowtorch and bend using a piece of the required diameter.

Independently make a pipe bending machine under the power of each home master. And it’s not scary that this work will take some time. After all, this tool is really useful in the household and will probably come in handy more than once.