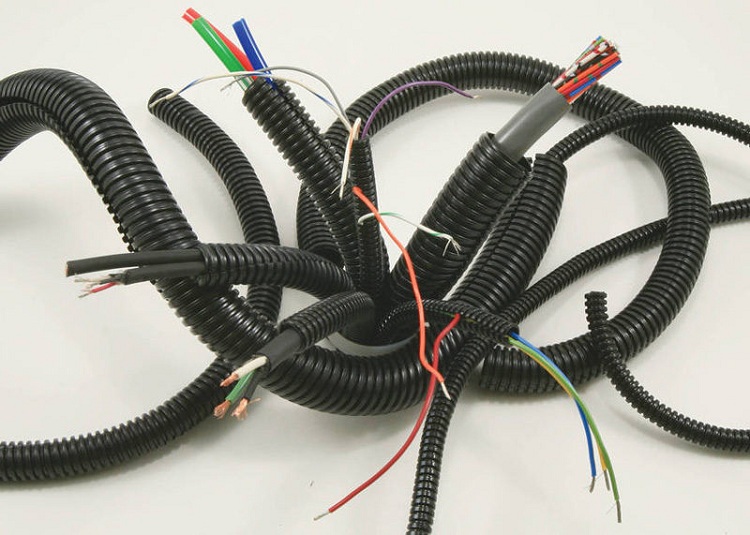

A corrugated pipe made of polyvinyl chloride (PVC) is a product that is used to protect various cable wiring. Besides the fact that it acts as a protective case that protects the wiring from mechanical stress, it also has dielectric properties. Pulling cable wiring in such pipes is simple, therefore corrugations are so popular in the modern building materials market.

Content

What is a polyvinyl chloride corrugated pipe?

PVC corrugation is a polymer product that has gained immense popularity due to its high technical characteristics and low price. The operational field of application of PVC corrugated pipes is quite wide, which is associated with a large assortment of these products.

Consider two main areas in which PVC corrugations are widely used:

- First of all, such products are used to create a protective channel for low-current or power cable wiring. Such electrical systems can be either direct or alternating current. The voltage in them can reach 1000 V.

Helpful information! In addition, polyvinyl chloride corrugated pipes are used in the installation of internal or external wire telephone and other networks.

- the second way to use this corrugated product is an element of drainage sewer communication. Corrugated pipes in such systems are used for wastewater.

PVC corrugated pipes have a good coefficient of flexibility, which contributes to their installation even in confined spaces. This property allows you to reduce labor costs and installation time.

The corrugation of small diameter is characterized by good flexibility, which allows you to lay it without using corners to turn

Varieties of PVC corrugation

Plastic corrugated pipe for cable made of polyvinyl chloride is used when laying electrical communications of open or closed type. Depending on the design features, the following varieties of these products are distinguished:

- single layer;

- two-layer.

In a single-layer device, the outer and inner surfaces have a common wall. Two-layer products consist of two walls: internal smooth and external corrugated. Thanks to this design, double-layer PVC corrugated tubes are characterized by good rigidity. The smooth inner wall allows electrical cables to be pulled through the corrugated pipe without resistance.

All corrugated PVC products are classified by one more indicator - the method of execution. According to the method of execution, two main types of corrugated pipe from polyvinyl chloride are distinguished:

- lungs;

- heavy (reinforced).

The first version of the corrugated pipe is popular in the installation of systems inside various structures. They are distinguished by the highest coefficient of flexibility, and are also thin-walled, which allows them to be freely mounted on various bends. They are often used for wiring electric cables under the skin of walls and ceilings.

Heavy polyvinyl chloride corrugated tubes are distinguished by thick walls and high strength characteristics. They are usually mounted in more difficult conditions. For example, they are laid in a cement screed or underground.

Heavy type pipes are used for laying underground utilities and those systems that work in difficult conditions

In order to maximally facilitate the pulling of cable wiring through the corrugated tubes, special devices are used that are part of the corrugation probes. The probe is an element made of steel and is a cable that secures the cable and allows you to stretch it to the other side of the pipe. In this case, the laying of the electrical network is several times faster, however, some companies produce corrugated pipelines that are not equipped with these probes. If we compare pipes with probes and products without them, then, in terms of quality, they are identical, but the cost of the second is lower.

Polyvinyl chloride corrugations have a wide range of sizes. The cross-sectional indicators of such pipes vary from 16 to 63 mm. Such pipes are sold, as a rule, in special coils (bays), the length of which can be different (from 15 to 100 m). For reliability, such coils are wrapped with a special plastic film. Rigid corrugated tubes are available in lengths of 2 to 3 m.

Advantages and disadvantages of PVC corrugated pipe

Each product has its own advantages and disadvantages. This also applies to polyvinyl chloride corrugated pipe, which have many advantages and some disadvantages. Consider the advantages of using flexible corrugated PVC pipes for cable laying:

- the operational life of such products can reach up to 50 years under normal use and over time they do not lose their technical characteristics;

- have a high coefficient of moisture resistance;

- relate to low flammable materials, and when ignited, they differ in self-extinguishing;

- have high resistance to mechanical stress (for example, shock);

- have excellent resistance to the harmful effects of corrosion;

- possess resistance to aggressive chemical compounds;

- during operation, they do not emit any substances that can cause harm to human health, therefore they are considered environmentally friendly;

- the small mass of such products contributes to their storage, transportation and installation;

- due to its properties, they are used for quick repair work in power grids;

- universality of polyvinyl chloride corrugated pipe.

Even light corrugation has high strength, which allows it to be mounted inside walls, floors and floors

Note! The dielectric properties of these products allow them to withstand voltages that can reach 2000 V, under the conditions that the insulation has a resistance of 100 ohms.

These pipes, of course, are very popular, but they also have some disadvantages. Consider them:

- polyvinyl chloride corrugated pipes are characterized by poor resistance to temperature extremes, as well as to high temperatures. Cable laying in such pipes is allowed to be carried out at an ambient temperature of not lower than - 5 and not higher than + 45 ° C.

- PVC pipe has a weak resistance to ultraviolet radiation. In this regard, experts do not recommend mounting it in the open. However, reinforced polyvinyl chloride corrugations can do better with ultraviolet rays.

Tips for choosing PVC corrugated pipe

The choice of corrugated PVC pipes for cables is an important event, which should be approached with all seriousness and care so as not to stumble on low-quality or defective products.

The size of the protective corrugated pipe made of polyvinyl chloride must be selected individually for a particular case.This is due to the fact that this parameter depends on the indicator of the cable cross-section, as well as on the number of cables and their purpose (this pattern is described in the table below).

Table 1

| Wire cross section, mm² | Number of wires, pcs | External indicators of the cross section of the corrugation, mm |

| 35 | 2 to 5 | 40, 50, 63 |

| 25 | 32, 40, 50 | |

| 16 | 32, 40 | |

| 10 | 25,32,40 | |

| 4 | 20, 25 | |

| 2,5 | 16, 20, 25 | |

| 1,5 | 16, 20 |

Corrugated plastic pipes for cables with a cross-sectional index of 16 mm are best suited for laying wires to lighting equipment. For laying to switches and sockets, as a rule, products with a cross-sectional index of 20 mm are used. If several electrical cables are located in the corrugation, it is recommended to use flexible corrugated tubes with different cross-sectional indicators calculated according to the table.

It is recommended to buy a corrugated product equipped with a steel probe. This will minimize labor costs during the installation of the power grid, as well as save laying time.

Tips for installing and operating PVC corrugated pipes for cable laying

Laying such products is not particularly difficult. If you want to lay such pipes, each person who does not have special construction knowledge and skills will be able to lay. However, not everyone understands the nuances of wiring electrical communications. Therefore, it is recommended to hire a specialist for such an event.

When installing suspended building structures or when plastering walls and ceilings with plasterboard, as a rule, the corrugated PVC pipe is laid in special gates (channels). An open installation option for electric systems of corrugated pipes and cables located inside them is often used in home systems.

Note! Polyvinyl chloride corrugations for cable wiring are allowed to be mounted inside and outside of any building structures. This is due to the fact that such products are fire resistant. But if possible, their laying inside non-combustible materials is recommended. Reinforced models of corrugated pipes are used in conditions of increased mechanical load.

Consider the phased installation of an electric cable in the corrugation:

- First of all, the corrugation for the electric cable is laid.

- Next, the power cable is twisted at the end of the broaching element (probe).

- Finally, carefully pull out the cable on the other side of the corrugation.

With the hidden installation of polyvinyl chloride corrugated pipes for laying the cable, they are fixed with cement mortar, and with the open laying - with the help of special fixing clamps.